Silicon block cutting device and method for removing mortar impurities

A technology of cutting device and cutting method, which is applied in fine working devices, working accessories, stone processing equipment, etc., can solve the problems of high pH and viscosity of silicon cutting mortar, low recycling rate of mortar, and easy agglomeration of silicon carbide particles, etc. To achieve the effect of improving production yield and quality, improving performance and improving recycling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

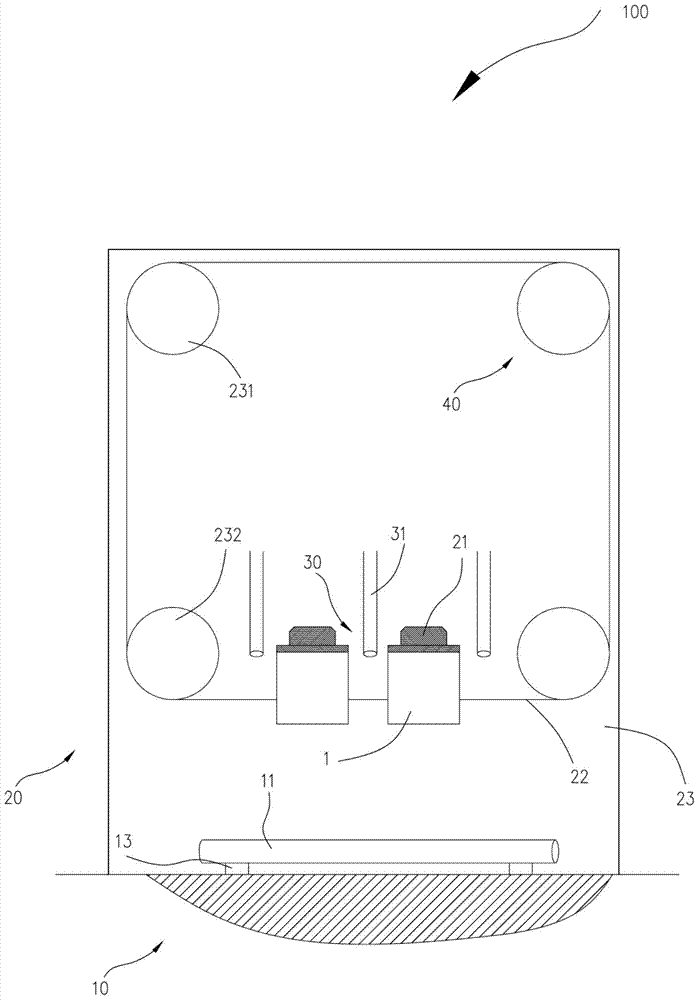

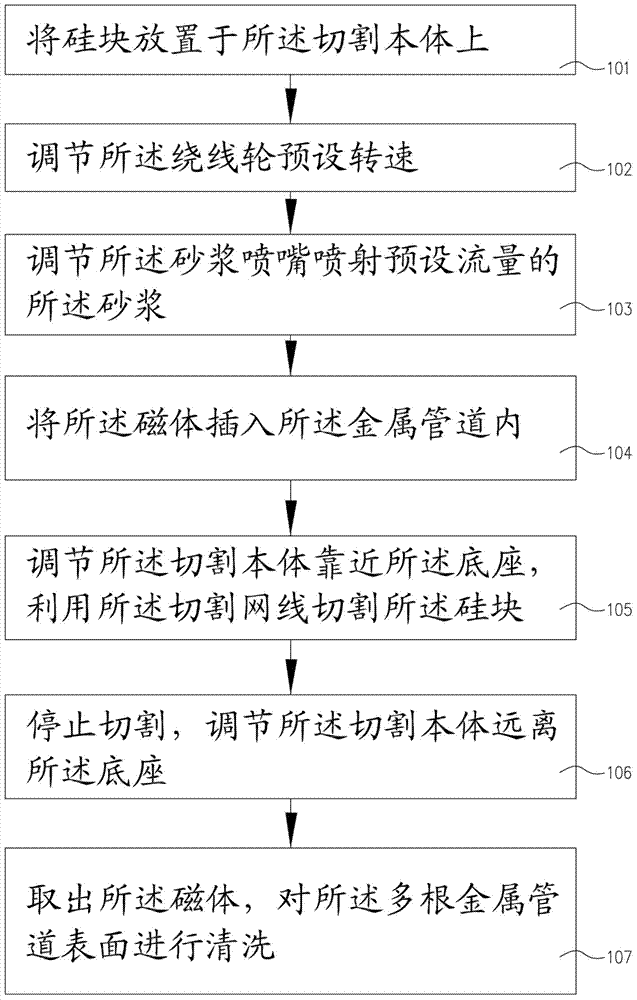

[0025] see figure 1 , the embodiment of the present invention provides a silicon block cutting device 100 for removing impurities from mortar. The silicon block cutting device 100 for removing impurities from mortar includes a base 10 , a cutting mechanism 20 and a mortar nozzle 30 . The base 10 includes a plurality of parallel hollow metal pipes 11 , and there are spaces between the multiple metal pipes 11 . Pluggable magnets 12 are arranged in the plurality of metal pipes 11 . The cutting mechanism 20 includes a cutting body 21 and a cutting wire 22. The cutting wire 22 is installed on the base 10 and corresponds to the plurality of metal pipes 11. The cutting body 21 is used for hanging silicon blocks. , the cutting body 21 is slidably disposed in a direction approaching...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com