Ni coated SiC compound powder enhanced iron-based composite material, and preparation method thereof

A technology of iron-based composite materials and composite powders, applied in transportation and packaging, metal processing equipment, coatings, etc., can solve the problems of unsatisfactory mechanical properties, poor compatibility between SiC and iron matrix, etc., and achieve improvement Interfacial bonding and dispersion uniformity, improving interfacial bonding, and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

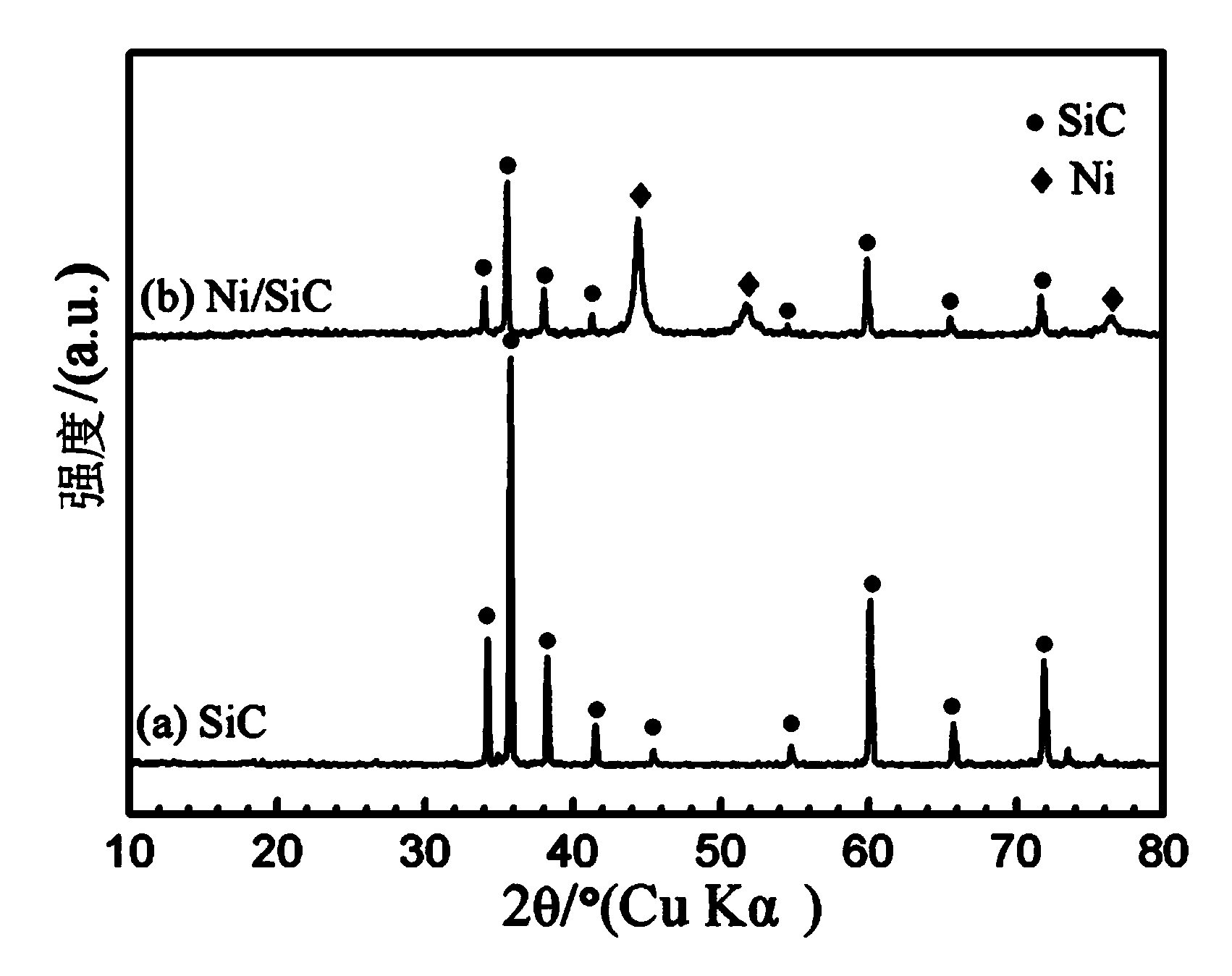

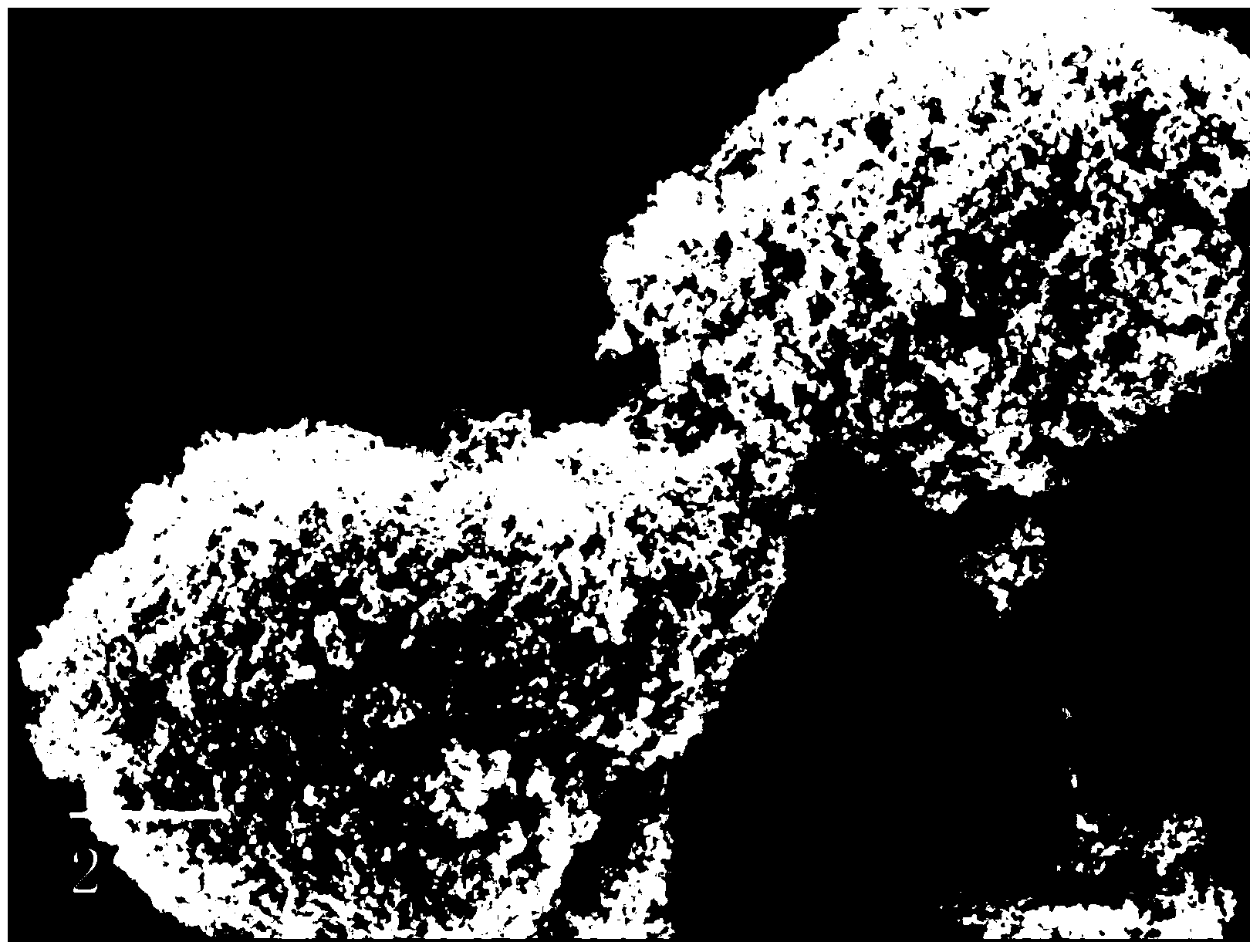

[0034] The Ni-wrapped SiC composite powder reinforced iron-based composite material in this embodiment contains the following components in weight percentage: 10% Ni-wrapped SiC composite powder and 90% iron. In the Ni-wrapped SiC composite powder, the mass ratio of Ni to SiC is 1:1.

[0035] The Ni-wrapped SiC composite powder is prepared by the following method:

[0036] 1) Add 7.5ml of N 2 h 4 ·H 2 O was added dropwise to NiCl 2 In the dehydrated ethanol solution, keep stirring for 1h to make it mix uniformly, and obtain the nickel-hydrazine complex precursor; in the nickel-hydrazine complex precursor, Ni 2+ The concentration is 0.3mol / L; N 2 h 4 ·H 2 The amount of O added is such that N 2 h 4 with you 2+ The molar ratio is 4:1;

[0037] 2) Add 1.76g of SiC powder into the NaOH solution, stir to mix evenly, and obtain a mixed slurry;

[0038] 3) Mix the nickel-hydrazine complex precursor obtained in step 1) with the mixed slurry obtained in step 2) according to ...

Embodiment 2

[0046] The Ni-wrapped SiC composite powder reinforced iron-based composite material in this embodiment contains the following components in weight percentage: 18% Ni-wrapped SiC composite powder and 82% iron. In the Ni-wrapped SiC composite powder, the mass ratio of Ni to SiC is 1:1.

