Super-hydrophobic and anti-icing carbon fiber board and preparation method thereof

A carbon fiber board, super-hydrophobic technology, applied in the field of interface chemistry, can solve the problems affecting the service life of carbon fiber board and the failure of carbon fiber board materials, and achieve the effects of large-scale production, reduction of free energy, and short preparation period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

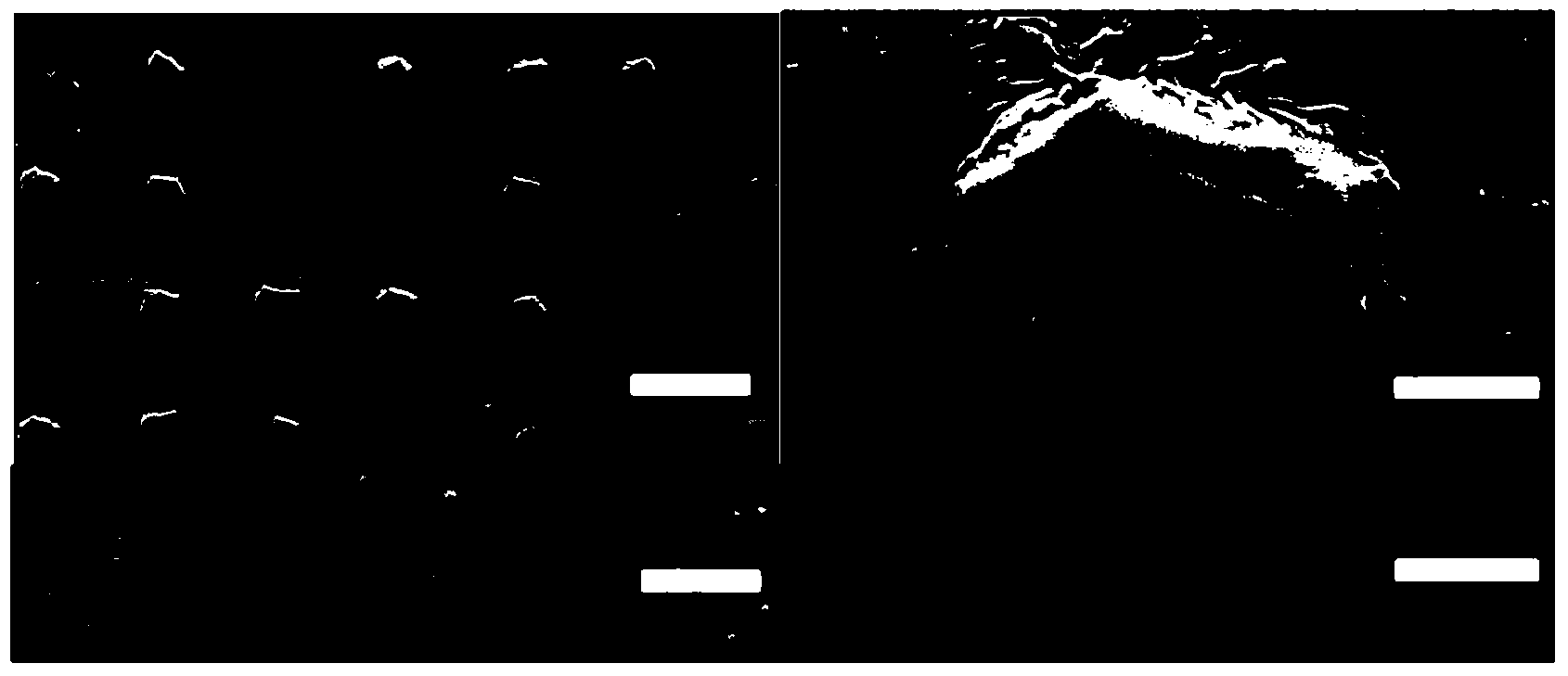

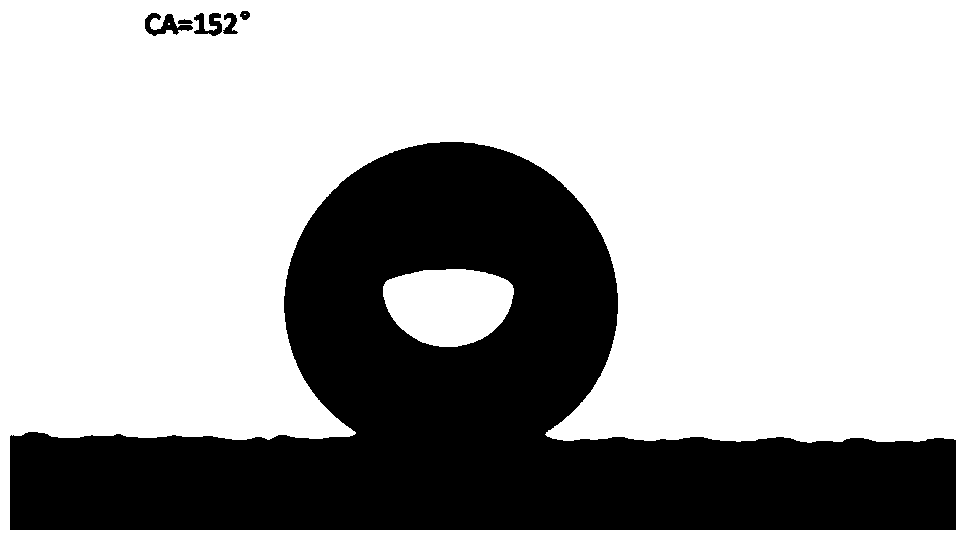

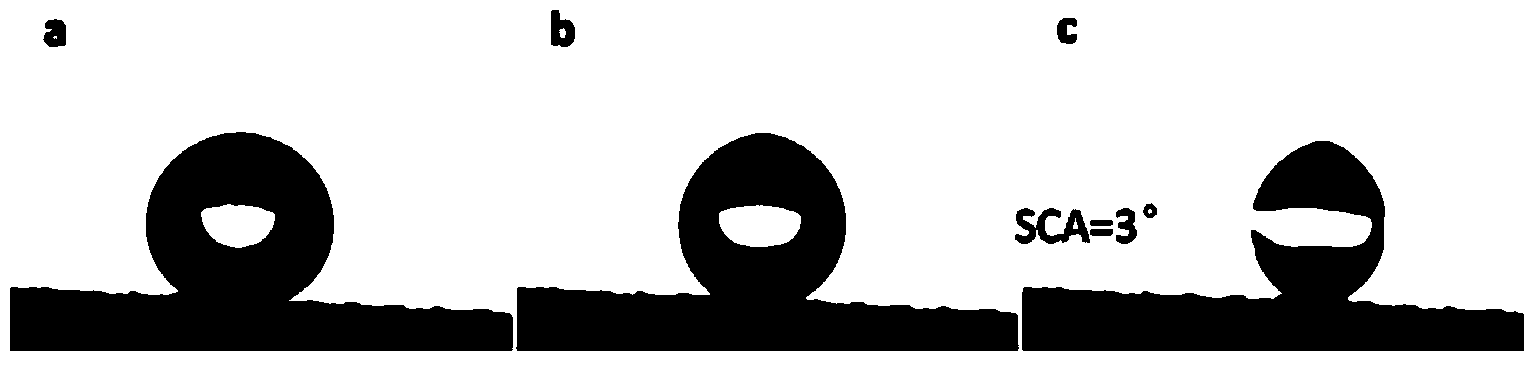

Method used

Image

Examples

Embodiment 1

[0050] The first step is the preparation of seed solution;

[0051] At the stirring speed of 300 rpm provided by the magnetic stirrer, take 0.3 g of zinc acetate and dissolve it in 20 mL of ethanolamine. After stirring for 20 minutes, the solution appears transparent, then add 25 mL of ethylene glycol methyl ether and continue stirring for 12 minutes. Stir evenly to obtain the seed solution;

[0052] The second step is the preparation of growth solution;

[0053] At the stirring speed of 300 rpm provided by the magnetic stirrer, add 0.3 g of zinc nitrate to 100 mL of deionized water. After stirring for 20 minutes, the solution appears transparent, then add 0.8 g of hexamethylenetetramine and continue stirring Stir evenly after 20 minutes to obtain the growth solution;

[0054] The third step is the pretreatment of carbon fiber board CFB;

[0055] (A) Wash the carbon fiber board CFB with 30% ethanol for three times, the purpose is to remove the dirt on the surface of the CFB, which is ...

Embodiment 2

[0069] The first step is the preparation of seed solution;

