Energy-saving annealing furnace

An annealing furnace and furnace body technology, applied in the field of energy-saving annealing furnaces, can solve the problems of lowering the temperature of the annealing furnace, poor heat preservation effect, and high energy loss, and achieve the effects of preventing excessive pressure, safe and reliable use, and promoting gasification and volatilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

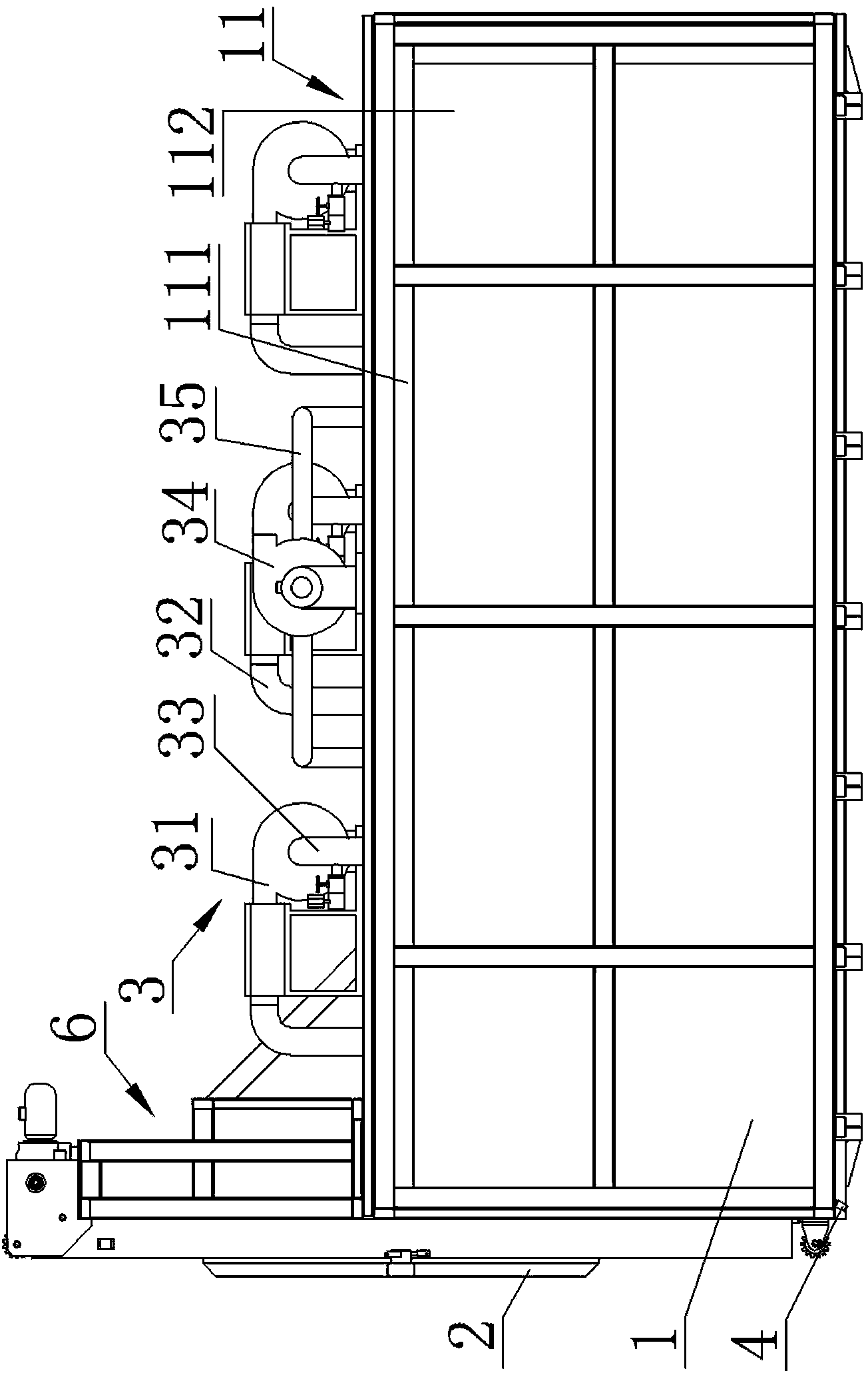

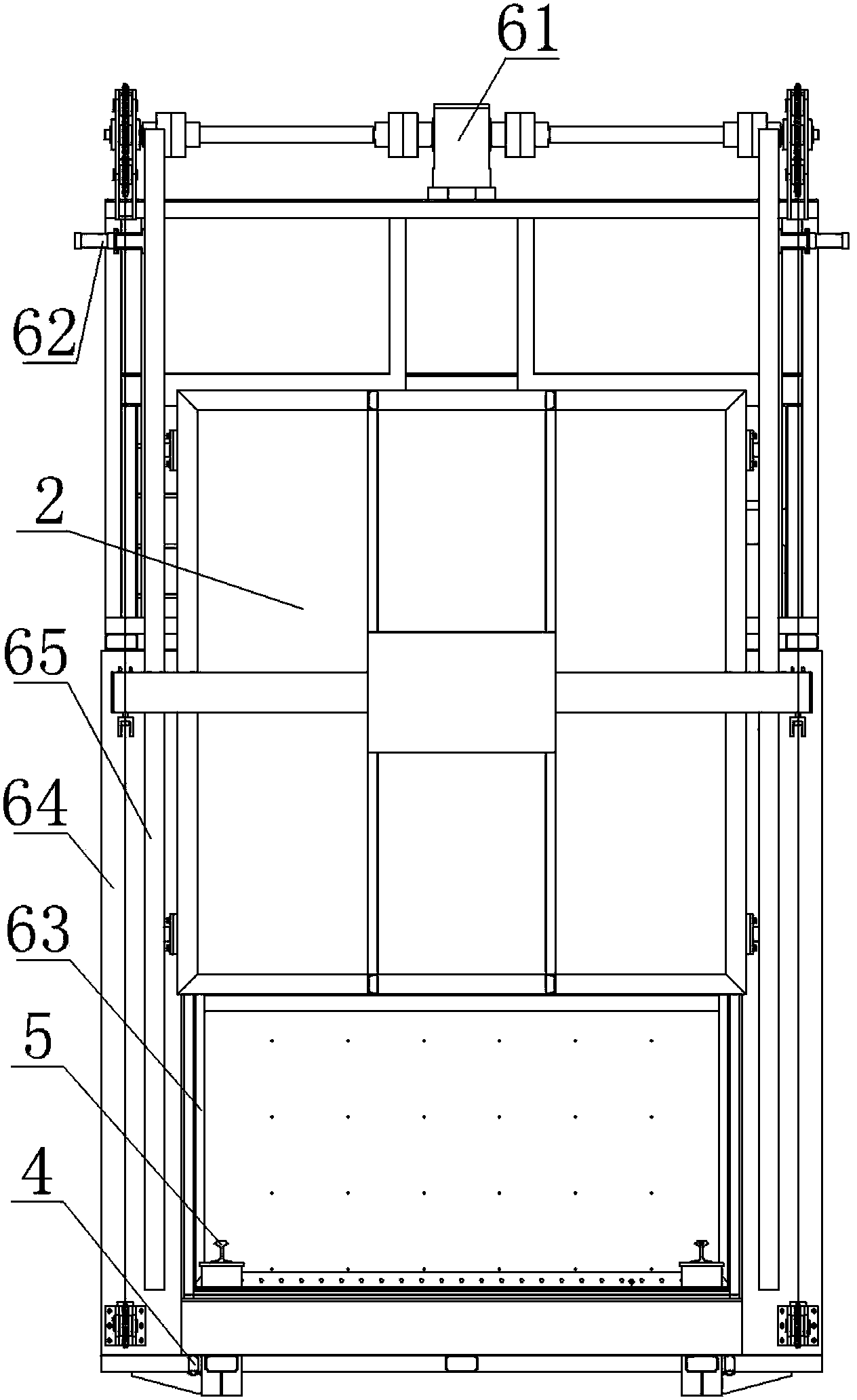

