Polyolamine ester and its synthesis method and use

A technology of polyol amine ester and polyol amine is applied in the fields of cement admixtures, cement grinding aid production, and amine ester compounds, which can solve the problems of insignificant enhancement, restricting the development of grinding aids, etc., so as to improve compatibility The effect of improving the strength of cement and prolonging the action time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

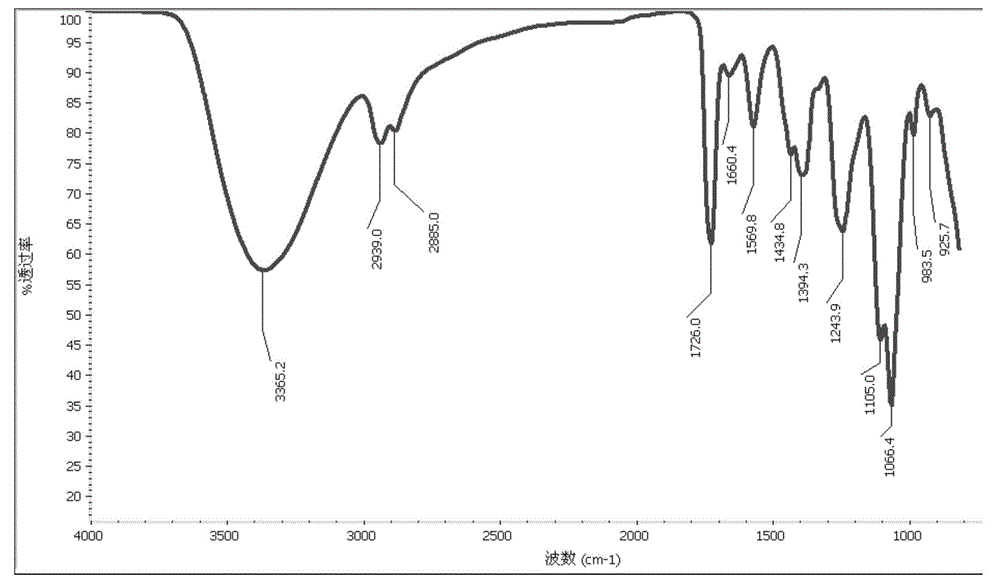

[0025] Add 149g of triethanolamine, 40g of propionic acid (the molar ratio of hydroxyl and carboxyl groups is 6:1) and 0.2g of p-toluenesulfonic acid in the reaction kettle successively, at a temperature of 110°C, using toluene as a water-carrying agent, through condensation Water separating agent and water separating agent were used to remove water, and after reacting for 5 hours, potassium hydroxide solution was added to adjust the pH value to neutral to obtain polyol amine ester A1. Infrared spectroscopic analysis was carried out on A1, as figure 1 As shown, it can be seen that there is an obvious strong peak at 1726cm-1, and the distribution is narrow, which belongs to the stretching vibration peak of the ester group, which indicates that the target group-ester group has been obtained in A1.

Embodiment 2

[0027] 191g of triisopropanolamine, 90g of oxalic acid (the molar ratio of hydroxyl and carboxyl groups is 3:1) and 3.9g of concentrated sulfuric acid are successively added into the reaction kettle. Remove water with water separator, react for 2 hours, add potassium hydroxide solution to adjust pH value to neutral, and obtain polyol amine ester A2.

Embodiment 3

[0029] Add 210g of diethanolamine, 118g of succinic acid (the molar ratio of hydroxyl to carboxyl group is 2:1) and 5.4g of concentrated hydrochloric acid in the reaction kettle successively. Water was removed from the aqueous solution, and after reacting for 10 hours, ethylenediamine was added to adjust the pH value to neutral to obtain A3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com