Injection molding method of ceramic die core of wire drawing die

A technology of injection molding and wire drawing die, which is applied in the field of mold manufacturing and can solve problems such as parameter selection and implementation process are not perfect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

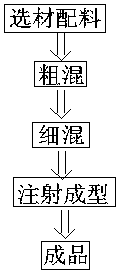

[0018] The specific operation process of the injection molding method of the ceramic wire drawing die core mentioned in the present invention is as follows:

[0019] a) Material selection and ingredients, materials include main material and binder, the percentage ratio of the two is: 80%: 20%; among them, the main material is made of Al2O3 powder, toughening agent ZrO2, active agent AS, through a ball mill After treatment, the powder with a particle diameter of 1.8-2.2um is obtained; the main components of the binder and their percentages are: thermoplastic resin 19%, plasticizer 4%, lubricant 76%, surfactant 1 %; The plastic resin is made of polystyrene, the plasticizer is made of dibutyl titanate, the lubricant is made of zinc stearate, and the surfactant is made of vegetable oil;

[0020] b) Coarse mixing, the process is as follows: First, pour the lubricant in the binder into the mixing tank, and control the temperature of the mixing tank at about 100°C to melt the lubrica...

Embodiment 2

[0024] The specific operation process of the injection molding method of the ceramic wire drawing die core mentioned in the present invention is as follows:

[0025] a) Material selection and ingredients, materials include main material and binder, the percentage ratio of the two is: 82%: 18%; among them, the main material is made of Al2O3 powder, toughening agent ZrO2, active agent AS, through a ball mill After treatment, the powder with a particle diameter of 1.8-2.2um is obtained; the main components of the binder and their percentages are: thermoplastic resin 18%, plasticizer 5%, lubricant 75.5%, surfactant 1.5% %; Plastic resin is selected from cellulose acetate, plasticizer is selected from fatty acid ester, lubricant is selected from paraffin, surfactant is selected from animal oil;

[0026] b) Coarse mixing, the process is as follows: First, pour the lubricant in the binder into the mixing tank, and control the temperature of the mixing tank at about 110°C to melt the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com