Silane modified polycarboxylate-type water reducing agent as well as preparation method and use method thereof

A polycarboxylic acid-based, silane-modified technology, applied in the field of building materials, can solve problems such as the problem of cement adaptability, promotion and application limitation, etc., and achieve the effects of being conducive to large-scale industrial production, high water reduction rate, and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Prepare the silane-modified polycarboxylate water-reducer of the present invention according to the following steps:

[0040] (1) Preparation before polymerization: Accurately weigh 180 parts by weight of water, and prepare the following steps for use:

[0041] Configuration of Solution A: Accurately weigh 6 parts by weight of fumaric acid, 5 parts by weight of vinyl phosphate, 1 part by weight of vinyldimethoxysilane, 2.5 parts by weight of vinylethoxysilane, vinylmethyldimethyl 2 parts by weight of oxysilane and 35 parts by weight of water, stirred and mixed evenly, pumped into the head tank A, ready to add dropwise;

[0042] Configuration of solution B: Accurately weigh 0.5 parts by weight of sodium formaldehyde sulfoxylate, 0 parts by weight of trisodium phosphate, 0.8 parts by weight of sodium methylpropene sulfonate and 50 parts by weight of water, mix and stir evenly, and pump into the high level tank B, ready to add;

[0043] Configuration of mixture C: Accura...

