Calcium fluoride crystal containing europium, preparation method and application

A technology of calcium fluoride and crystals, which is applied in the field of preparation of calcium fluoride crystals containing europium, and can solve the problem that pure calcium fluoride crystals do not have scintillation fluorescence properties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

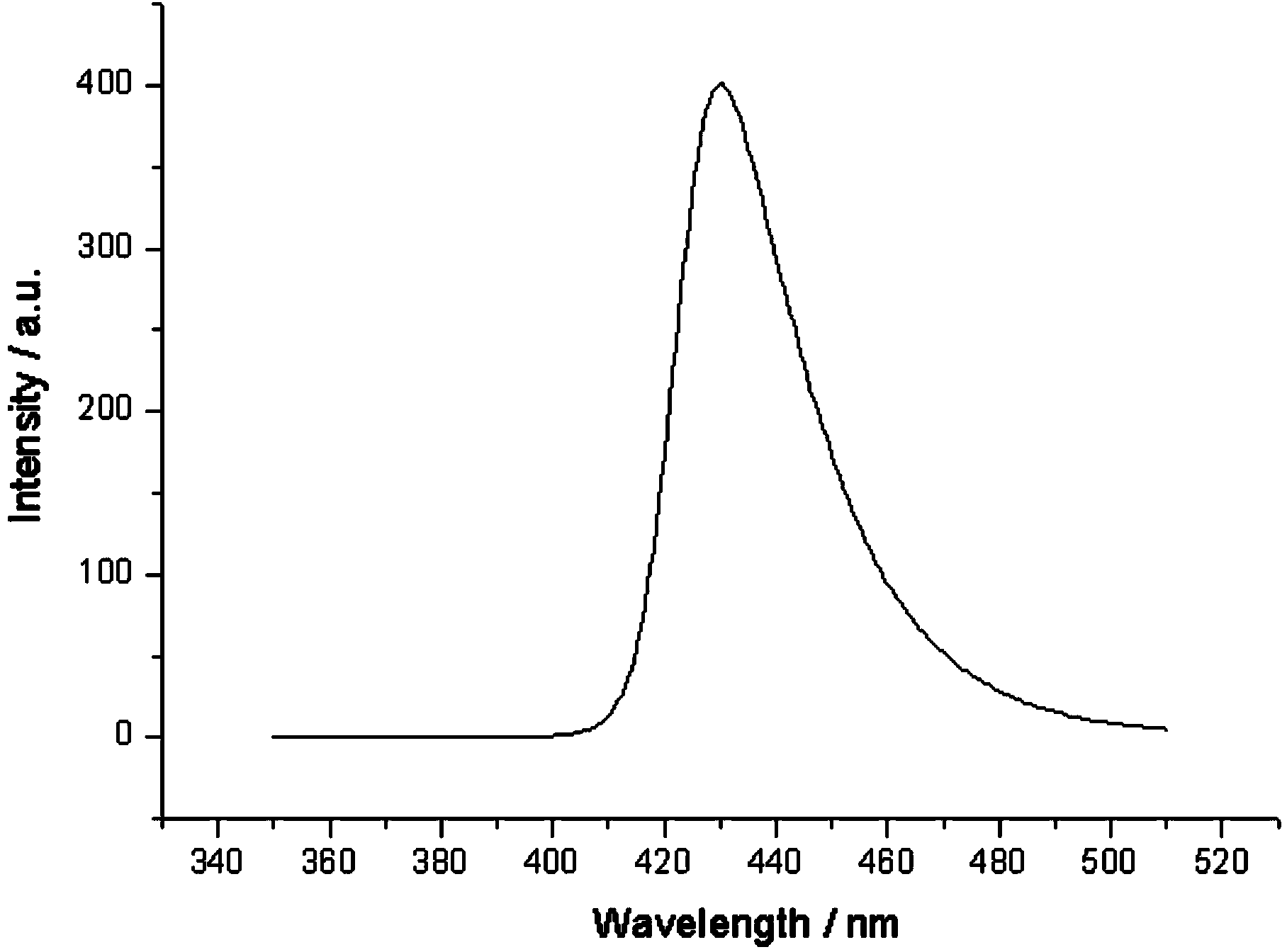

Image

Examples

preparation example Construction

[0036] The present invention also provides a method for preparing calcium fluoride crystals containing europium, said method comprising the following steps:

[0037] Step 1. Take calcium fluoride and europium fluoride powders in any content range and mix them thoroughly to obtain a mixture. Put the mixture in a vacuum drying oven after standing for 24 hours, and dry it at 200°C for 12 hours. , to obtain crystal-making raw materials;

[0038] Step 2. Put the crystal-making raw material obtained in the step 1 into a graphite crucible, place the crucible in a crystal growth furnace, and vacuumize the crystal growth furnace to 1.0×10 -3 Pa, the temperature is raised until the raw material is melted, the crucible is lowered at a speed of 5 mm / h, and the crystallization raw material is cooled to room temperature after the crystal-making raw material passes through the gradient zone completely to obtain the crystallization raw material;

[0039] Step 3, taking out the crystallizatio...

Embodiment 1

[0056] A kind of europium-containing calcium fluoride crystal preparation method provided by the invention specifically follows the steps below, and the preparation method comprises:

[0057] Step 1, get 1 kilogram of europium fluoride content (mass percentage) 0.5 * 10 -3 Wt% calcium fluoride and europium fluoride powders were fully mixed for 24 hours, then placed in a vacuum drying oven, and dried at 200°C for 12 hours;

[0058] Step 2, the content of europium fluoride in the calcium fluoride crystal is 0.5g, and the others are calcium fluoride crystals;

[0059] Step 3. Use the crucible to descend prepared by method.

[0060] crucible drop method Include the following steps:

[0061] 1) Add 1 kg of polycrystalline raw material obtained in the above steps to 1 gram of lead fluoride and mix evenly into a graphite crucible, put the graphite crucible into a descending furnace, and the crystal growth direction is or ;

[0062] 2) Vacuumize to make the vacuum inside t...

Embodiment 2

[0071] The present invention also provides a method for preparing calcium fluoride crystals containing europium, the preparation method comprising:

[0072] Step 1, raw material pretreatment step: take 1 kilogram of calcium fluoride and europium fluoride powder, the content is (mass percentage) 5 × 10 -3 % by weight, fully mixed for 24 hours, put in a vacuum drying oven, and dried at 200°C for 12 hours, wherein the content of europium fluoride in calcium fluoride crystals is 5g, and the remaining 995 grams are calcium fluoride crystals;

[0073] Step 2. Put 1 kg of crystal-making raw material obtained in step 1 into a graphite crucible, place the graphite crucible in a crystal growth furnace, and vacuumize the interior of the crystal growth furnace to 2×10 -3 Pa, the temperature is raised to the melting of raw materials, and the graphite crucible is lowered at a speed of 5mm / h, and the crystallization raw materials are lowered to room temperature to obtain crystallizat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com