Core holding unit based on Zeiss MCT-400 CT scanning and application thereof

A core holder and holder technology, applied in the field of core holders, can solve the problems of X-ray scanning the internal core and the inability to obtain the core pore structure, etc., to achieve the effect of ensuring accuracy and accurate CT scanning results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

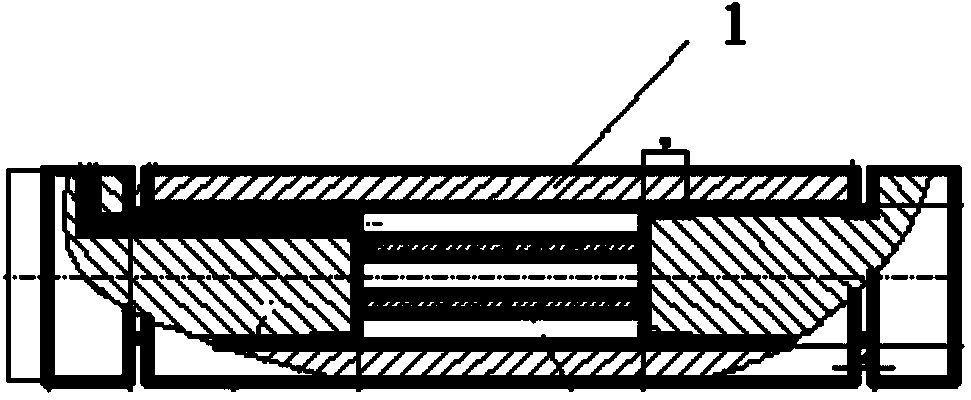

[0030] A core holder based on Zeiss MCT-400CT scanning, including a holder housing, is characterized in that the holder housing 1 is a carbon fiber tube that can withstand confining pressure.

[0031] The parameters of the carbon fiber tube are: the density is 1.26~1.34g / cm 3 , tensile strength ≥ 73MPa, Brinell hardness ≥ 10. The carbon fiber tube is a carbon fiber resin composite material, which is a commercially available material, which is polysulfone, an amorphous transparent or translucent polymer with a slight amber color, excellent mechanical properties, and has the advantages of high rigidity, wear resistance, and high strength. .

[0032] The tensile strength of the carbon fiber tube is ≥3500MPa.

[0033] The tensile elastic modulus of the carbon fiber tube is 230-430GPa.

Embodiment 2

[0035] A method for using the rock core holder as described in embodiment 1, comprising the following steps:

[0036] 1) Install the rock core in the rock core holder, keep the inlet pressure value of the rock core holder unchanged, slowly increase the confining pressure of the rock core holder, so that the net confining pressure is sequentially raised to the following pressure points: P1 , P2, P3, P4, P5, P6, P7; P1<P2<P3<P4<P5<P6<P7; the diameter of the rock core is 1cm;

[0037] 2) After each pressure point of the net confining pressure described in step 1) lasts for 30 minutes, measure the rock sample permeability according to the provisions of the People's Republic of China Petroleum and Natural Gas Industry Standards, and put it into a CT machine for fixedly performing core scanning;

[0038] 3) Slowly reduce the confining pressure to reduce the net confining pressure to the following pressure points P7, P6, P5, P4, P3, P2, and P1 in turn;

[0039] 4) After each pressur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com