Preparation method of modified emulsified asphalt for ultra-thin wearing layer

A technology of emulsified asphalt and wear layer, which is applied in the direction of building components, building insulation materials, buildings, etc., can solve the problems of insufficient viscosity, low elasticity and flexibility of asphalt, and low solid content, so as to improve the bonding strength and bonding performance Strong, fast demulsification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

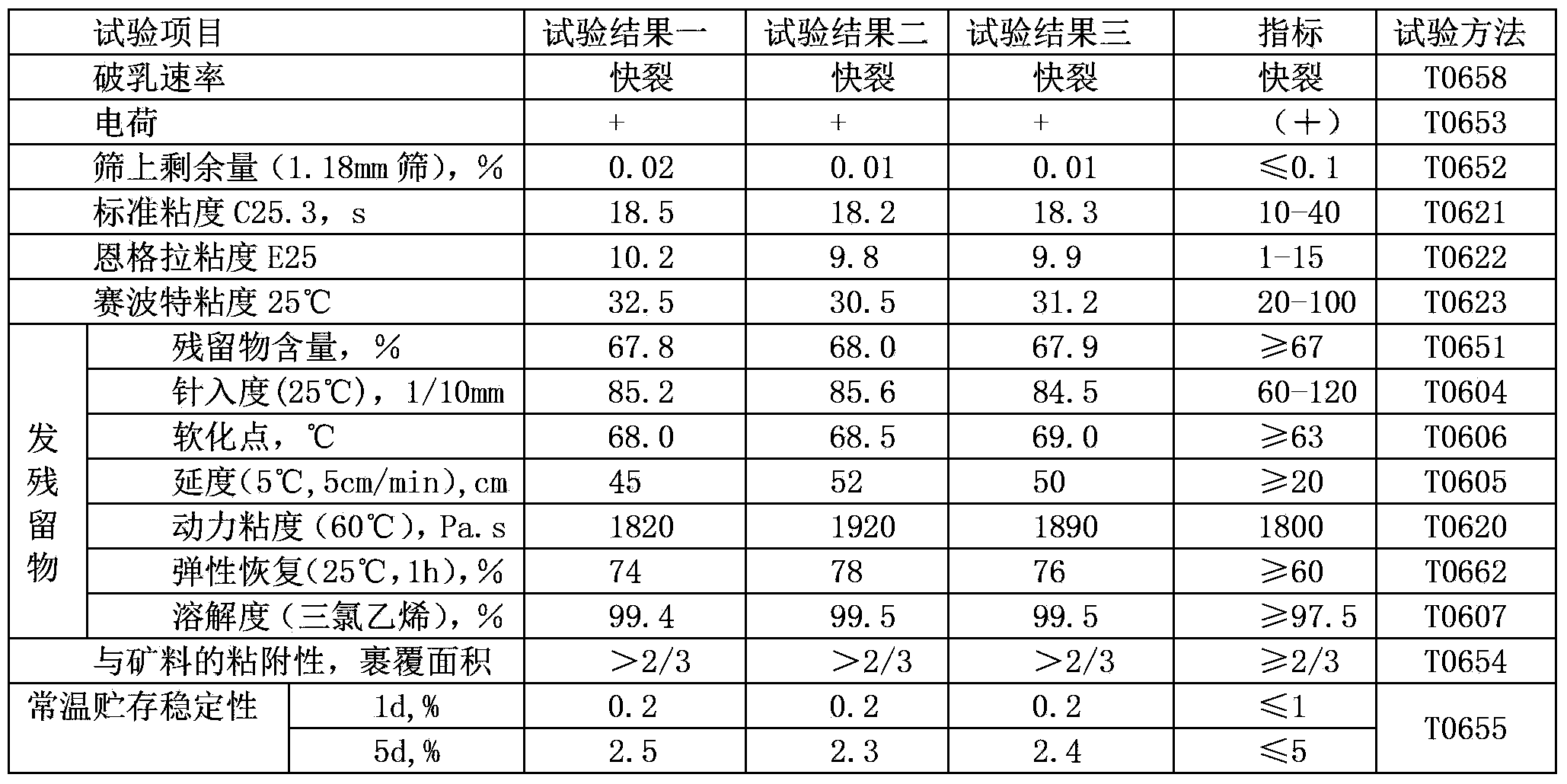

Examples

Embodiment 1

[0021] Take 10 tons of Sinopec 70# road petroleum asphalt, 360kg SBS (solid styrene-butadiene-styrene polymer thermoplastic rubber), and run it through a colloid mill with a speed of 5000rpm at high speed to control the particle size of SBS to less than 5 μm. Sexual asphalt.

[0022] Get above-mentioned modified asphalt 680kg, 6kg octadecyltrimethylammonium bromide, 1kg calcium chloride and 313kg water standby. Heat the water to 40-60°C, add octadecyltrimethylammonium bromide and calcium chloride, adjust the pH value of the soap liquid to 2.0 with 36% concentrated hydrochloric acid, and prepare the soap liquid. After heating the soap liquid to 50°C, the particles in the soap liquid are dispersed evenly by turning the colloid mill with a speed of 5000rpm at high speed, and then slowly add the modified asphalt heated to 140°C to the running colloid mill, and then Recycle operation until the emulsion is uniformly dispersed, and the obtained emulsion is the modified emulsified as...

Embodiment 2

[0025] Take 10 tons of Korean Ssangyong 70# road petroleum asphalt and 320kg of SBR (latex styrene-butadiene rubber), and run it through a colloid mill with a speed of 5000rpm at high speed to control the SBR particle size to less than 5 μm to obtain modified asphalt.

[0026] Get 670kg of the above-mentioned modified pitch, 5kg of octadecyltrimethylammonium chloride, 0.8kg of polyvinyl alcohol and 324.2kg of water for subsequent use. Heat the water to 40-60°C, add cationic emulsifier and stabilizer, adjust the pH value of the soap solution to 1.8 with 36% concentrated hydrochloric acid, and prepare the soap solution. After heating the soap liquid to 50°C, the particles in the soap liquid are dispersed evenly by rotating the colloid mill at a speed of 4000rpm, and then slowly add the modified asphalt heated to 138°C to the running colloid mill, and then Recycle operation until the emulsion is uniformly dispersed, and the obtained emulsion is the modified emulsified asphalt for...

Embodiment 3

[0029] Take 10 tons of TPC70# road petroleum asphalt, 150kgSBS, 200kgSBR, run through a colloid mill with a rotation speed of 5000rpm at high speed, control the particle size of SBS and SBR to be less than 5μm, and obtain modified asphalt.

[0030] Get above-mentioned modified asphalt 675kg, the mixture of 5.5kg dodecyltrimethylammonium bromide and cetyltrimethylammonium chloride, 1.2kg sodium carboxymethylcellulose and 318.3kg water are standby. Heat the water to 40-60°C, add cationic emulsifier and stabilizer, adjust the pH value of the soap liquid to 2.0 with 36% concentrated hydrochloric acid, and prepare the soap liquid. After heating the soap liquid to 48°C, the particles in the soap liquid are dispersed evenly by turning the colloid mill with a speed of 4000rpm at high speed, and then slowly add the modified asphalt heated to 140°C to the running colloid mill, and then Recycle operation until the emulsion is uniformly dispersed, and the obtained emulsion is the modified...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| penetration | aaaaa | aaaaa |

| penetration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com