Lithium battery cathode material and preparation method thereof

A cathode material, lithium battery technology, applied in battery electrodes, positive electrodes, active material electrodes, etc., can solve the problems that nickel-cobalt-manganese ternary materials are difficult to achieve cycle performance, thermal stability performance and electrochemical performance, and achieve high capacity. , the effect of high thermal stability and high electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

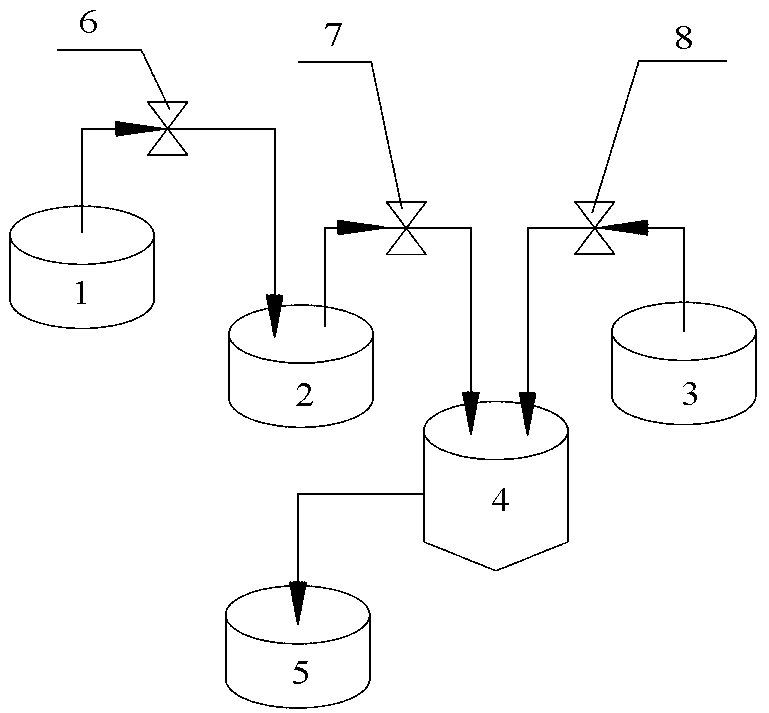

[0019] The invention provides a method for preparing a positive electrode material of a lithium battery, comprising the following steps:

[0020] S1, first pump the solution A and the alkali solution into the reaction vessel at the same speed, and carry out the co-precipitation reaction;

[0021] S2. After step S1 is carried out for 5-25 hours, pump solution B into solution A at a constant speed, and pump the whole mixed solution and alkali solution into the reaction vessel at a constant speed while pumping solution B, and continue the co-precipitation reaction. After the reaction is terminated, the precursor is obtained by drying;

[0022] S3, mixing the precursor obtained in step S2 with a lithium salt, and sintering to obtain the positive electrode material of the lithium battery;

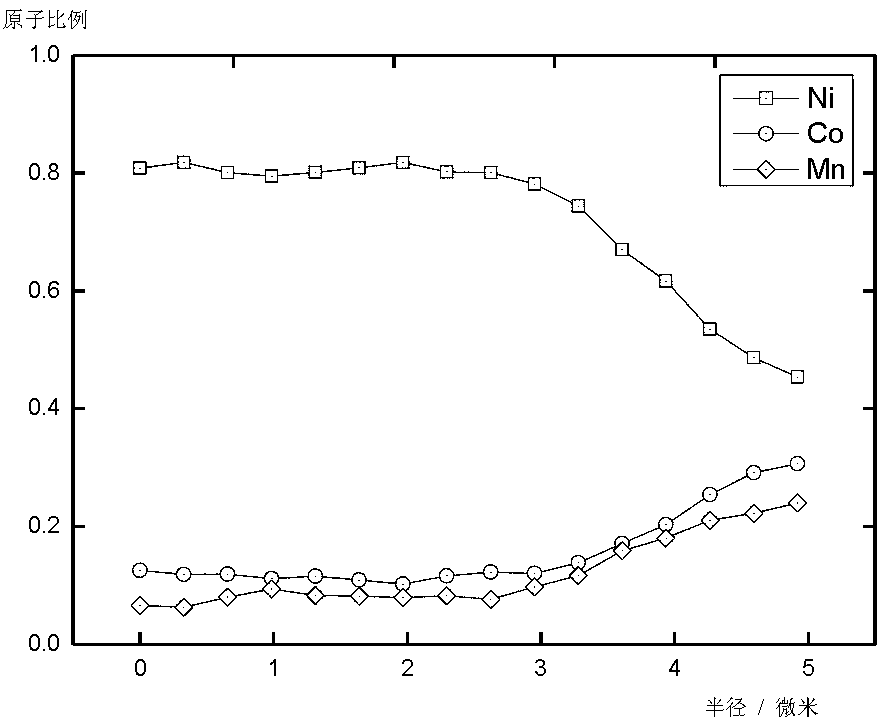

[0023] The solution A is a mixed solution containing water-soluble nickel salt, water-soluble manganese salt and water-soluble cobalt salt, wherein the molar ratio of Ni, Co, and Mn=(1-2x):x:x,...

