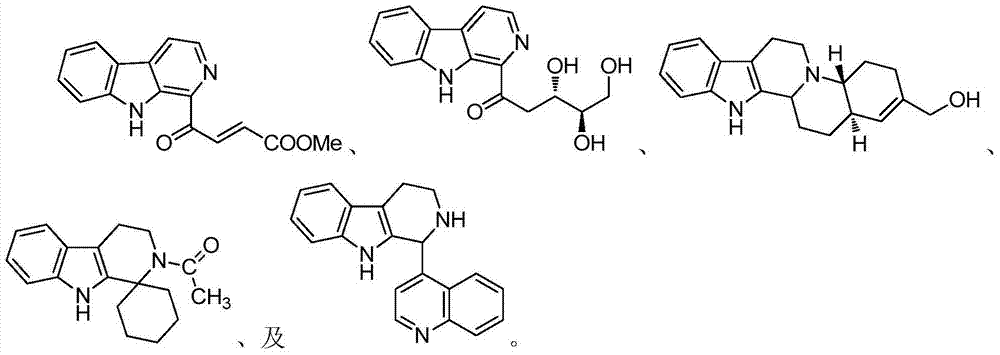

Method for rapidly and efficiently extracting carboline alkaloids

A technology of alkaloids and carbine, applied in the direction of organic chemistry, etc., can solve the problems of poor purity, poor effect and efficiency, etc., and achieve the effect of high extraction yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

