Camellia oil dewaxing degreasing process

A technology of camellia oil and craftsmanship, which can be applied in the field of products and can solve the problems of low labor productivity and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

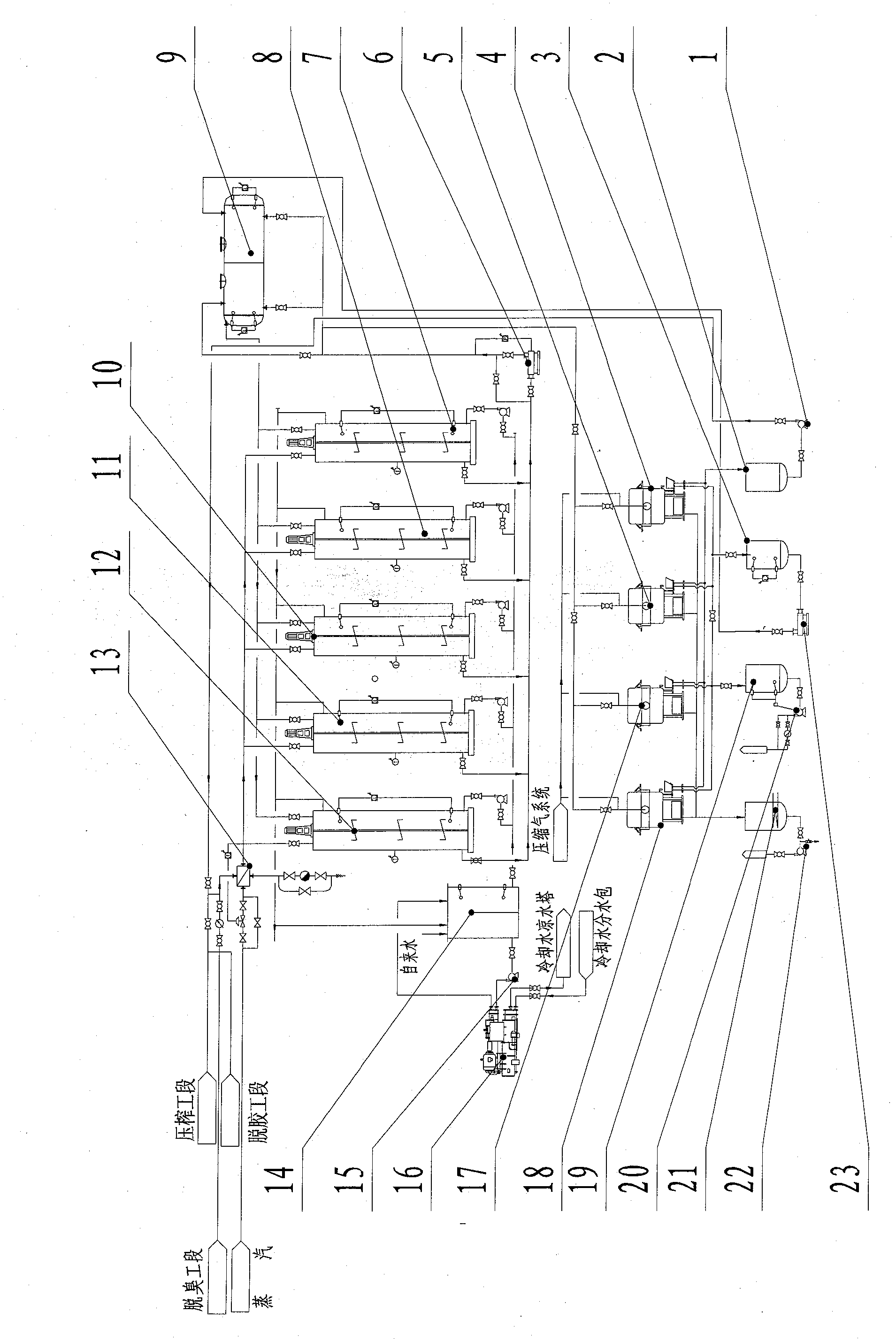

[0007] The products involved in this project, such as figure 1 As shown, the edible camellia oil delivered by the pressing process, the degumming process, and the deodorizing process is heated by steam through the heat exchanger 13 provided in the system; the crystals that are not easy to separate are melted. After the edible camellia oil is heated, it is transported to the No. 1 knot, crystal growth tank 12, No. 2 knot, crystal growth tank 11, No. 3 knot, crystal growth tank 10, No. 4 knot, crystal growth tank 8, and No. 5 according to the actual situation The junction and crystal growth tank 7 carries out crystallization and crystal growth. The refrigerant provided by the refrigerant tank 14, the refrigerant pump 15, and the refrigeration unit 16 circulates in the junction and crystal growth tanks, and the heat is continuously taken away; the edible oil reaches the crystallization and crystal growth process temperature; the heat absorbed by the refrigeration unit 16 , repla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com