High-performance three-proofing antibiotic fabric and finishing method thereof

A technology of antibacterial fabrics and antibacterial finishing agents, which is applied in fiber treatment, biochemical fiber treatment, and liquid-repellent fibers, etc., and can solve the problems of three-proof and anti-bacterial composite finishing liquid stability decline, three-proof and anti-bacterial properties, and complicated processes and other problems, to achieve the effect of good three defenses and antibacterial, good dispersibility, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

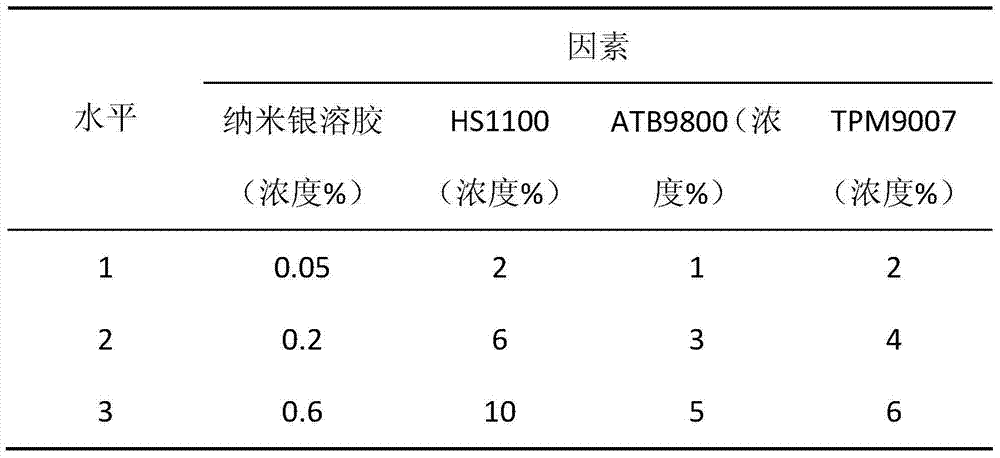

Method used

Image

Examples

Embodiment 1

[0030] The first step is the preparation of nano-silver coated with modified starch, the method is as follows:

[0031] (1) the silver nitrate solution of preparation 0.05mol / L and the sodium citrate solution that concentration is 1% are subsequent use;

[0032] (2) Add 50ml of water into the three-necked flask, then add 0.25g of modified starch, turn on the heat-collecting constant temperature heating magnetic stirrer, put the above three-necked flask into it, stir and heat up to 95°C for about 30min to gelatinize the starch;

[0033] (3) Lower the temperature to 70°C, add dropwise 10ml of the prepared silver nitrate solution into the three-necked flask, and continuously stir for 10 minutes;

[0034] (4) Add 2ml of the prepared sodium citrate solution dropwise at a rate of 1 drop / s, and stir to make it fully react;

[0035] (5) After the color of the reaction system no longer changes, that is, after the reaction is sufficient, the prepared sol is taken out from the reaction ...

Embodiment 2

[0049] The composite three-proof antibacterial finishing agent is prepared, and its preparation steps and process are the same as the first step and the second step of Example 1.

[0050] The third step gray cloth pretreatment

[0051] (1) prepare the sodium hydroxide solution that concentration is 2% by 40ml / g fabric ratio;

[0052] (2) Put the fabric into the lye and boil it for 10 minutes before taking it out;

[0053] (3) Rinse the fabric with clean water until the inspection is completed.

[0054] Step 4: Two dipping and two rolling in the same bath

[0055] (1) Padding finishing agent: take 60g / L of self-made composite three-proof antibacterial finishing agent, and adopt two dipping and two rolling processes under the conditions of padding temperature 20°C and rolling liquid rate of 80%;

[0056] (2) Drying: Dry with hot air at 110°C for 2 minutes;

[0057] (3) Baking: at 175°C, bake for 90s;

[0058] (4) Cloth output: Finally, the finished fabric is processed to pr...

Embodiment 3

[0060] The composite three-proof antibacterial finishing agent is prepared, and its preparation steps and process are the same as the first step and the second step of Example 1.

[0061] The third step gray cloth pretreatment

[0062] (1) prepare the sodium hydroxide solution that concentration is 2% by 30ml / g fabric ratio;

[0063](2) Put the fabric into the lye and boil it for 10 minutes before taking it out;

[0064] (3) Rinse the fabric with clean water until the inspection is completed.

[0065] Step 4: Two dipping and two rolling in the same bath

[0066] (1) Padding finishing agent: Take 30g / L of self-made composite three-proof antibacterial finishing agent, and adopt two dipping and two rolling processes under the conditions of padding temperature 30°C and rolling liquid rate of 75%;

[0067] (2) Drying: Dry with hot air at 120°C for 2 minutes;

[0068] (3) Baking: at 165°C, bake for 90s;

[0069] (4) Cloth output: Finally, the finished fabric is processed to pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com