High-elastic polyvinyl chloride weather-resistant flame-retardant super-bright crystal membrane and preparation method thereof

A polyvinyl chloride and polyvinyl chloride resin technology, applied in flat products, other household appliances, applications, etc., can solve the problems that affect the use and appearance of the product, cannot achieve ultra-permeability, limited oil absorption, etc., and achieve good elasticity and elasticity Recovery, high flexibility and permeability, good stretching and resilience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

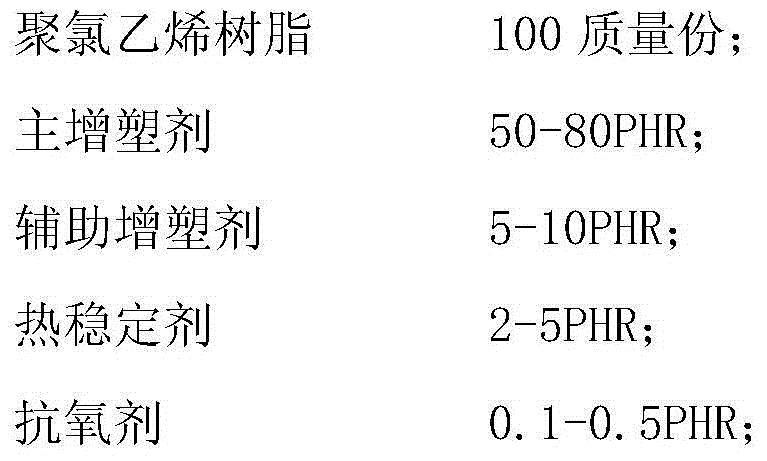

[0033] A high-elastic polyvinyl chloride weather-resistant flame-retardant ultra-transparent crystal diaphragm, including the proportion of each component:

[0034]

[0035] Among them, the general-purpose polyvinyl chloride resin is a PVC resin with a polymerization degree of 1300 and 1600 mixed in a ratio of 1:1; the main plasticizer is dioctyl phthalate; the auxiliary plasticizer is dioctyl adipate; The oxygen agent is bisphenol A; the elastic agent is liquid nitrile rubber; the hand-smoothing agent is erucamide; the processing aid is P551; the flame retardant is triphenyl phosphate; the colorant is ultramarine blue.

Embodiment 2

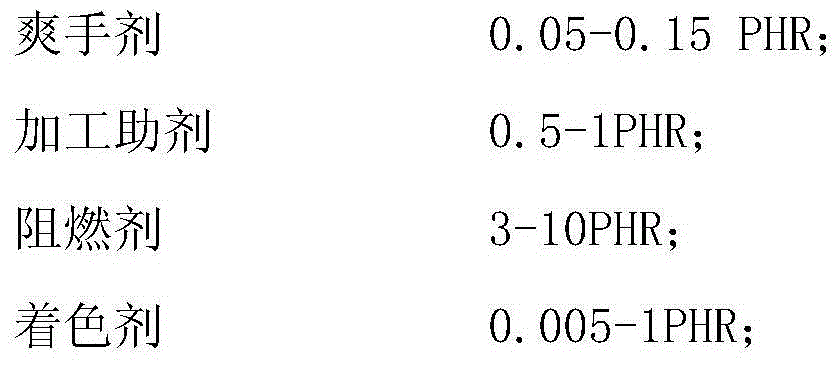

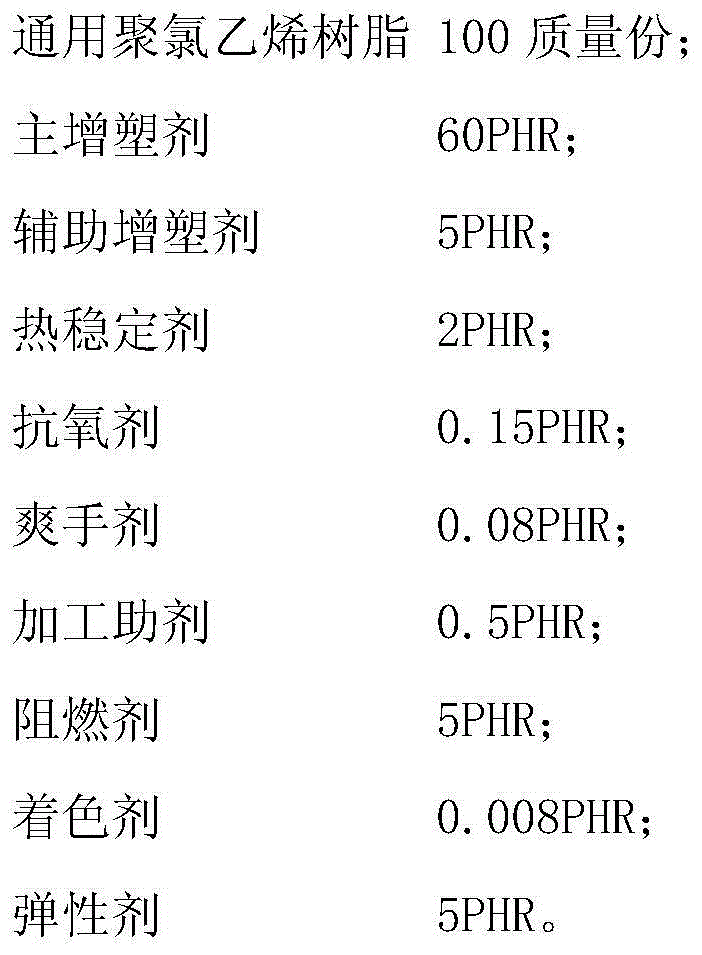

[0037] High-elastic polyvinyl chloride weather-resistant and flame-retardant ultra-transparent crystal diaphragm, including the distribution ratio of each component is

[0038]

[0039] Among them, the general-purpose polyvinyl chloride resin is a PVC resin with a polymerization degree of 1300; the modified polyvinyl chloride resin is a binary vinyl chloride resin; the main plasticizer is dioctyl phthalate; the auxiliary plasticizer is adipic acid Dioctyl ester; Bisphenol A as antioxidant; Ethylene bis stearamide as hand sanitizer; P551 as processing aid; Triphenyl phosphate as flame retardant; Permanent violet as coloring agent.

Embodiment 3

[0041] A method for preparing a high-elastic polyvinyl chloride weather-resistant flame-retardant ultra-transparent crystal diaphragm, the preparation process comprising the following steps:

[0042] After measuring polyvinyl chloride resin, plasticizer, heat stabilizer, antioxidant, hand sanitizer, processing aid, flame retardant, and colorant, perform high-speed mixing, and then transfer to cold stirring for cooling after high-speed mixing; The discharge temperature is 110°C; the mixed material is fed into the planetary extruder for plasticization, and the temperature of each zone of the planetary extruder is 170-200°C; the completely plasticized material is put into the filter for filtration and fed to the calender; the filter The temperature of each zone is 165-170°C; the temperature of the calender is preferably 180-220°C; the material is calendered to form a film of specified size, and then it is drawn into a purified water tank filled with demineralized water at a temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com