Method for producing biodiesel by efficiently utilizing corncob residues via Rhodococcus

A technology of biodiesel and Rhodococcus, applied in the direction of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve problems such as limited land utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0007] Seed medium: glucose 10g / L, yeast extract 5g / L, malt extract 10g / L, Na 2 HPO 4 12H 2 O 9g / L, KH 2 PO 4 1.5g / L. Except for glucose, other components of the medium were sterilized at 121°C for 20 minutes, and glucose was sterilized at 115°C for 20 minutes alone. The inoculum size was 2%, the initial pH was 7.2±0.02, 28°C, 200rpm, and cultivated for 24h.

[0008] OD measured after 24h 600 was 47.2.

Embodiment 2

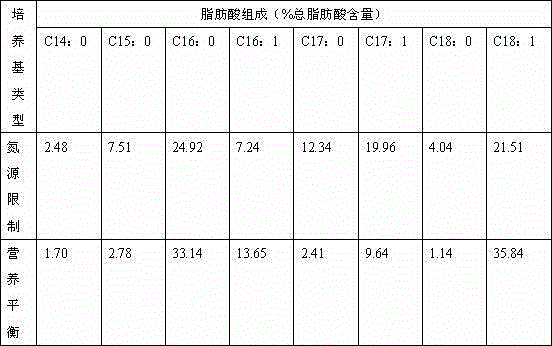

[0010] Change the amount of nitrogen source in the culture medium, transfer the bacteria in the seed culture tank in the above-mentioned embodiment 1 to the culture medium below to expand the culture respectively.

[0011] Nutritional balance medium: xylose residue 80g / L, urea 10g / L, MgSO 4 ·7H 2 O 1g / L, CaCl 2 2H 2 O 0.02g / L, FeSO 4 ·7H 2 O 0.5g / L, ZnSO 4 ·7H 2 O 0.4g / L, MnSO 4 ·5H 2 O 0.02g / L, H 3 BO 3 0.015g / L, NiCl 2 2H 2 O 0.01g / L, EDTA 0.25g / L, CoCl 2 ·6H 2 O 0.05g / L, CuCl 2 2H 2 O 0.005g / L, Stock A solution 1ml / L, 1.0M phosphate buffer solution 35.2ml / L.

[0012] Nitrogen-limited medium: xylose residue 80g / L, urea 0.636g / L, and other ingredients consistent with the nutrient-balanced medium.

[0013] Stock A solution formula: NaMoO 4 2H 2 O 2g / L, FeNa·EDTA 5g / L.

[0014] 1.0M Phosphate Buffer Solution Formula: KH 2 PO 4 47g / L, K 2 HPO 4 113g / L.

[0015] The seed solution fermented in Example 1 was transferred into a nutrient-balanced medium a...

Embodiment 3

[0016] Embodiment 3: Determination of rhodococcus cell oil production rate

[0017] A. Determination of dry weight of Rhodococcus cells

[0018] After the fermentation in Example 2 above, 1ml of fermentation broth was taken from two fermenters, centrifuged at 10,000rpm for 10min, the biomass precipitate was washed twice with water, and dried at a constant temperature at 40°C for 24h, and the biomass was determined by gravimetric analysis.

[0019] B. Extraction of oil from Rhodococcus cloudy cells (extraction method of Folch oil)

[0020] The Rhodococcus biomass produced by fermentation in the above example was homogenized with 20 volumes of chloroform:methanol (2:1) mixture. After dispersion, the entire mixture was stirred overnight on an orbital shaker at room temperature, centrifuged and the liquid phase recovered. The solvent was washed with 0.2 volumes of water. After vortexing for a few seconds, the two phases were separated by centrifugation at 2000 rpm. The upper p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com