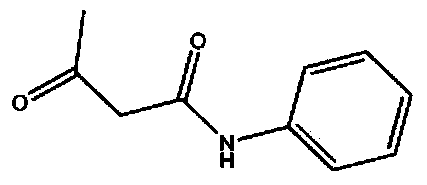

Synthesis and crystallization method of N-acetoacetanilide compound

A technology for acetoacetanilide and aniline compounds, which is applied in the field of synthesis and crystallization of N-acetoacetanilide compounds, can solve the problems of high solvent consumption, influence on application, reduced yield and the like, and achieves reduced caking phenomenon and prolonged crystallization. The effect of short block time and crystallization time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

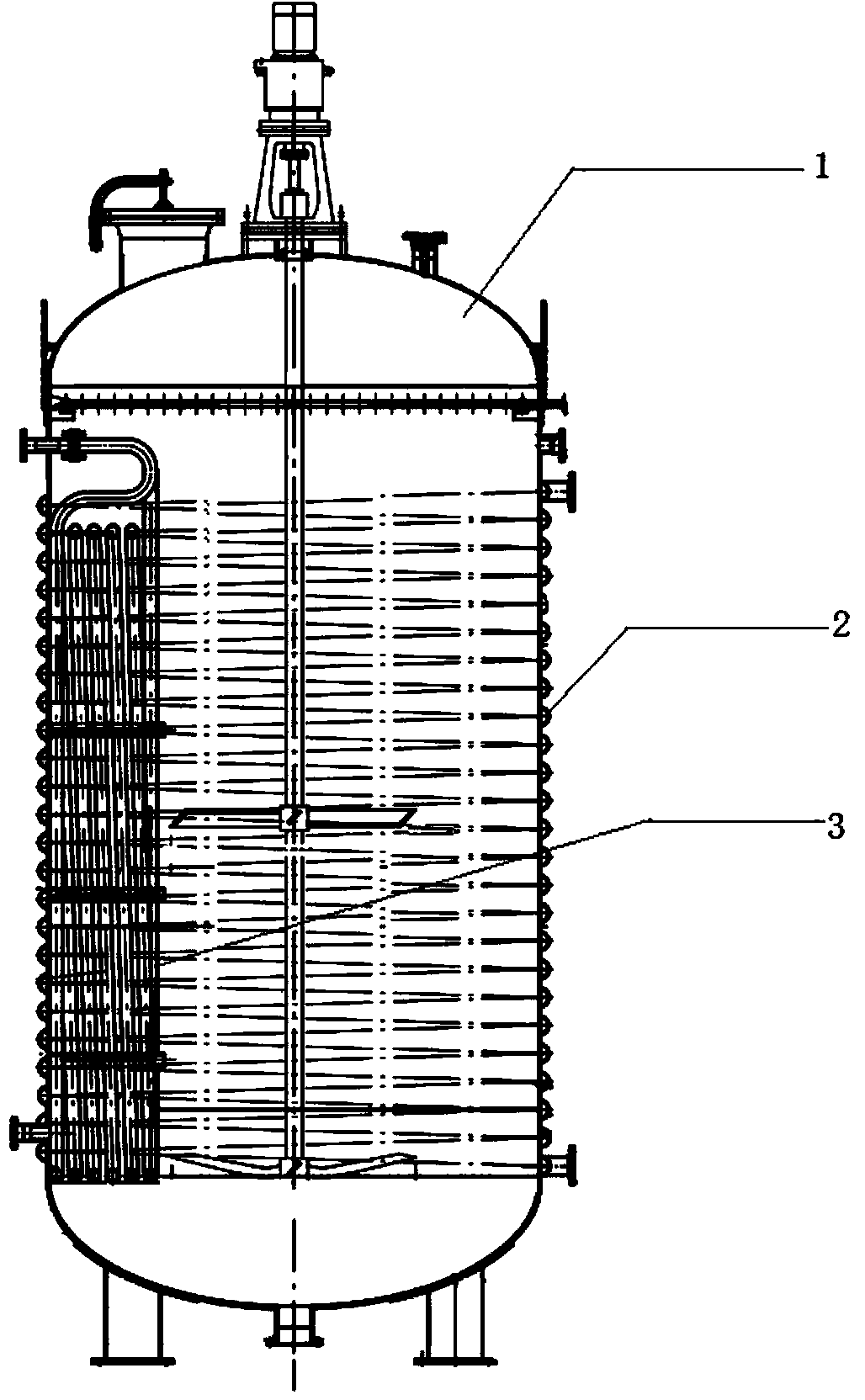

[0036] A method for the synthesis and crystallization of N-acetoacetanilide compounds. The reactor is a stainless steel reactor. The schematic diagram is as follows figure 1 As shown, the stainless steel reactor 1 is provided with a cooling tube, and the cooling tube includes an outer half tube (2) arranged outside the reactor and an inner coil 3 arranged inside the reactor.

[0037] It includes the following steps:

[0038] (1) Under anaerobic conditions, mix anilines with ethanol, and then add diketene for diacetylation to obtain acetoacetanilide compounds; the mixing temperature is 30°C, and the acetylation reaction time is 2 hours; diacetylated The reaction temperature is 30°C; after the diacetyl reaction is completed, the temperature of the heat preservation treatment is 40°C, and the heat preservation time is 3 hours;

[0039] (2 After the heat preservation is over, pass 15°C circulating water into the cooling pipe, and control the material to cool from 60°C to 40°C within 40 ...

Embodiment 2

[0044] A method for the synthesis and crystallization of N-acetoacetanilide compounds. The reactor is a stainless steel reactor. The schematic diagram is as follows figure 1 As shown, the stainless steel reactor 1 is provided with a cooling tube, and the cooling tube includes an outer half tube (2) arranged outside the reactor and an inner coil 3 arranged inside the reactor.

[0045] It includes the following steps:

[0046] (1) Under anaerobic conditions, mix anilines with ethanol, and then add diketene for diacetylation to obtain acetoacetanilide compounds; the mixing temperature is 30°C, and the acetylation reaction time is 2 hours; diacetylated The reaction temperature is 30°C; after the diacetyl reaction is completed, the temperature of the heat preservation treatment is 40°C, and the heat preservation time is 3 hours;

[0047] (2) After the heat preservation is over, pass 16°C circulating water into the cooling tube, and control the material to cool from 60°C to 40°C within 60...

Embodiment 3

[0052] A method for crystallization of N-acetoacetanilide compounds. The reactor is a stainless steel reactor. The schematic diagram is as follows figure 1 As shown, the stainless steel reactor 1 is provided with a cooling tube, and the cooling tube includes an outer half tube 2 arranged outside the reactor and an inner coil 3 arranged inside the reactor.

[0053] It includes the following steps:

[0054] (1) Under anaerobic conditions, mix 2,4-dimethylaniline with ethanol, and then add diketene for diacetylation to obtain acetoacetanilide compounds; the mixing temperature is 30°C, and the acetylation reaction time is 2 Hours; the reaction temperature of diacetylation is 30°C; after the completion of the diacetyl reaction, the temperature of the heat preservation treatment is 40°C, and the heat preservation time is 3 hours;

[0055] (2) After the heat preservation is over, pass 14°C circulating water into the cooling pipe to cool the material from 60°C to 30°C within 50 minutes; the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com