High-reliability data flexible cable used for building

A reliable and flexible cable technology, applied in the field of high-reliability data flexible cables, can solve the problems of poor thermal stability and radiation resistance, difficult to take into account at the same time, easy to damage the cable core, etc., to improve weather resistance Sexuality and flame retardancy, improved reliability and service life, improved thermal stability effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

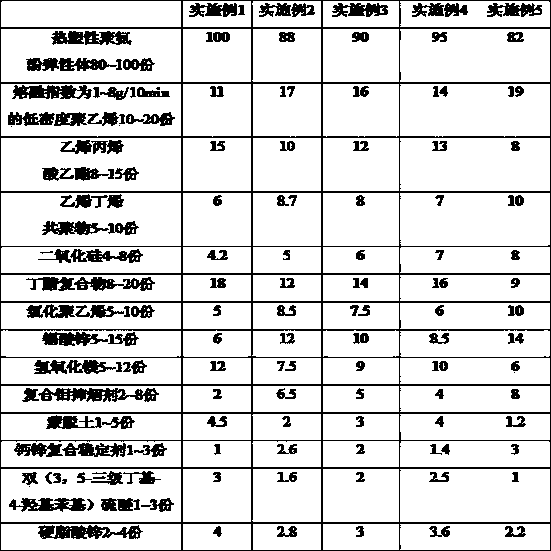

Embodiment 1~5

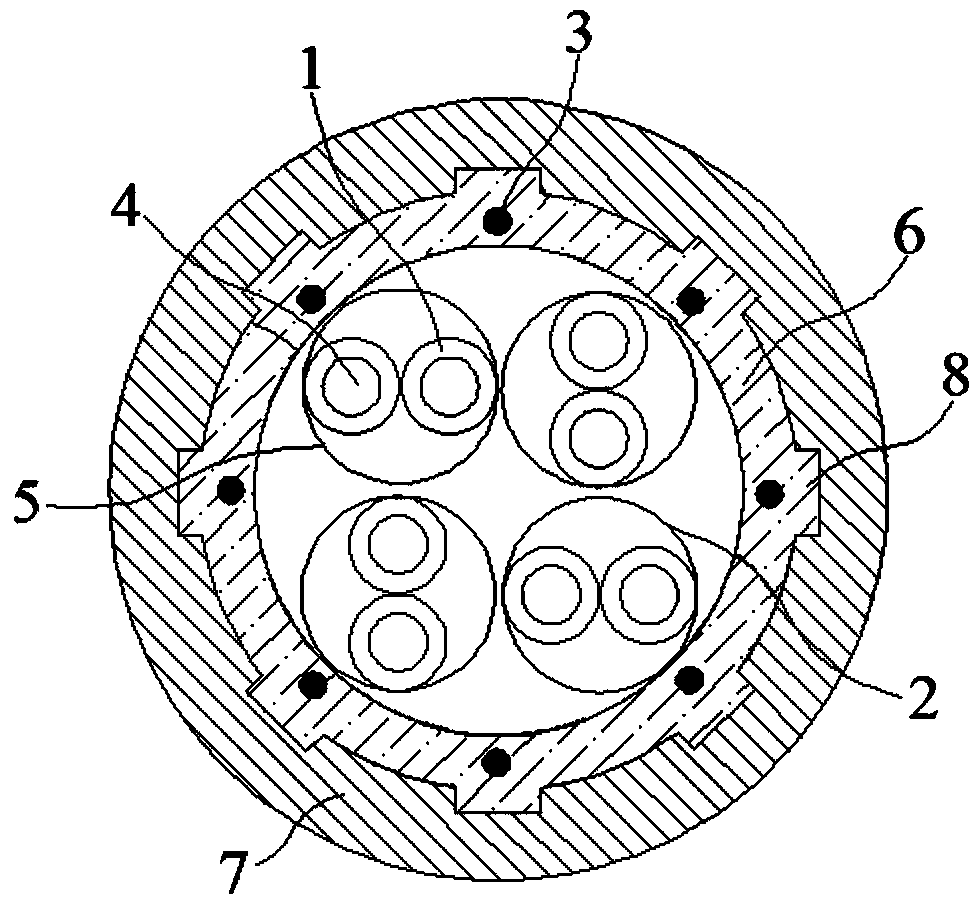

[0047] Embodiments 1 to 5: A high-reliability data flexible cable for buildings, including four core wires 2, the core wires 2 are composed of two conductive units 4 covered with an insulating layer 1, the core wires 2 The outer surface is wrapped with polyester tape 5;

