Cationic surfactant for micro-foam drilling fluid and preparation method thereof

A surfactant and cationic technology, which is applied in the field of oilfield drilling fluid treatment agent synthesis, can solve the problems of increased drilling fluid bottom hole density, insufficient microbubble anti-compression ability, and affecting drilling safety, etc., to achieve foaming effect Good, reducing downhole complexity and strong compression resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

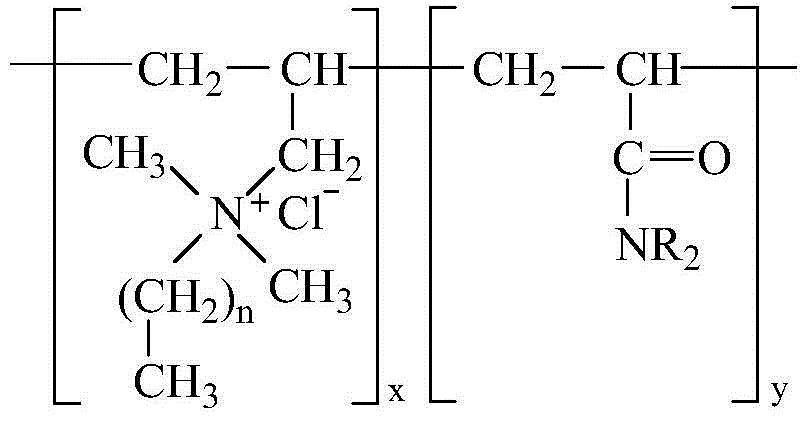

[0020] Dissolve 10g of acrylamide in 60g of clear water for later use, dissolve 0.6g of ammonium persulfate in 60g of clear water for later use, dissolve 50g of nonyldimethylallyl ammonium chloride and 0.2g of hydroquinone in 120g of clear water and raise the temperature to 55°C, then add the acrylamide solution and the ammonium persulfate solution into the reaction system together, raise the temperature of the system to 90°C and react for 1 hour to obtain a surfactant for microfoam drilling fluid with an average molecular weight of 4000 and a solid phase content of 20%. The structural formula is:

[0021]

[0022] The amount ratio of x:y substance is 2.0:1.4.

Embodiment 2

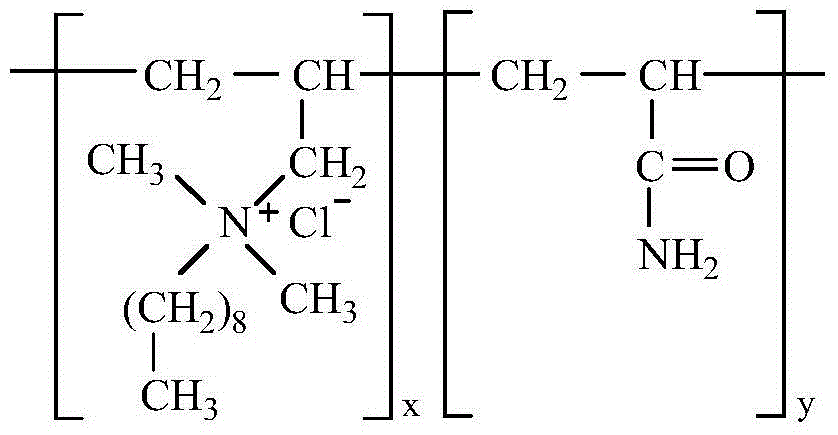

[0024] Dissolve 5g of N,N-dimethylacrylamide in 60g of clear water for later use, dissolve 1.1g of ammonium persulfate in 60g of clear water for later use, dissolve 50g of dodecyldimethylallyl ammonium chloride and 0.18g of iso Dissolve propanol in 375g of water and raise the temperature to 40°C, then add the N,N-dimethylacrylamide solution and ammonium persulfate solution into the reaction system, raise the temperature to 95°C for 2 hours, and obtain an average molecular weight of 1500 solids. A surfactant for microfoam drilling fluid with a phase content of 10%, its structural formula is:

[0025]

[0026] The amount ratio of x:y substance is 3.5:1.0.

Embodiment 3

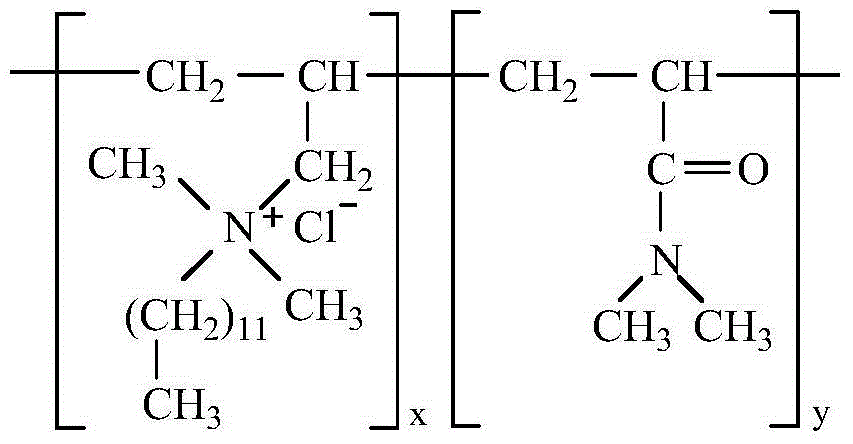

[0028] Dissolve 20g of N,N-diethylacrylamide in 40g of clear water for later use; dissolve 0.14g of ammonium persulfate in 10g of clear water for later use; Dissolve iron oxide in 80g of water and raise the temperature to 60°C, then add N,N-dimethylacrylamide solution and ammonium persulfate solution into the reaction system, raise the temperature of the system to 100°C for 1.5h, and obtain an average molecular weight of 1000 Surfactant for microfoam drilling fluid with 35% solid phase content, its structural formula is:

[0029]

[0030] The amount ratio of x:y substance is 2.9:3.1.

[0031] Embodiment 4~7 steps are identical with embodiment 1, and reaction substance and consumption thereof are as shown in table 1:

[0032] Table 1 Reaction substances and dosage table

[0033]

[0034] The cationic surfactants synthesized in Examples 1-9 were evaluated for performance.

[0035] (1) Foaming ability and foam stability

[0036] Add 1.0g of surfactant to 100mL of water,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com