Mold core with copied natural biological super-hydrophobic surface as well as preparation method and application of mold core

A super-hydrophobic surface, super-hydrophobic technology, applied in the electrolysis process, electroforming and other directions, to achieve the effect of good biomimetic hydrophobicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

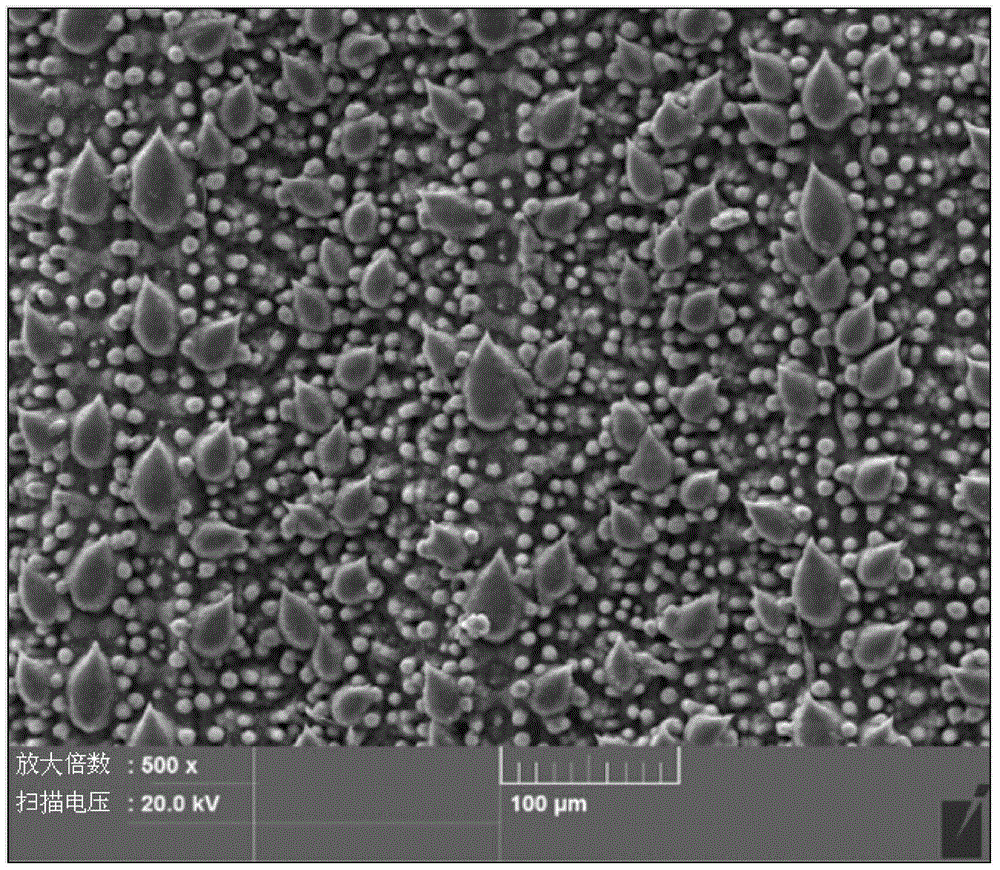

[0027] A kind of preparation method of the mold core of bamboo leaf superhydrophobic surface, comprises the steps:

[0028] (1) Extract fresh bamboo leaves, rinse them with distilled water, dry them, cut them into small pieces of 10mm×10mm and place them in a vacuum coating machine, carry out surface gold spraying treatment on the superhydrophobic surface of bamboo leaves, and the thickness of the gold spray layer is 15nm;

[0029] (2) Prepare electroforming solution: dissolve nickel sulfamate, nickel chloride, boric acid, and sodium lauryl sulfate in distilled water respectively, and stir evenly to obtain electroforming solution; each component in the described electroforming solution Concentrations are nickel sulfamate 400g / L, nickel chloride 10g / L, boric acid 30g / L and sodium lauryl sulfate 2ml / L;

[0030] (3) Add sodium lauryl sulfate dropwise to the bamboo leaves after the gold spraying treatment until the surface is completely infiltrated, and then clamp it to the electr...

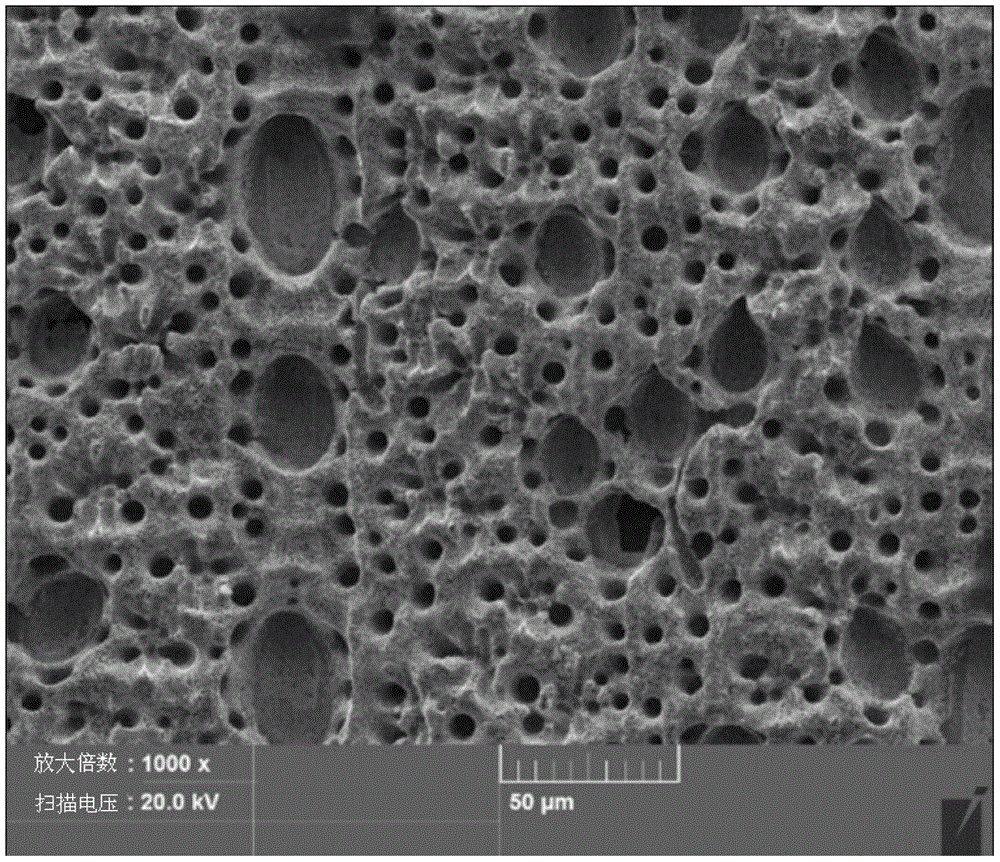

Embodiment 2

[0034] The method for replicating the super-hydrophobic surface of bamboo leaves using the mold core of the bamboo leaf super-hydrophobic surface of embodiment 1 comprises the following steps: the mold core of the super-hydrophobic surface of bamboo leaves is carried out by wire cutting, and the electroforming edge effect is removed. The corner is made into a 10mm×10mm injection mold core, the injection mold core is installed on the injection mold, and then the mold is installed on the injection molding machine for injection molding to obtain a superhydrophobic polymer part consistent with the bamboo leaf superhydrophobic surface structure. Hydrophobic testing was carried out on the obtained superhydrophobic polymer parts. The contact angle of water droplets on it was 150°, and the rolling angle was 2°, which showed good biomimetic hydrophobicity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com