Preparation method of nano-zinc oxide with good photocatalytic effect performance

A technology of nano-zinc oxide and photocatalysis, applied in chemical instruments and methods, zinc oxide/zinc hydroxide, physical/chemical process catalysts, etc., can solve the problem of reducing the quality of nano-zinc oxide, poor performance of nano-zinc oxide, Insufficient purity of zinc and other problems, to achieve the effect of enhancing photocatalytic ability, improving machinability, and improving surface morphology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

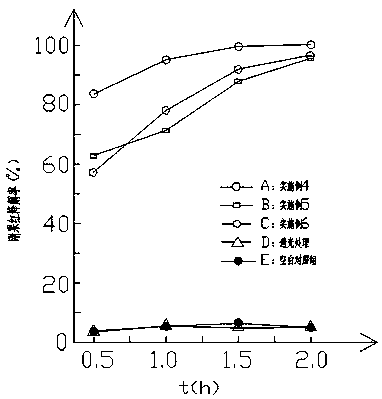

Examples

preparation example Construction

[0025] A method for preparing nano-zinc oxide with good photocatalytic effect performance, comprising the steps of:

[0026] (1) Preparation of powder A: Put the nano-graphite powder into the ultraviolet irradiation box for irradiation treatment, then filter it out and then immerse it in modification solution A and modification solution B for modification treatment, and finally filter Get powder A for later use;

[0027] (2) Preparation of nano-zinc oxide precursor compound: Mix urea solution and zinc sulfate solution together, then add powder A prepared in step (1), stir evenly and heat to keep the overall temperature at 80~85°C , heat preservation at this temperature for 1.5~2.5h, then centrifuge to obtain the nano-zinc oxide precursor compound, and finally dry it for later use;

[0028] (3) Preparation of nano-zinc oxide: put the nano-zinc oxide precursor compound prepared in step (2) into a microwave irradiation box for microwave radiation thermal decomposition treatment,...

Embodiment 1

[0030] A method for preparing nano-zinc oxide with good photocatalytic effect performance, comprising the steps of:

[0031] (1) Preparation of powder A: Put the nano-graphite powder into the ultraviolet irradiation box for irradiation treatment. During the irradiation treatment, control the irradiation power in the ultraviolet irradiation box to 800W, and control the wavelength of ultraviolet rays. 280~290nm, the length of irradiation treatment is controlled to 25min, then filtered out and then soaked in modified solution A and modified solution B for modification treatment, and finally filtered out to obtain powder A for later use; the modified The components and their corresponding parts by weight in the liquid A are: 15 parts of ethylene glycol, 2 parts of disodium ethylenediaminetetraacetic acid, and 95 parts of deionized water; the duration of soaking and modification treatment in the modification liquid A is 10 minutes; The components in the modified liquid B and their ...

Embodiment 2

[0035] A method for preparing nano-zinc oxide with good photocatalytic effect performance, comprising the steps of:

[0036] (1) Preparation of powder A: Put the nano-graphite powder into the ultraviolet irradiation box for irradiation treatment. During the irradiation treatment, control the irradiation power in the ultraviolet irradiation box to 800W, and control the wavelength of ultraviolet rays. 280~290nm, the duration of irradiation treatment is controlled to 25min, then filtered out and immersed in modified solution A for soaking modification treatment, and finally filtered out to obtain powder A for later use; each component in modified solution A And the corresponding parts by weight are: 15 parts of ethylene glycol, 2 parts of disodium edetate, and 95 parts of deionized water; the duration of soaking modification treatment in modification solution A is 10 minutes;

[0037] (2) Preparation of nano-zinc oxide precursor compound: Mix urea solution and zinc sulfate soluti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com