Polyimide adhesive and preparation method thereof

A polyimide and adhesive technology, applied in the direction of adhesives, etc., can solve the problems of limited application, low peel strength, and low adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0066] The present invention provides a kind of preparation method of polyimide adhesive described in above-mentioned technical scheme, comprises the following steps:

[0067] Mixing a diamine having a structure shown in formula II and a first organic solvent to obtain a diamine solution;

[0068] Polymerizing the diamine solution and the dianhydride having the structure shown in formula III to obtain the first polymer intermediate;

[0069] polymerizing the first polymer intermediate with a diamine having a structure shown in formula IV to obtain a second polymer intermediate;

[0070] The second polymer intermediate, the second organic solvent and the diamine having the structure shown in formula V are polymerized to obtain a polyamic acid solution;

[0071] Coating the polyamic acid solution, removing the first organic solvent and the second organic solvent, and then imidizing to obtain a polyimide adhesive;

[0072] h 2 N-R 2 -NH 2 Formula II; h 2 N-R 3 -NH 2 For...

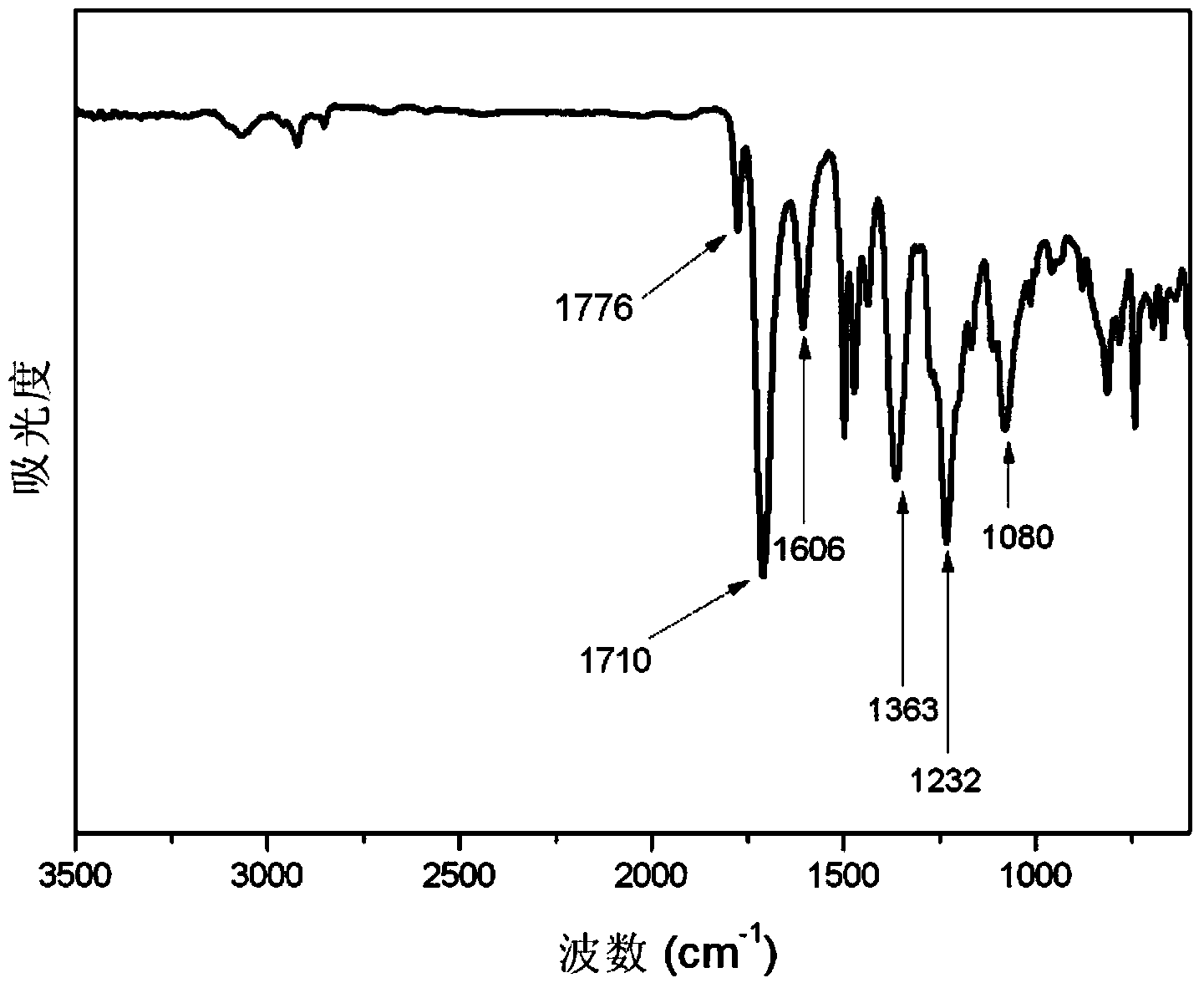

Embodiment 1

[0097] Add 2,5-bis(4-aminophenyl)pyridine (7.84g, 0.03mol) into 140g of N-methylpyrrolidone, stir and dissolve to obtain 2,5-bis(4-aminophenyl)pyridine solution ;

[0098] Add 3,3',4,4'-diphenyl ether tetracarboxylic dianhydride (31.02g, 0.10mol) to the 2,5-bis(4-aminophenyl)pyridine solution, stir and polymerize at 15°C Reaction 4h, obtains the first polymer intermediate;

[0099] Add 3,4'-diaminodiphenyl ether (12.01g, 0.06mol) to the first polymer intermediate, stir, and carry out polymerization reaction at 15°C for 6h to obtain the second polymer intermediate;

[0100] Add 70g of tetrahydrofuran to the second polymer intermediate, then add 1,3-diaminopropylhexamethyldisiloxane (2.48g, 0.01mol), stir, and carry out polymerization reaction at 15°C for 8h to obtain Polyamic acid solution;

[0101] The polyamic acid solution was salivated on the surface of the stainless steel plate, placed in an oven and dried at 80°C for 180 minutes; then, slowly heated to 300°C in the ove...

