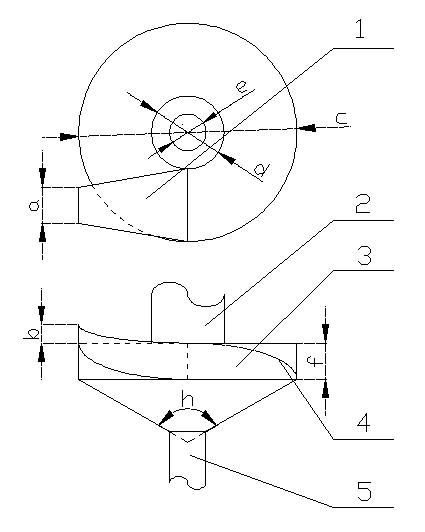

Fly ash separation and returning device for layer-burning biomass boiler

A biomass boiler and fly ash separation technology, which is applied in combustion equipment, solid fuel combustion, lighting and heating equipment, etc., can solve the problems of increasing exhaust gas temperature, damage life, burning cyclone separation device, etc., to improve boiler efficiency , to avoid the effect of burning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0019] The biomass boiler fly ash separation and return device provided by the present invention is tested on a 75t / h combined grate steam boiler, and is installed at the turning point between the third high-temperature superheater and the second high-temperature superheater. The fuel is a mixture of rice straw, rice husk and broken plywood. Among them, the rice straw is mixed with soil, and the industrial analysis results are 14.17% of total moisture, 66.33% of volatile matter, 4.57% of fixed carbon, and 14.93% of ash content. After 1 kg of rice straw is ash, it contains 22.8 grams of K element; the industrial analysis result of rice husk is Total moisture %, volatile matter 69.3%, fixed carbon 14.9%, ash content 10.8%; plywood industrial analysis results: total moisture 8.2%, volatile matter 36.7%, fixed carbon 49.3%, ash content 5.8%.

[0020] Originally, a high-temperature cyclone concentrator was installed at the turning point between the third high-temperature superheate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com