Preparation method of pH-sensitive coaxial drug-loading nanometer fiber membrane

A nano-drug-loading and sensitive technology is applied in the directions of pharmaceutical formulations, fiber processing, and medical preparations with inactive ingredients, which can solve the problem of high cost and achieve the effects of low cost, good application prospects and simple process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

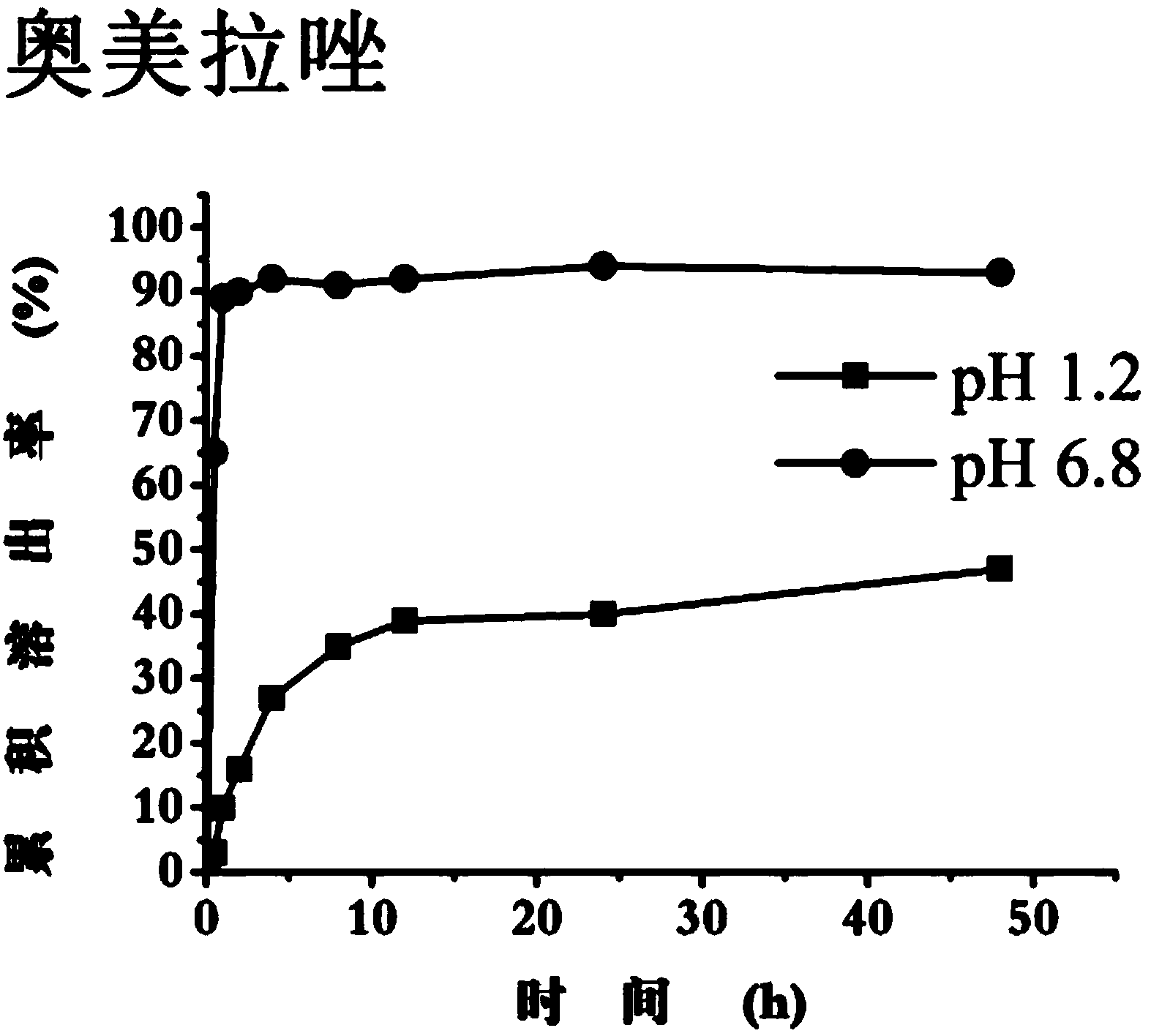

[0027] Weigh 3g of shellac, dissolve it in 5ml of ethanol solution, rotate and shake at a speed of 200rpm on a shaker at 40°C for 4 hours, and obtain a brown transparent solution as the shell solution; weigh 1g of PVA, and dissolve it In 10ml of water, stirred in a water bath at 65°C for 1 hour to obtain a transparent solution. After cooling, add 0.1 g of omeprazole, and rotate and shake at a speed of 100 rpm on a shaker at 37°C for 0.5 hours to obtain a core layer solution.

[0028] Put the prepared two spinning solutions into 5mL syringes respectively, use the coaxial spinning head as the injection tube, connect the negative electrode of the high-voltage power supply, connect the aluminum foil fiber receiving plate to the positive electrode, and adjust the syringe pump to control the amount of solution ejection. Adjust the advancing speed of the shell layer solution to 2ml / h, adjust the advancing speed of the core layer solution to 1ml / h, adjust the receiving distance to 15c...

Embodiment 2

[0030] Weigh 3g shellac, dissolve it in 5ml ethanol solution, rotate and shake at a speed of 200rpm on a shaker at 40°C for 4 hours to obtain a brown transparent shell solution; weigh another 1g PVA, dissolve it in 10ml In water, stir in a water bath at 65°C for 1 hour, take out the transparent solution, and after cooling, add 0.1 g of aspirin, rotate and shake at a speed of 100 rpm on a shaker at 37°C for 0.5 hour to obtain a core layer solution.