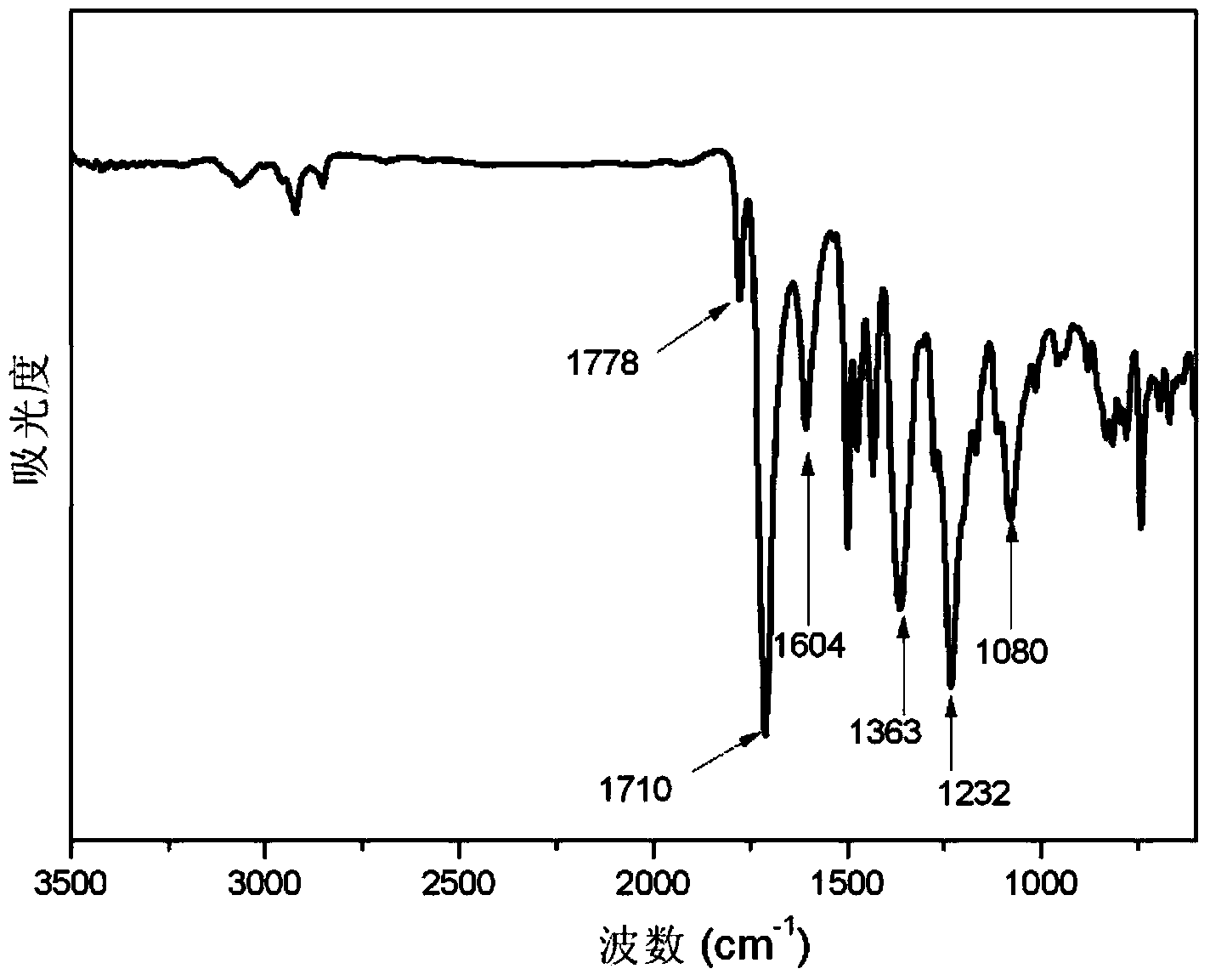

Embodiment 2

[0107] Add 2,5-bis(4-aminophenyl)pyrimidine (7.81g, 0.03mol) into 140g of N-methylpyrrolidone, stir and dissolve to obtain 2,5-bis(4-aminophenyl)pyrimidine solution ;

[0108] Add 3,3',4,4'-diphenyl ether tetracarboxylic dianhydride (31.02g, 0.10mol) to the 2,5-bis(4-aminophenyl)pyrimidine solution, stir and polymerize at 15°C Reaction 4h, obtains the first polymer intermediate;

[0109] 1,3-bis(4-aminophenoxy)benzene (17.54 g, 0.06 mol) was added to the first polymer intermediate, stirred, and polymerized at 15°C for 6 hours to obtain the second polymer intermediate;

[0110] Add 70g of tetrahydrofuran to the second polymer intermediate, then add 1,3-diaminopropylhexamethyldisiloxane (2.48g, 0.01mol), stir, and carry out polymerization reaction at 15°C for 8h to obtain Polyamic acid solution;

[0111] The polyamic acid solution was salivated on the surface of the stainless steel plate, placed in an oven and dried at 80°C for 180 minutes; then, slowly heated to 300°C in the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Peel strength | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com