[0070] Dissolve 0.15 g of zinc acetate in 10 mL of ethanolamine at a stirring speed of 200 rpm provided by the magnetic stirrer. After stirring for 30 minutes, the solution appears transparent, then add 20 mL of ethylene glycol methyl ether and continue stirring for 30 minutes. Stir evenly to obtain the seed solution;

[0071] The second step is the preparation of growth solution;

[0072] At the stirring speed of 300 rpm provided by the magnetic stirrer, add 0.5 g of zinc nitrate to 100 mL of deionized water. After stirring for 30 minutes, the solution appears transparent, then add 0.6 g of hexamethylenetetramine and continue stirring Stir evenly after 30 minutes to obtain the growth solution;

[0073] The third step is the pretreatment of carbon fiber board CFB;

[0074] (A) Wash the carbon fiber board CFB with 70% ethanol with a volume fraction of 70%, the purpose of which is to remove the dirt on the surface of the CFB, ...

Embodiment 3

[0084] The first step is the preparation of seed solution;

[0085] Dissolve 0.45 g of zinc acetate in 20 mL of ethanolamine at a stirring speed of 500 rpm provided by the magnetic stirrer. After stirring for 10 minutes, the solution appears transparent, then add 30 mL of ethylene glycol methyl ether and continue stirring for 20 minutes. Stir evenly to obtain the seed solution;

[0086] The second step is the preparation of growth solution;

[0087] At a stirring speed of 500 rpm provided by the magnetic stirrer, add 0.45 g of zinc nitrate to 100 mL of deionized water. After stirring for 10 minutes, the solution appears transparent, then add 0.9 g of hexamethylenetetramine and continue stirring Stir evenly after 20 minutes to obtain the growth solution;

[0088] The third step is the pretreatment of carbon fiber board CFB;

[0089] (A) Wash the carbon fiber board CFB twice with 45% ethanol, the purpose of which is to remove the dirt on the surface of the CFB, which is also commonly kn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com