[0031] Add the prepared two spinning solutions into 5mL syringes respectively, use the coaxial spinning head as the injection tube, connect the negative electrode of the high-voltage power supply, connect the aluminum foil fiber receiving plate to the positive electrode, and adjust the syringe pump to control the amount of solution ejection. Adjust the advancing speed of the shell solution to 3ml / h, adjust the advancing speed of the core solution to 1.5ml / h, and adjust the receiving distance to 15cm. Then start the high voltage pow...

Embodiment 3

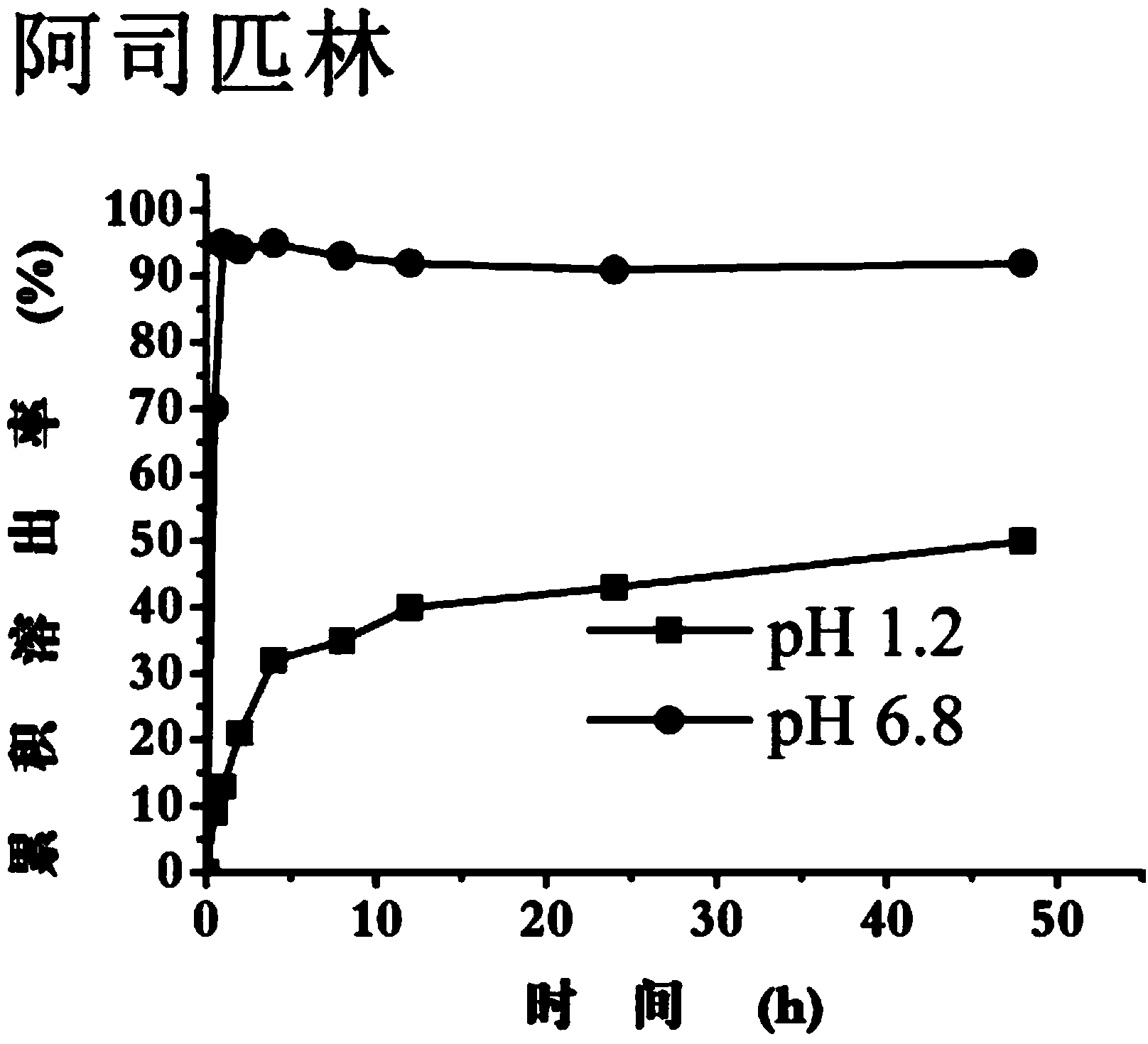

[0033] Weigh 3g shellac, dissolve it in 5ml ethanol solution, rotate and shake at a speed of 200rpm on a shaker at 40°C for 4 hours to obtain a brown transparent shell solution; weigh another 1g PVP, dissolve it in 10ml ethanol , stirred in a 65°C water bath for 1 hour. The transparent solution was taken out, after cooling, 0.1 g of ketoprofen was added, and the solution was rotated and shaken at 100 rpm on a shaker at 37° C. for 0.5 hours to obtain a core layer solution.

[0034] Inject the prepared two spinning solutions into 5mL syringes respectively, use the coaxial spinning head as the injection tube, connect the negative electrode of the high-voltage power supply, connect the aluminum foil fiber receiving plate to the positive electrode, and adjust the syringe pump to control the spray volume of the solution. Adjust the advancing speed of the shell solution to 2ml / h, adjust the advancing speed of the core solution to 1ml / h, adjust the receiving distance to 15cm, then sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com