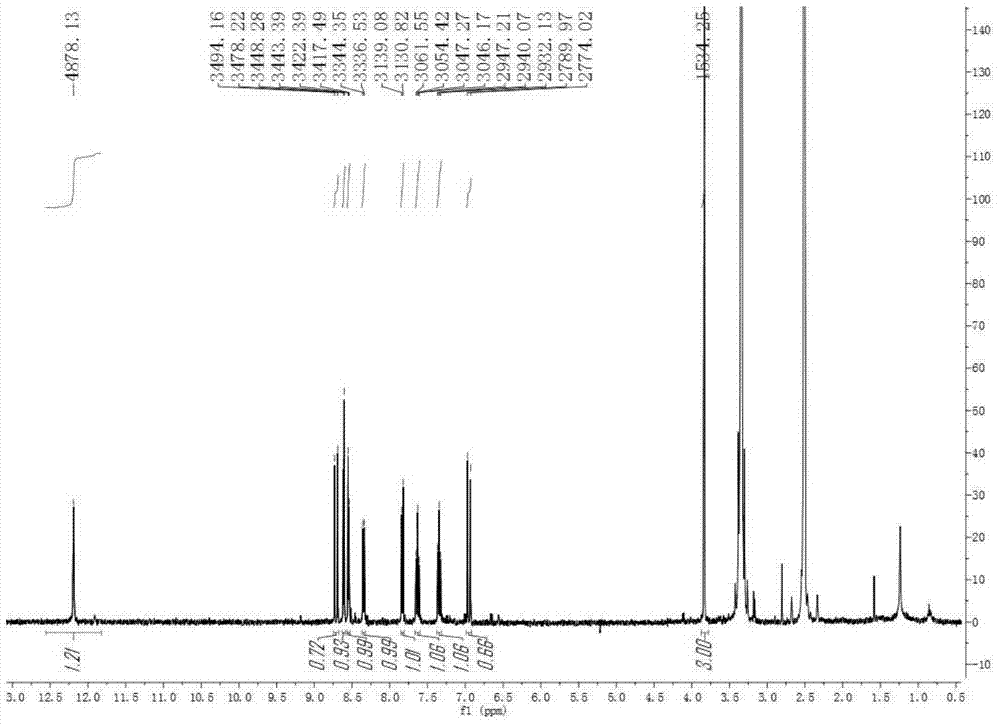

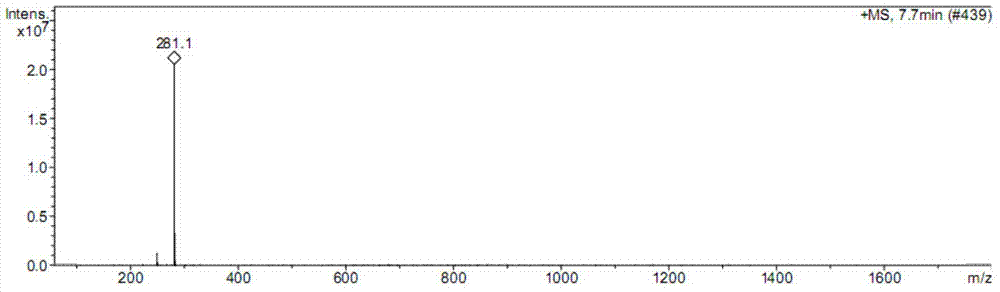

[0021] Extraction and purification of β-carbene-4-methoxy-2-ethanoic acid methyl ester:

[0022]

[0023] (1), preliminary treatment steps: 4.1 kilograms of Nitraria fruit (collected from the Qaidam Basin in Qinghai).

[0024] Soak in 25L of 95% ethanol for three days, extract by percolation at room temperature, repeat twice, combine the extracts, concentrate under reduced pressure and evaporate all the ethanol to obtain 230 g of ethanol extract. After the extract was dissolved in deionized water (about 3 L), it was sequentially extracted with petroleum ether, ethyl acetate and n-butanol (each 3 L×3). Then, the ethyl acetate and n-butanol extracts were concentrated under reduced pressure to obtain 68.3 g of ethyl acetate extract and 153.2 g of n-butanol extract respectively.

[0025] The extract obtained after the ethyl acetate extraction part was concentrated was dissolved in 150 mL of chloroform, mixed with 120 g of 100-200 mesh coarse silica gel, and the solvent was rem...

Embodiment 2

[0036] Extraction and Purification of (3S,4R)-1-β-carbene-3,4,5-trihydroxyketone

[0037]

[0038] (1), pre-treatment steps: 3.6 kilograms of Nitraria stalks (collected from the Qaidam Basin in Qinghai) were soaked in 25L 95% ethanol for three days, extracted by percolation at room temperature, repeated twice, the extracts were combined, and concentrated under reduced pressure to obtain Ethanol extract. After the extract was dissolved in deionized water (about 3 L), it was sequentially extracted with petroleum ether, ethyl acetate and n-butanol (each 3 L×3). Then, the ethyl acetate and n-butanol extracts were concentrated under reduced pressure to obtain 43.8 g of ethyl acetate extract and 103.2 g of n-butanol extract respectively. The processing step of n-butanol extract is identical with step (one) among the embodiment 1 afterwards.

[0039] (2) MCI gel CHP-20P column chromatography: after that, according to the results of TLC thin-layer chromatography tracking, the com...

Embodiment 3

[0045] Extraction and Purification of O-Acetyl Nitronine:

[0046]

[0047] (1), pre-treatment steps: 7.6 kg of Viet Nam Phyllostachys chinensis (collected from Nanning, Guangxi) was soaked in 25L 95% ethanol for three days, extracted by percolation at room temperature, and repeated twice, the extracts were combined, concentrated under reduced pressure to obtain ethanol-leached paste. After the extract was dissolved in deionized water (about 3 L), it was sequentially extracted with petroleum ether, ethyl acetate and n-butanol (each 3 L×3). Then, the ethyl acetate and n-butanol extracts were concentrated under reduced pressure respectively to obtain 83.8 g of ethyl acetate extract and 183.7 g of n-butanol extract. The processing step of ethyl acetate extractum is identical with step (one) among the embodiment 1 afterwards.

[0048] (2) MCI gel CHP-20P column chromatography: after that, according to the results of TLC thin-layer chromatography tracking, the components where...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com