A kind of synthesis technique of 1-chloro-1'-chloroacetyl cyclopropane

A technology of chloroacetylcyclopropane and synthesis process, which is applied in the field of synthesis technology of 1-chloro-1'-chloroacetylcyclopropane, can solve the problems of being unsuitable for industrial scale-up production, low yield and the like, and achieves typical process conditions Controllable, easy to operate, and the effect of shortening the process cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

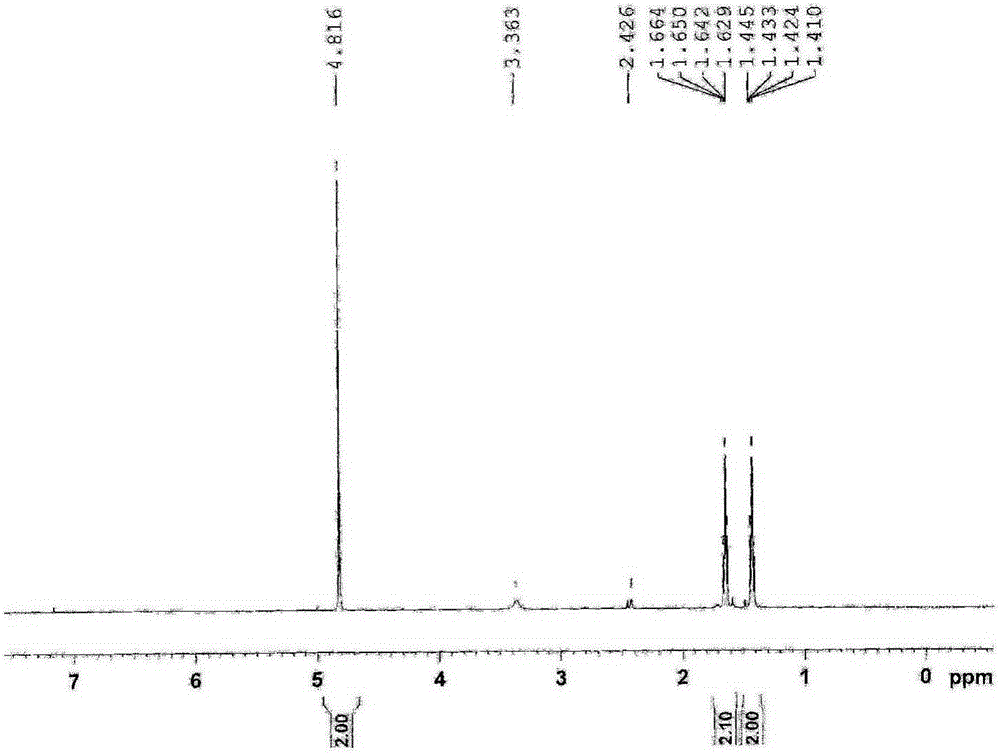

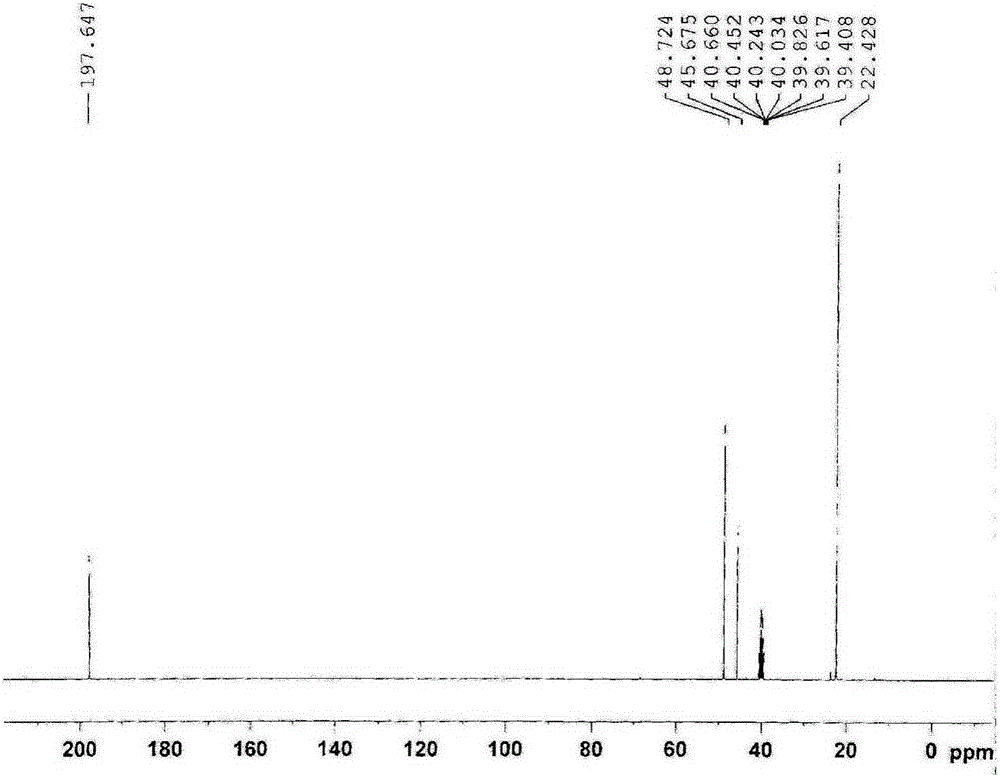

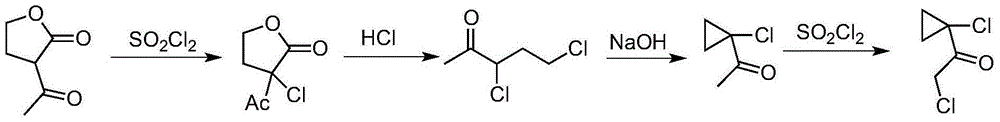

[0028] Synthesis of 1-chloro-1'-chloroacetylcyclopropane.

[0029] (1) Chlorination reaction I, synthesis of α-chloro-α'-acetyl-γ-butyrolactone

[0030] Add 3235.6g (25mol, 99%, 1.0eq) of α-acetyl-γ-butyrolactone into a 30L jacketed kettle equipped with mechanical stirring, thermometer and exhaust gas absorption device; reduce the temperature to 0℃ and start adding sulfonyl chloride dropwise 3408.3g (25mol, 99%, 1.0eq), temperature controlled not to exceed 30°C, stir for 2h after the dropwise addition is complete until the raw material conversion is complete; after the reaction is completed, reduce the residual sulfonyl chloride, hydrochloric acid gas and sulfur dioxide to obtain the crude α -Chloro-α'-acetyl-γ-butyrolactone, 4060g, slightly yellow transparent liquid, with a purity of 99.5% and a crude yield of 100%.

[0031] (2) Ring opening reaction, synthesis of 3,5 dichloro-2-pentanone

[0032] Add 4060g α-chloro-α'-acetyl-γ-butyrolactone (25mol, 99.5%, 1.0eq) and 1669.2g (27.5mo...

Embodiment 2

[0040] Synthesis of 1-chloro-1’-chloroacetylcyclopropane

[0041] The addition amount and condition control of the reaction materials in each step are the same as in Example 1. The organic solvent used in the ring-opening reaction is toluene, so the reaction solvent in other subsequent steps is toluene. The four-step total yield of the product is 101.7%*80%*82%*70%=46.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com