Embodiment 2~5

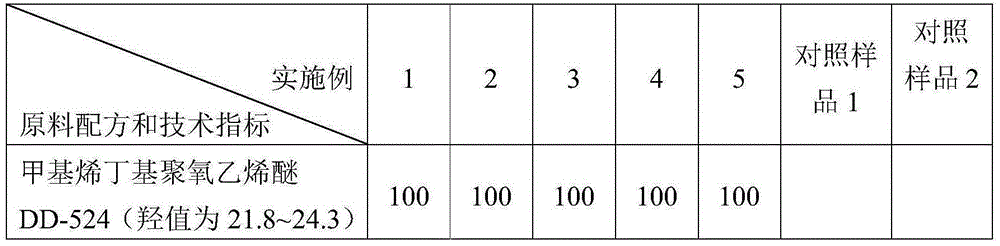

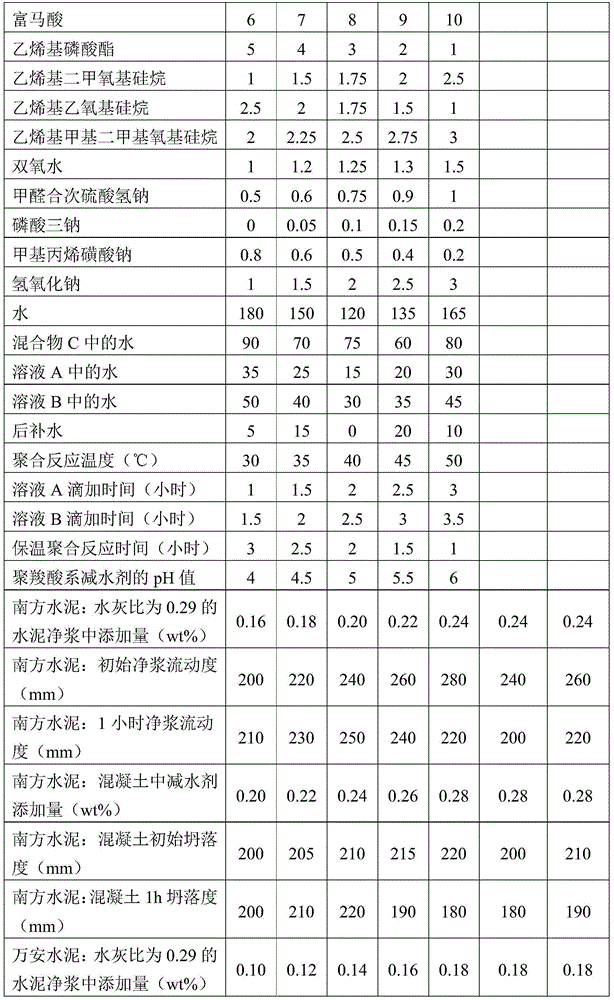

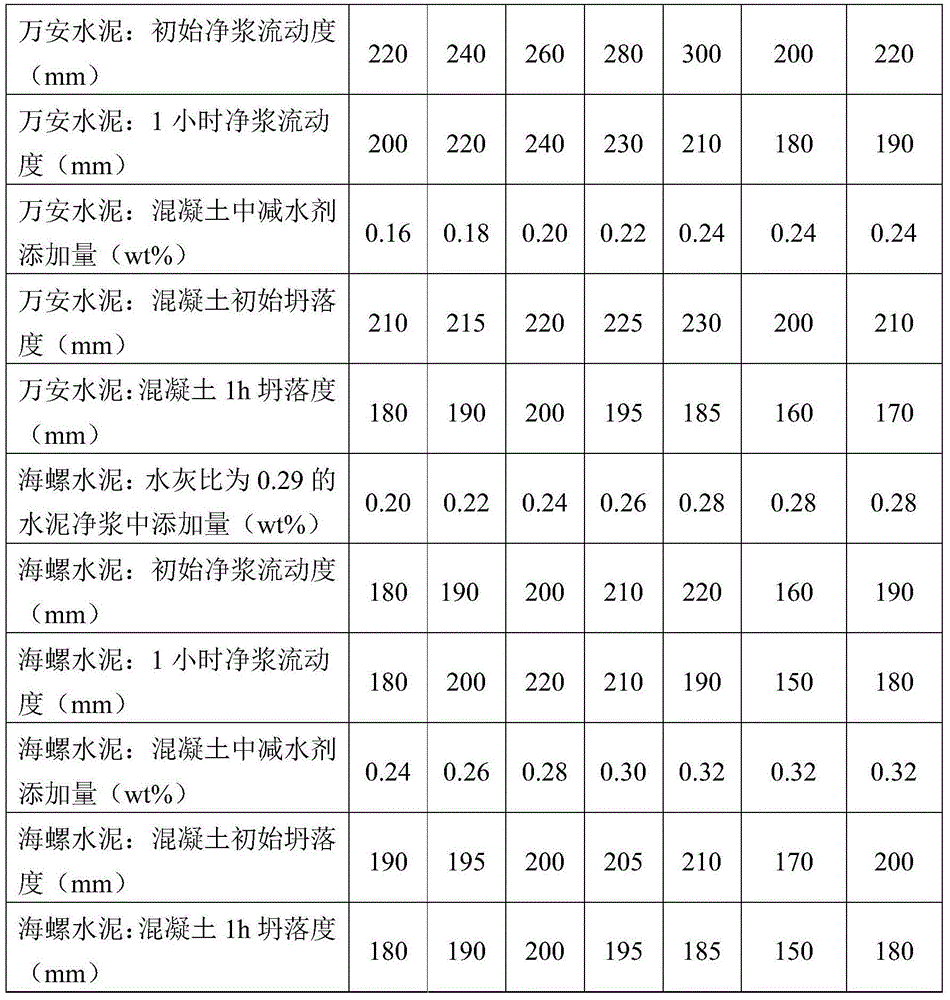

[0050] According to the method and steps of Example 1, prepare the silane-modified polycarboxylate water reducer of the present invention according to the raw material formula and operating parameters in Table 1, and prepare the obtained silane-modified polycarboxylate water reducer according to the addition amount shown in Table 1. The carboxylic acid-based water reducer was added to the cement paste and concrete, and the performance data of the obtained cement paste and concrete are shown in Table 1.

[0051] The raw material formulations and technical indicators of Examples 1-5 are detailed in Table 1 below.

[0052] Table 1 (the numerical values of each raw material component are parts by weight)

[0053]

[0054]

[0055]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com