A microwave-absorbing asphalt pavement mixture and preparation method thereof

An asphalt pavement and microwave absorbing technology is applied in the field of pavement functional materials, which can solve the problems of high cost, energy waste, low deicing and snow removal efficiency, etc., to enhance the ability to absorb microwaves, improve the ability to absorb microwaves, and improve strength and stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

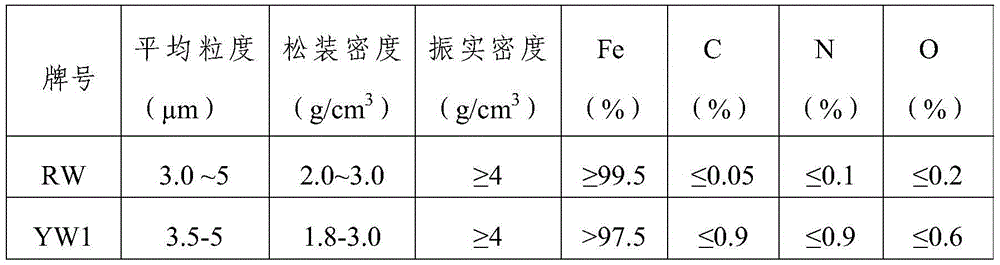

[0021] The asphalt pavement mixture that absorbs microwaves in this embodiment is made of the raw materials in the following mass percentages: 5% modified asphalt, 46% coarse aggregate, 40% fine aggregate, 2% mineral powder, and 7% hydroxyl iron powder; The above-mentioned modified asphalt is SBS modified asphalt, and the gradation type of the microwave-absorbing asphalt pavement mixture in this embodiment is AC-13.

[0022] The method for preparing the microwave-absorbing asphalt pavement mixture in this embodiment comprises the following steps:

[0023] Step 1. Preheat modified asphalt to 165°C, mix mineral powder and hydroxyl iron powder and preheat to 190°C, mix coarse aggregate and fine aggregate and preheat to 200°C;

[0024] Step 2: Mix the preheated mineral powder, hydroxyl iron powder, modified asphalt, coarse aggregate and fine aggregate in step 1, and then stir for 60 seconds to obtain a microwave-absorbing asphalt pavement mixture.

Embodiment 2

[0029] The asphalt pavement mixture that absorbs microwaves in this embodiment is made of the raw materials in the following mass percentages: 4.5% modified asphalt, 41.5% coarse aggregate, 45% fine aggregate, 4% mineral powder, and 5% hydroxyl iron powder; The above-mentioned modified asphalt is SBR modified asphalt, and the gradation type of the microwave-absorbing asphalt pavement mixture in this embodiment is AC-13.

[0030] The method for preparing the microwave-absorbing asphalt pavement mixture in this embodiment comprises the following steps:

[0031] Step 1. Preheat modified asphalt to 170°C, mix mineral powder and hydroxyl iron powder and preheat to 185°C, mix coarse aggregate and fine aggregate and preheat to 195°C;

[0032] Step 2: Mix the preheated mineral powder, hydroxyl iron powder, modified asphalt, coarse aggregate and fine aggregate in step 1, and then stir for 60 seconds to obtain a microwave-absorbing asphalt pavement mixture.

Embodiment 3

[0034] The asphalt pavement mixture that absorbs microwaves in this embodiment is made of the raw materials in the following mass percentages: 5.5% modified asphalt, 50% coarse aggregate, 35.5% fine aggregate, 3% mineral powder, and 6% hydroxyl iron powder; The above-mentioned modified asphalt is SBS modified asphalt, and the gradation type of the microwave-absorbing asphalt pavement mixture in this embodiment is AC-13.

[0035] The method for preparing the microwave-absorbing asphalt pavement mixture in this embodiment comprises the following steps:

[0036] Step 1. Preheat modified asphalt to 170°C, mix mineral powder and hydroxyl iron powder and preheat to 185°C, mix coarse aggregate and fine aggregate and preheat to 190°C;

[0037] Step 2: Mix the preheated mineral powder, hydroxyl iron powder, modified asphalt, coarse aggregate and fine aggregate in step 1, and then stir for 60 seconds to obtain a microwave-absorbing asphalt pavement mixture.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com