[0047] The Ni-wrapped SiC composite powder is prepared by the following method:

[0048] 1) Set N 2 h 4 ·H 2 O was added dropwise to NiCl 2 In the dehydrated ethanol solution, keep stirring for 1h to make it mix uniformly, and obtain the nickel-hydrazine complex precursor; in the nickel-hydrazine complex precursor, Ni 2+ The concentration is 0.2mol / L; N 2 h 4 ·H 2 The amount of O added is such that N 2 h 4 with you 2+ The molar ratio is 8:1;

[0049] 2) Add SiC powder into NaOH solution, stir to make it evenly mixed, and get mixed slurry;

[0050] 3) Mix the nickel-hydrazine complex precursor obtained in step 1) with the mixed slurry obtained in step 2) according to Ni 2+ After mixi...

Embodiment 3

[0057] The Ni-wrapped SiC composite powder reinforced iron-based composite material in this embodiment contains the following components in weight percentage: 4% Ni-wrapped SiC composite powder, 96% iron. In the Ni-wrapped SiC composite powder, the mass ratio of Ni to SiC is 1:1.

[0058] The Ni-wrapped SiC composite powder is prepared by the following method:

[0059] 1) Set N 2 h 4 ·H 2 O was added dropwise to NiCl 2 In the dehydrated ethanol solution, keep stirring for 1h to make it mix uniformly, and obtain the nickel-hydrazine complex precursor; in the nickel-hydrazine complex precursor, Ni 2+ The concentration is 0.5mol / L; N 2 h 4 ·H 2 The amount of O added is such that N 2 h 4 with you 2+ The molar ratio is 6:1;

[0060] 2) Add SiC powder into NaOH solution, stir to make it evenly mixed, and get mixed slurry;

[0061] 3) Mix the nickel-hydrazine complex precursor obtained in step 1) with the mixed slurry obtained in step 2) according to Ni 2+ After mixing w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com