Cryptomeria fortunei three-layer solid wood composite floor and preparation method thereof

A technology for solid wood composite flooring and cedar, which is applied to floors, buildings, building structures, etc., can solve the problems of poor overall economic benefits, high price and long growth cycle of pine wood, etc., and achieves low preparation costs and improved surface. The effect of wear resistance and low raw material price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

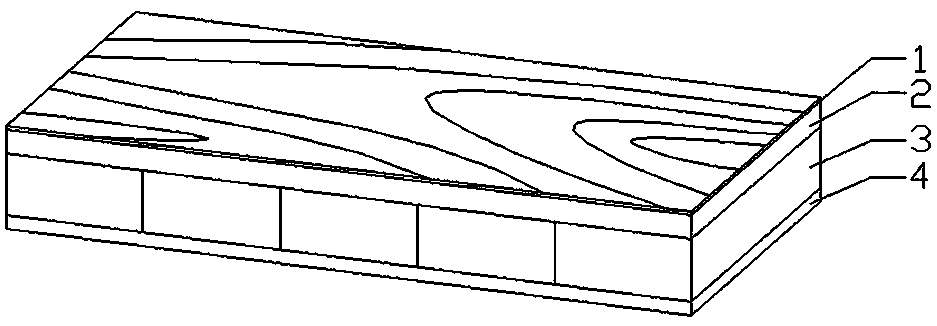

[0023] A cedar three-layer solid wood composite floor, which is composed of a wear-resistant primer layer 1, a surface board 2, a core board 3 and a bottom board 4 from top to bottom,

[0024] The wear-resistant primer layer 1 has a thickness of 5-200 μm;

[0025] The said surface plate 2 is sawed cedar into a thin plate with a thickness of 3.2-4mm;

[0026] The core board 3 is sawing the cedar into boards, planing and sawing to cut into cedar slats with a width of 25-50 mm and a thickness of 8-9 mm, and side-assembling the cedar slats as the core board;

[0027] Described base plate 4 is that poplar wood is rotary-cut veneer, and its thickness is 2mm.

Embodiment 2

[0029] 1. Raw material preparation: the surface board is made of sawn cedar thin board with a moisture content of 10-12%, and the thickness is 3.2-4mm. The core board is made of cedar lath, with a thickness of 8-9mm and a width of 25-50mm. At about 10-12%, the base plate is made of poplar veneer with a thickness of 2mm and a moisture content of 8-10%;

[0030] 2. Glue application: use urea-formaldehyde resin adhesive to apply glue to the surface plate and bottom plate, and the amount of glue applied is 180-220g / m 2 ;

[0031] 3. Blank assembly: assemble the surface plate, core plate and bottom plate after gluing, the gap between the cedar slats of the core plate is not more than 0.5mm, and the aging time after assembly is 0.5-1h;

[0032] 4. Hot pressing: Hot pressing process is adopted, the hot pressing pressure is 0.85-1.0MPa, the hot-pressing temperature is 95-100°C, and the hot-pressing time is 6-12 minutes;

[0033] 5. Chen Fang: Chen Fang health preservation time is 3 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com