Method for recovering surfactant and heavy metal ions in micellar-enhanced ultrafiltration (MEUF) concentrate

A technology of surfactants and heavy metal ions, applied in chemical instruments and methods, water pollutants, water/sewage treatment, etc., can solve the problems of difficult separation of mixed sediments, far less than the reuse of micelles, and destruction of micelles molecules , to achieve the effect of saving processing procedures, simple process and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

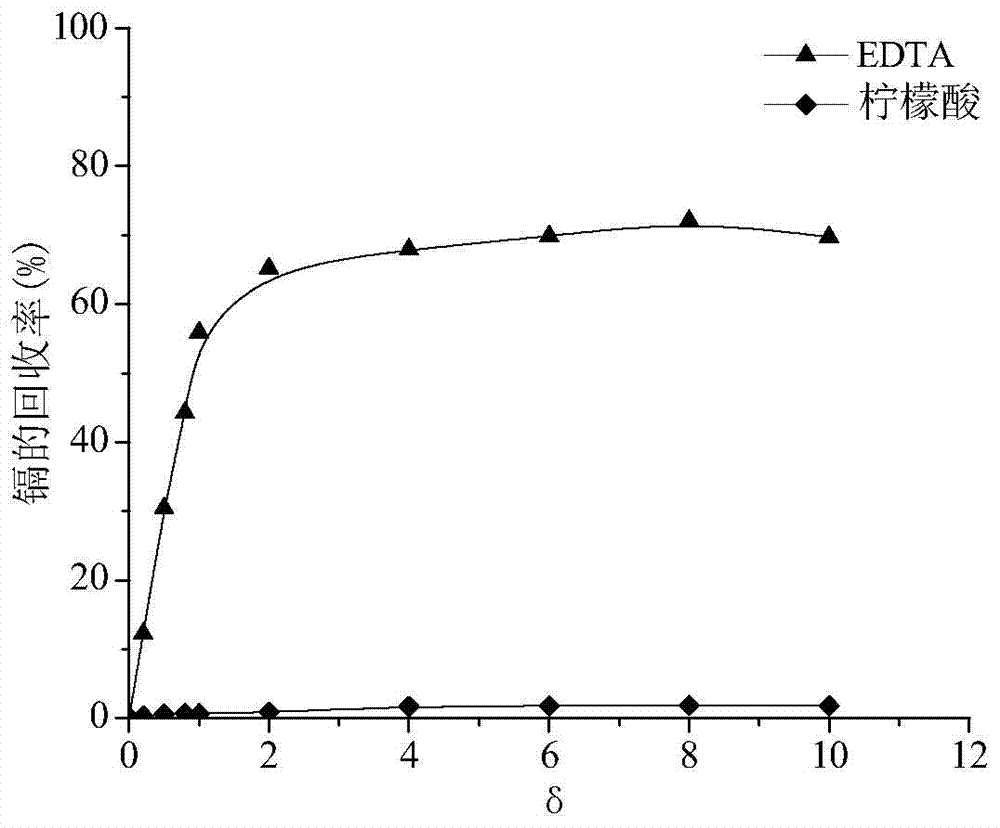

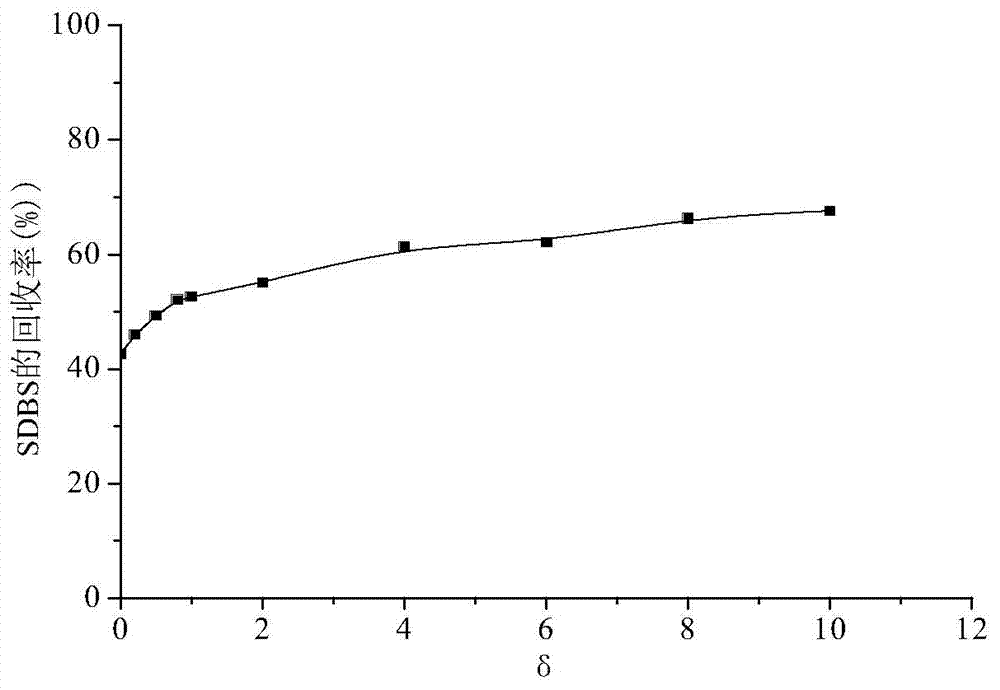

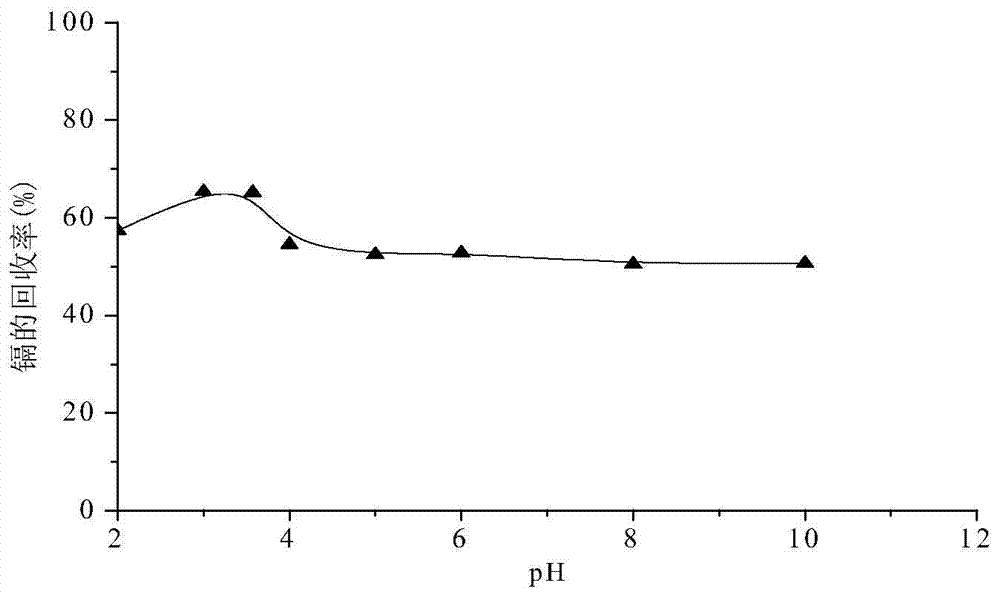

[0021] Simulate 3L concentrate wastewater to make Cd 2+ The concentration of sodium dodecylbenzenesulfonate (SDBS) is 30mg / L, and the concentration of sodium dodecylbenzenesulfonate (SDBS) is 600mg / L (1.5CMC). 2+ Adsorb on the SDBS micelles, then add a chelating agent, adjust the pH value, stir evenly and let it stand for 3 hours, then perform ultrafiltration. SDBS and CDs 2+ concentration. Among them, when the chelating agent is recovered, different amounts of ethylenediaminetetraacetic acid (EDTA) are added to make it react with Cd 2+ The molar concentration ratio δ is 0.2, 0.5, 0.8, 1, 2, 4, 6, 8, 10 respectively, and the effect of δ on SDBS and Cd 2+ The impact of recovery, select the best δ value, then configure the feed solution according to the best δ value, use 3mol / L HNO 3 Or 3mol / L NaOH solution to adjust the pH value of its feed solution to 2.5, 3, 3.5, 4, 5, 6, 8, 10, when the pH value is not controlled, it is 3.57, and the analysis of the pH value on SDBS and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com