Embodiment 1

[0047] (1) if figure 1 As shown, the solution A1 of 2mol / L is charged in the second container 2, and the solution A1 is an aqueous solution of nickel sulfate, manganese sulfate and cobalt sulfate, and the molar ratio Ni:Co:Mn=8:1:1; A container 1 is filled with 2mol / L solution B1, which is an aqueous solution of nickel sulfate, manganese sulfate and cobalt sulfate, and the molar ratio Ni:Co:Mn=4:3:3. Load alkaline solution into the third container 3, the alkaline solution is a mixed system of sodium hydroxide and ammoniacal liquor, the concentration of sodium hydroxide in the alkaline solution is 2mol / L, and the concentration of ammoniacal liquor is 1mol / L;

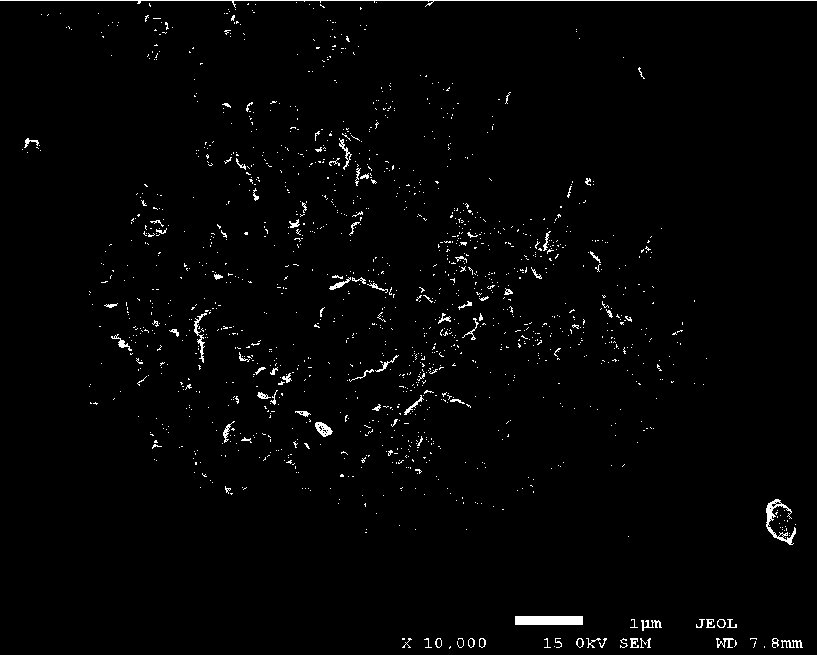

[0048] (2) Turn off the first pump 6, turn on the second pump 7 and the third pump 8, and pump the solution A1 in the second container 2 and the alkali solution in the third container 3 into the reaction container 4 at the same speed The reaction is carried out in the middle, and the reaction time is 10h; At this moment,...

Embodiment 2

[0052] The same steps as in Example 1 were used to prepare the lithium battery positive electrode material S20 of this example, except that:

[0053] In step (1), solution A2 is an aqueous solution of nickel nitrate, manganese nitrate and cobalt nitrate, the molar ratio Ni:Co:Mn=5:2.5:2.5, the concentration of solution A2 is 3mol / L; solution B2 is nickel nitrate, nitric acid The aqueous solution of manganese and cobalt nitrate, the molar ratio Ni:Co:Mn=1:4.5:4.5, the concentration of solution B2 is 0.6mol / L;

[0054] In step (2), the reaction time is 15 hours; at this time, the remaining solution A2 in the second container 2 is equal to the volume of the solution B2 contained in the first container 1;

[0055] In step (3), the reaction time is 2h.

[0056] Through the above steps, the co-precipitation precursor S2 (its chemical formula is Ni 0.50 co 0.25 mn 0.25 (OH) 2 ) and lithium battery cathode material S20 (its chemical formula is LiNi 0.50 co 0.25 mn 0.25 o 2 )....

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com