Preparation method of decoquinate solution

A decoquinate and solution technology, applied in the field of preparation of decoquinate solution, can solve the problems of complicated technical process, high temperature and high pressure sterilization in the preparation process, etc., and achieves simple preparation process, good prevention of poultry coccidiosis, and good effect. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

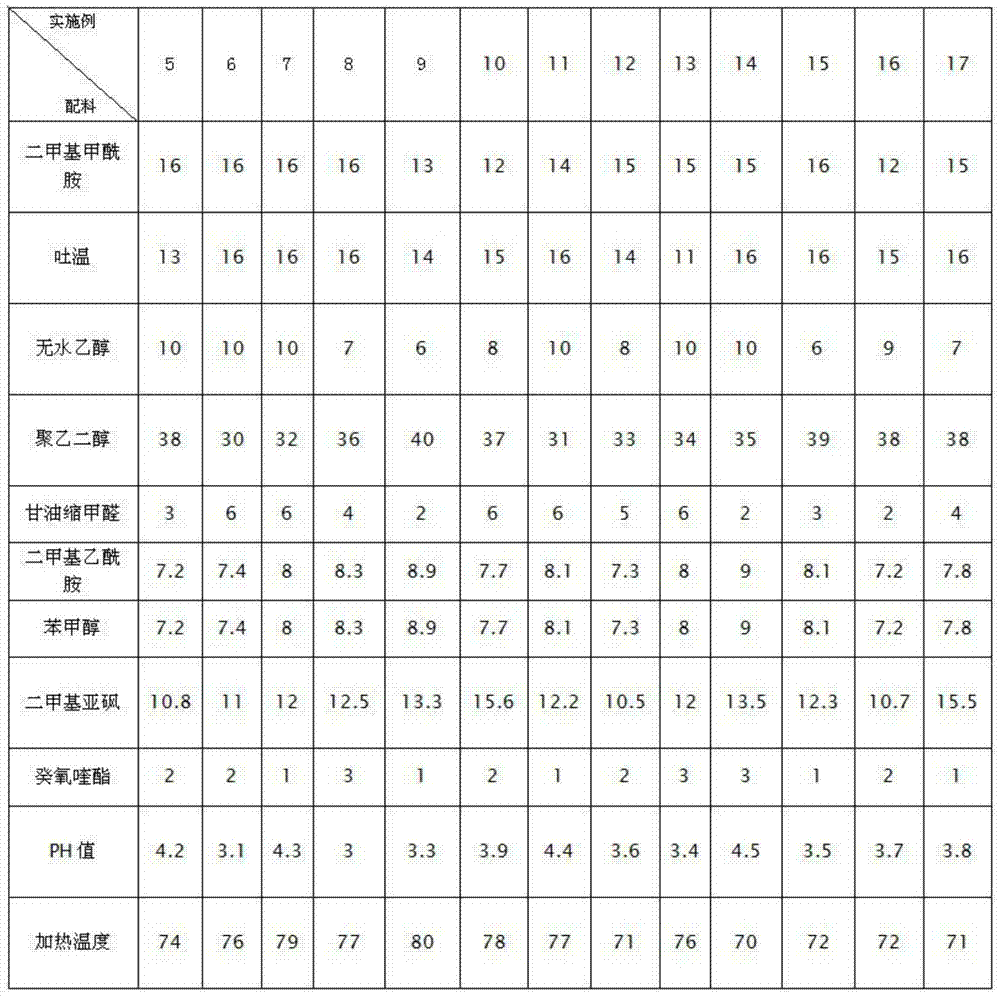

Examples

Embodiment 1

[0012] A preparation method of decoquinate solution, comprising solvent, cosolvent, pH regulator, solvent is dimethylformamide, Tween, dehydrated alcohol, polyethylene glycol, glycerol formal, and its mass ratio is ( 5~8):(5~8):(3~5):(15~20):(1~3); Cosolvent is dimethylacetamide, benzyl alcohol, dimethyl sulfoxide, its mass ratio is 2:2:3; the mass ratio of solvent, co-solvent, and decoquinate is (75~80):(25~31):(1~3); Preparation:

[0013] (1) Stir dimethylformamide and co-solvent evenly, then add decoquinate and stir to dissolve, adjust the pH value of the mixed solution to 3.0-4.5 with a pH regulator, and stir evenly for later use;

[0014] (2) Add absolute ethanol to polyethylene glycol, heat and stir, add glycerin formal after 30 minutes, and heat at 70°C-80°C;

[0015] (3) Evenly mix the solution prepared in step (1) and step (2), cool naturally to room temperature, add Tween and stir evenly, then fine filter and pot.

[0016] The pH regulator is hydrochloric acid wit...

Embodiment 2

[0018] A preparation method of decoquinate solution, comprising solvent, cosolvent, pH regulator, solvent is dimethylformamide, Tween, dehydrated alcohol, polyethylene glycol, glycerin formal, and its quality is 11Kg, 10Kg, 9Kg, 40Kg, 6Kg; cosolvents are dimethylacetamide, benzyl alcohol, dimethyl sulfoxide, and its quality is 9Kg, 9Kg, 13Kg; the above preparations are prepared under normal temperature and pressure according to the following steps:

[0019] (1) Stir dimethylformamide and cosolvent evenly, then add 2Kg decoquinate and stir to dissolve, adjust the pH value of the mixed solution to 4 with a pH regulator, and stir evenly for later use;

[0020] (2) Add absolute ethanol to polyethylene glycol, heat and stir, add glycerin formal after 30 minutes, and heat at 73°C;

[0021] (3) Evenly mix the solution prepared in step (1) and step (2), cool naturally to room temperature, add Tween and stir evenly, then fine filter and pot.

[0022] The pH regulator is hydrochloric a...

Embodiment 3

[0023] Embodiment 3: specific implementation steps are as shown in embodiment 2,

[0024] (1) 11Kg dimethylformamide, the cosolvent that 8.6Kg dimethylacetamide, 8.6Kg benzyl alcohol, 13Kg dimethyl sulfoxide are formed are stirred evenly, then add 3Kg decoquinate and stir to dissolve, with a concentration of 10 %-25% hydrochloric acid to adjust the pH value of the mixed solution to 4, and stir evenly for later use;

[0025] (2) Add 9Kg of absolute ethanol into 39Kg of polyethylene glycol, heat and stir, add 6Kg of glycerol formal after 30 minutes, and heat at 75°C;

[0026] (3) Evenly mix the solution prepared in step (1) and step (2), cool naturally to room temperature, add 12Kg Tween and stir evenly, then fine filter and pot.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com