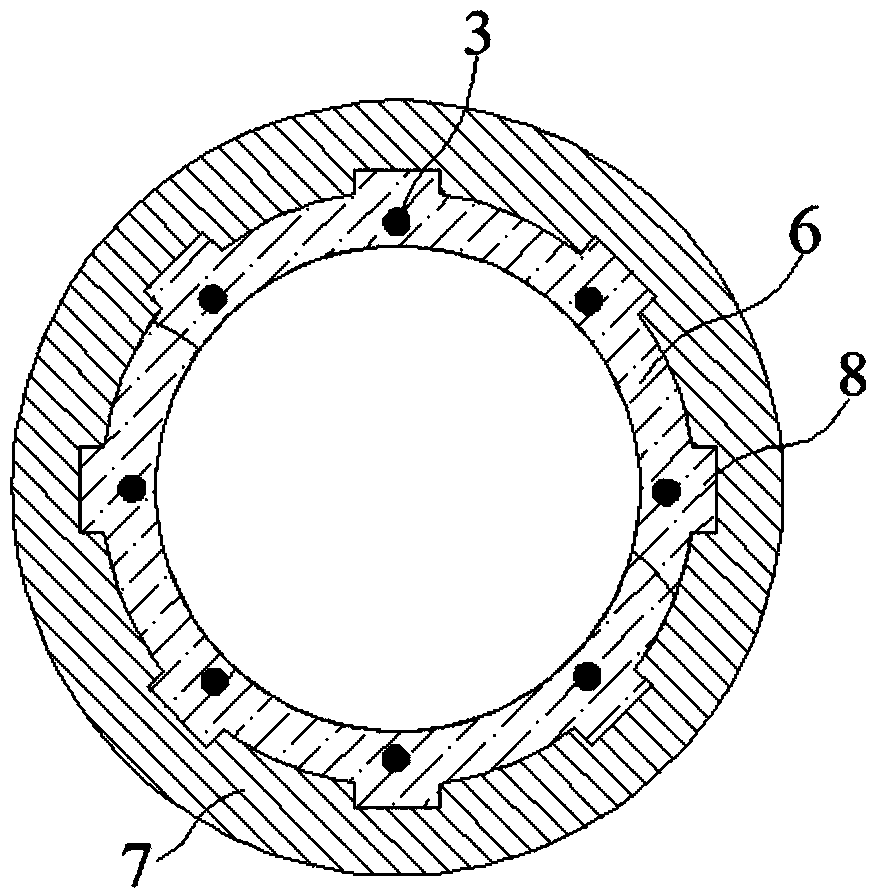

[0048] A polyvinyl chloride layer 6 is coated on the outer surfaces of the four core wires 2, a thermoplastic polyurethane layer 7 is coated on the outer surfaces of the polyvinyl chloride layers 6, and the polyvinyl chloride layer 6 is in contact with the thermoplastic polyurethane layer 7 Several bumps 8 are uniformly distributed along the circumference of the surface of the polyvinyl chloride layer 6, and several polyethylene ropes 3 are distributed along the circumference of the polyvinyl chloride layer 6 .

[0049] The number of bumps 8 on the surface of the polyvinyl chloride layer 6 is 8, and the thickness of the thermoplastic polyurethane layer 7 is greater than that of the polyvinyl chloride layer 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com