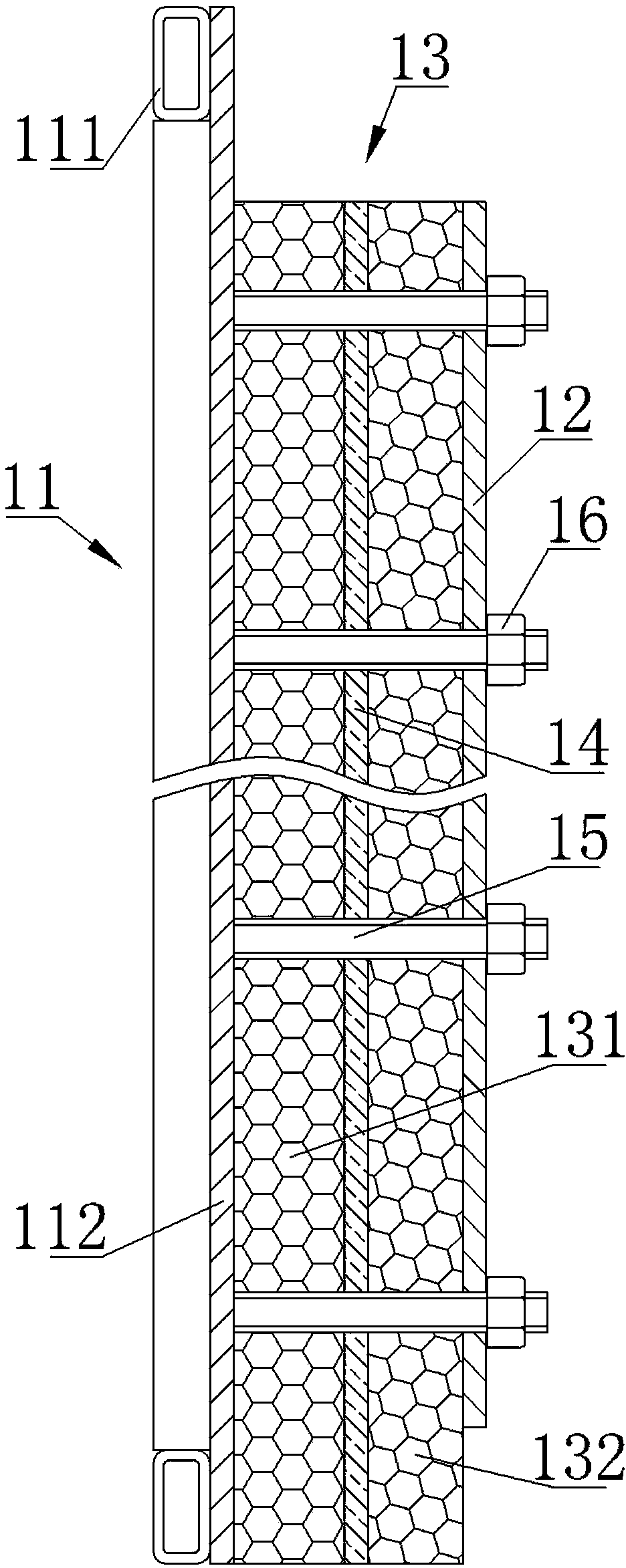

[0025] From Figure 1 to Figure 8 It can be seen that the energy-saving annealing furnace of the present invention includes a furnace body, a circulating heating system 3, a temperature control detection device 4 and a track 5, the furnace body includes a heat-insulating wall 1 and a furnace door 2, and the heat-insulating wall 1 includes an outer wall panel 11, Inner wallboard 12, thermal insulation cotton 13, thermal insulation aluminum foil 14, several screw rods 15 and several nuts 16 filled between the outer wallboard 11 and inner wallboard 12, thermal insulation cotton 13 includes a first thermal insulation cotton layer 131 and a second thermal insulation cotton layer 131 The cotton layer 132, the furnace door 2 is installed on the insulation wall 1 through the lifting device 6, the circulation heating system 3 includes a heating fan 31, a hot air pipe 32, a return air pipe 33, a negative pressure fan 34 and a negative pressure air pipe 35, and the outer wall The board 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com