Dissolved-oxygen control method based on improved differential algorithm

A technology for dissolved oxygen control and improved differential, which is applied in various fluid ratio control, self-adaptive control, general control systems, etc., and can solve problems such as inability to realize real-time online control of the production process, high operating costs, and backward automation level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

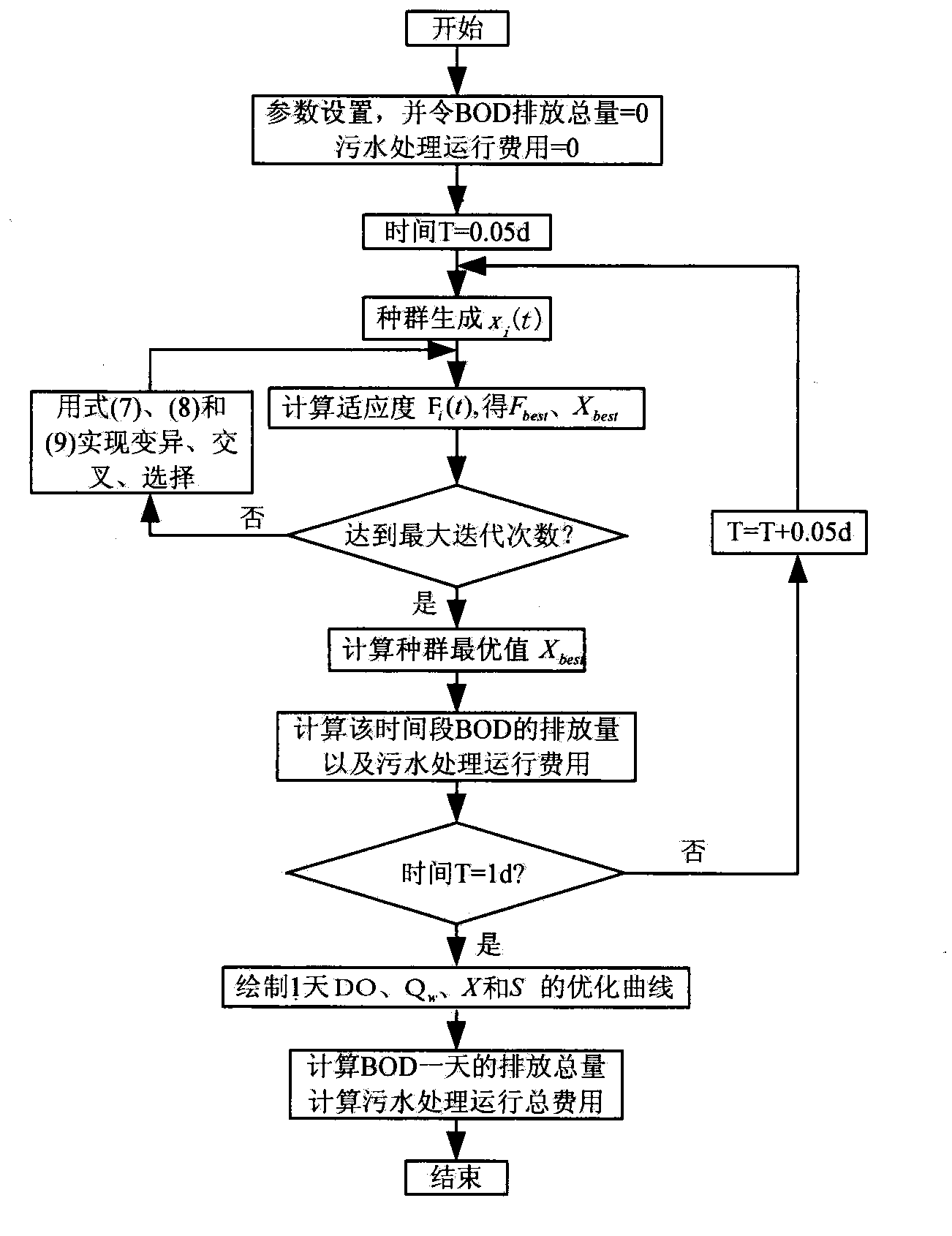

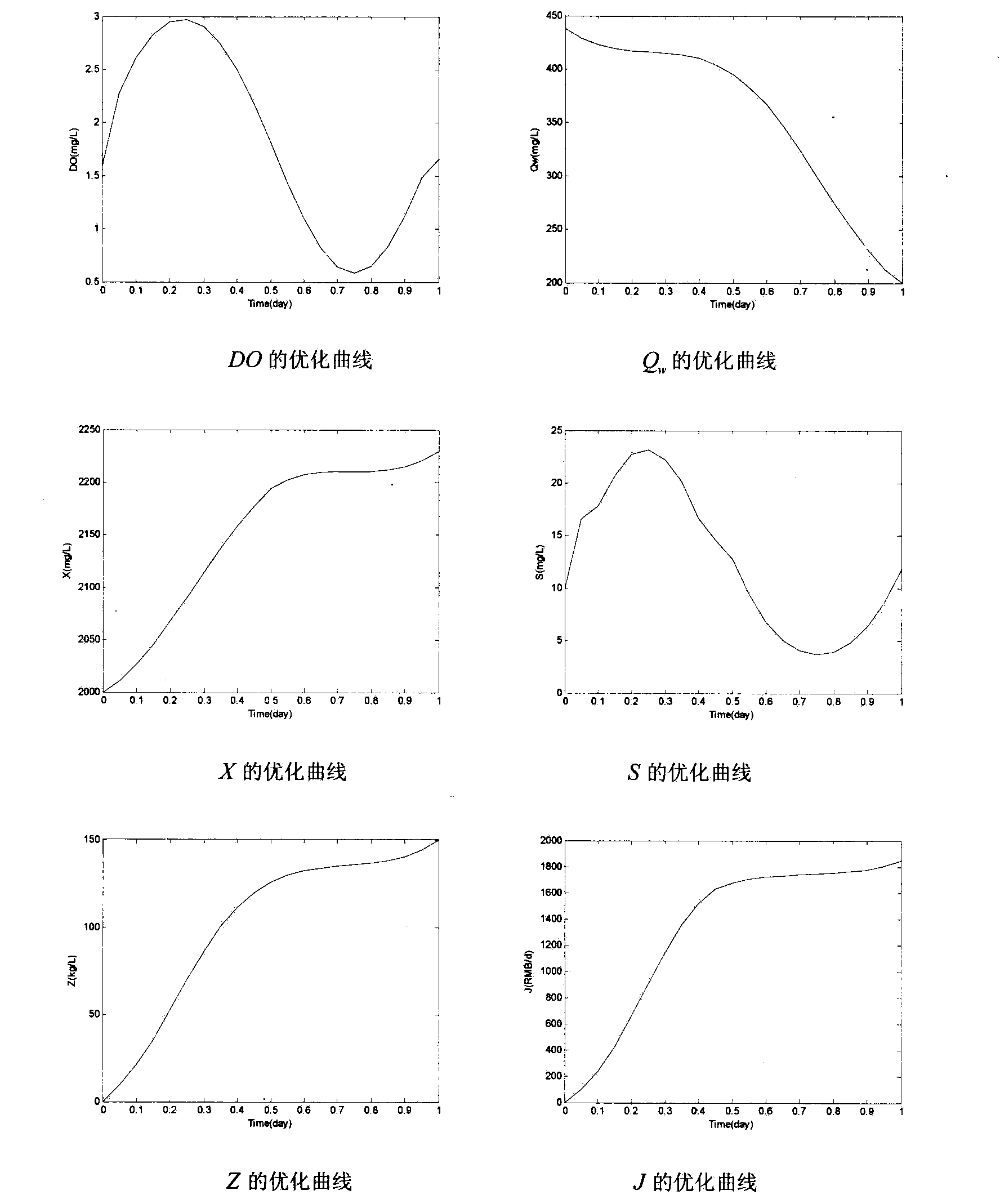

[0046] The present invention will be further described below in conjunction with accompanying drawing:

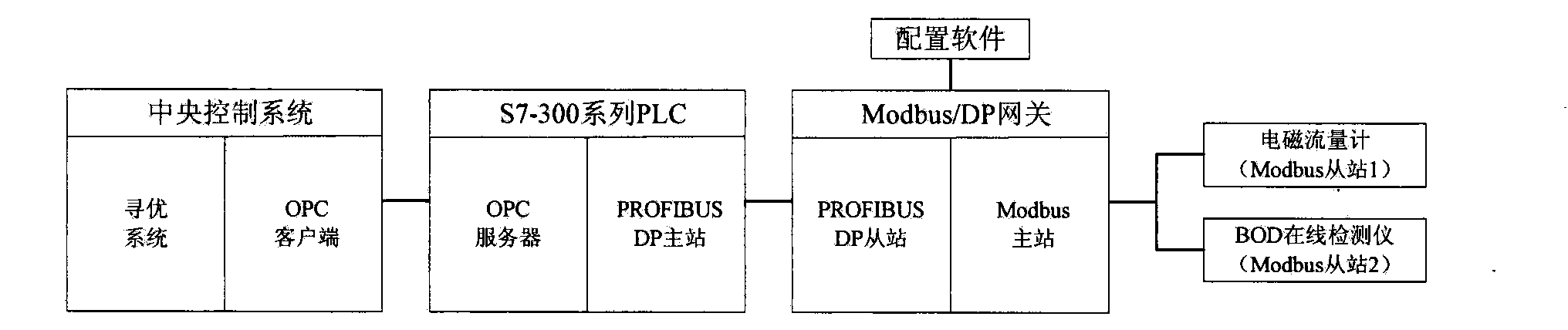

[0047] like figure 1 As shown, the present invention includes: a data acquisition system and a central control system.

[0048] The data collection system includes: sensing equipment, communication gateway, OPC server; the sensing equipment detects the technical parameters of the sewage treatment process online in real time, connects with the gateway through a communication protocol, and the gateway converts the collected data into an OPC server capable of The identified data is transmitted through the OPC server.

[0049] The sensing equipment includes: electromagnetic flowmeter and BOD online detector, real-time online detection of Q and S 0 , use the sensing device that supports the MODBUS communication protocol.

[0050] The communication gateway adopts the general-purpose serial port PROFIBUS DP gateway PM-160 of Shanghai Sibo Automation Technology Co., Ltd. to real...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com