Method for extracting punicalagin from pomegranate peel

A technology of punicalagin and pomegranate peel, which is applied in the field of extracting punicalagin, can solve the problems of unsuitable industrial production promotion, complex extraction method steps, cumbersome operation, etc., to increase process time and cost, increase content and extraction efficiency, The effect of high content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

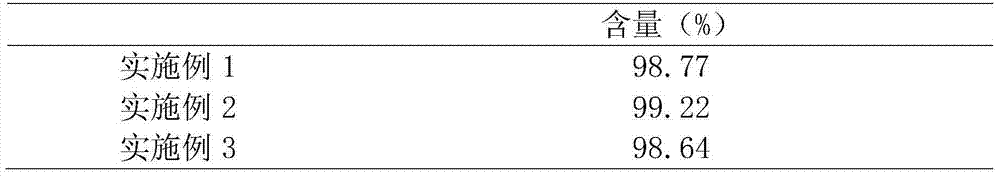

Examples

Embodiment 1

[0022] A method for extracting ellagic acid from pomegranate peel, specifically comprising the steps of:

[0023] 1) Raw material processing: pulverize 100 kg of dried pomegranate peel;

[0024] 2) High-pressure micro-jet superfine pulverization treatment: Add 800kg of pure water to the pulverized pomegranate peel, process it with a high-speed shear emulsifier for 10 minutes at a speed of 12000r / min, and then use high-pressure micro-jet superfine pulverization equipment for processing at 25°C , the treatment pressure is 100MPa, and the number of treatments is 3 times to obtain a paste slurry;

[0025] 3) High-pressure extraction: Put the paste slurry obtained in step 1) into a high-pressure tank, add purified water of the same weight, and pressurize to 4kgf / cm 2 , make the pressure uniform, and keep it for 10 minutes, return to normal pressure, and obtain the extract;

[0026] 4) Collect the extract obtained after high-pressure extraction, centrifuge, and perform D101 resin ...

Embodiment 2

[0028] A method for extracting ellagic acid from pomegranate peel, specifically comprising the steps of:

[0029] 1) Raw material processing: crush 100kg of fresh pomegranate peel;

[0030] 2) High-pressure micro-jet micro-grinding treatment: Add 1,000kg of pure water to the crushed pomegranate peel, process it with a high-speed shear emulsifier for 15 minutes at a speed of 10,000r / min, and then use high-pressure micro-jet ultra-fine pulverization equipment at 25°C Processing, the processing pressure is 80MPa, and the number of processing is 4 times to obtain a paste slurry;

[0031] 3) High-pressure extraction: Put the paste slurry obtained in step 1) into a high-pressure tank, add purified water of the same weight, and pressurize to 4kgf / cm 2 , to make the pressure uniform, and keep it for 12 minutes, return to normal pressure, and obtain the extract;

[0032] 4) Collect the extract obtained after high-pressure extraction, centrifuge, and perform D102 resin column chromato...

Embodiment 3

[0034] 1) Raw material processing: crush 100kg of fresh and dried pomegranate peels;

[0035] 2) High-pressure micro-jet superfine pulverization treatment: Add 900 kg of pure water to the crushed pomegranate peel, process it with a high-speed shear emulsifier for 20 minutes at a speed of 8000 r / min, and then use high-pressure micro-jet superfine pulverization equipment at 25 ° C. Processing, the processing pressure is 120MPa, and the number of processing is 2 times to obtain a paste slurry;

[0036] 3) High-pressure extraction: Put the paste slurry obtained in step 1) into a high-pressure tank, add purified water of the same weight, and pressurize to 4kgf / cm 2 , to make the pressure uniform, and keep it for 15 minutes, return to normal pressure, and obtain the extract;

[0037] 4) Collect the extract obtained after high-pressure extraction, centrifuge, and perform AB-8 resin column chromatography on the supernatant, then elute with 50-60% ethanol solution, concentrate and spr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com