Method for preparing lithium-rich manganese-based layered lithium battery cathode material based on efficient solid-phase chemical complexation reaction

A technology of solid-phase complexation and positive electrode materials, applied in battery electrodes, secondary batteries, electrochemical generators, etc., can solve the problem of low synthesis temperature and achieve the effects of low calcination temperature, low production cost and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

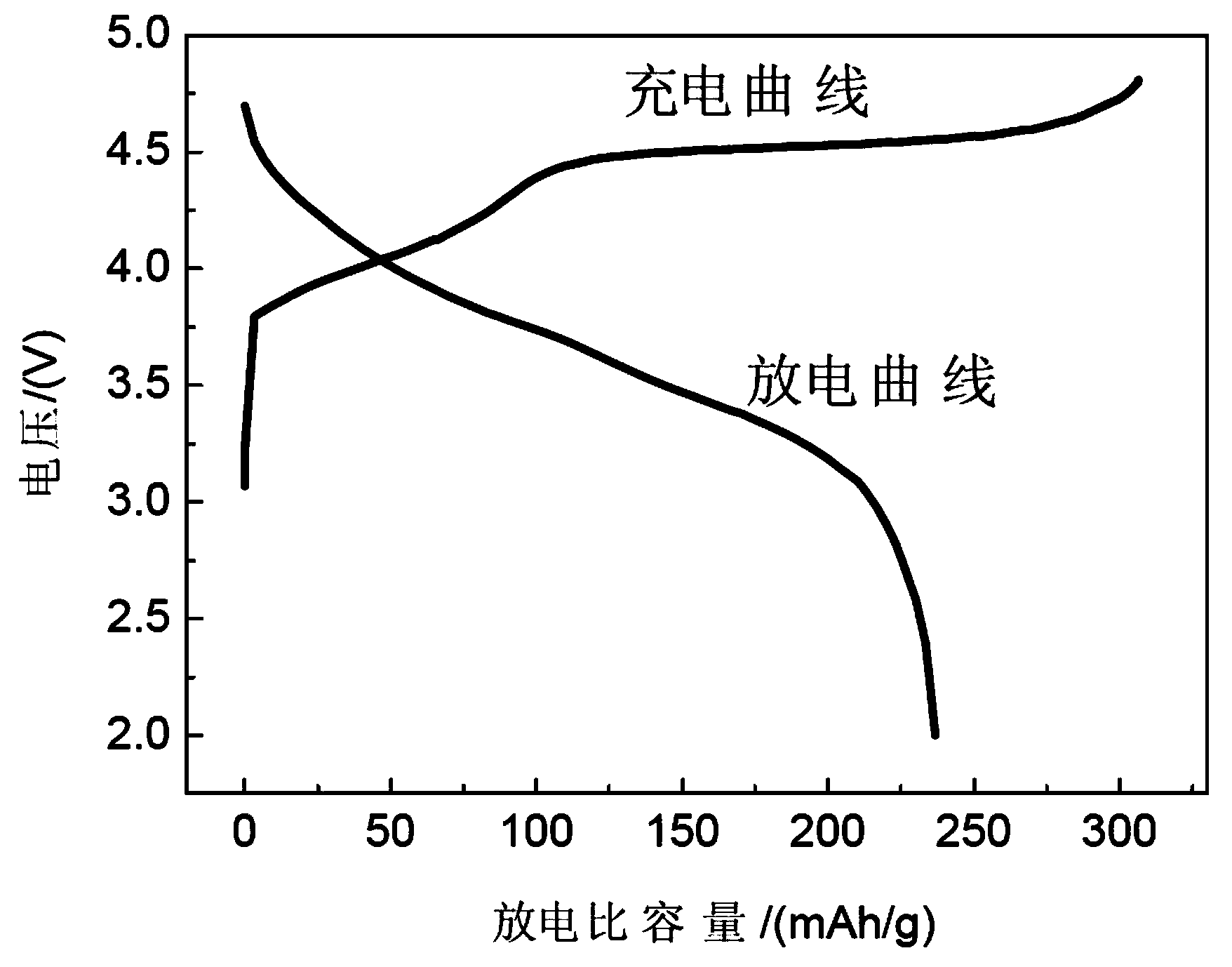

[0047] a kind of like figure 1 Shown the present invention based on solid-phase complexation chemical reaction to prepare lithium-rich manganese-based layered lithium battery cathode material (molecular formula is: Li[Li 0.067 Ni 0.138 co 0.148 mn 0.647 ]O 2 ) method, comprising the following steps:

[0048] (1) Material preparation: prepare lithium nitrate, nickel acetate, cobalt nitrate and manganese acetate used as raw materials, prepare citric acid used as solid coordination complexing agent;

[0049] (2) Grinding: according to the molecular formula (Li[Li] 0.067 Ni 0.138 co 0.148 mn 0.647 ]O 2 ), the raw materials prepared in the step (1) and the solid coordination complexing agent were dry-mixed evenly according to the ratio of 0.8:1, and ball milled at room temperature for 3 hours;

[0050] (3) drying the mixed material obtained in the above step (2) in an oven at 90° C. for 4 hours to obtain a solid-phase complex precursor;

[0051] (4) Place the solid-phase...

Embodiment 2

[0054] A kind of cathode material of lithium-rich manganese-based layered lithium battery prepared based on solid-phase complexation chemical reaction of the present invention (molecular formula is: Li[Li 0.157 Ni 0.138 co 0.134 mn 0.571 ]O 2 ) method, comprising the following steps:

[0055] (1) Material preparation: prepare lithium nitrate, nickel acetate, cobalt acetate and manganese acetate used as raw materials, prepare citric acid used as solid coordination complexing agent;

[0056] (2) Grinding: according to the molecular formula (Li[Li] 0.157 Ni 0.138 co 0.134 mn 0.571 ]O 2 ), the raw materials prepared in the step (1) and the solid coordination complexing agent were dry-mixed uniformly according to a molar ratio of 0.6:1, and ball milled for 2 hours at room temperature;

[0057] (3) drying the mixed material obtained in the above step (2) in an oven at 80° C. for 5 hours to obtain a solid-phase complex precursor;

[0058] (4) Place the solid-phase complex p...

Embodiment 3

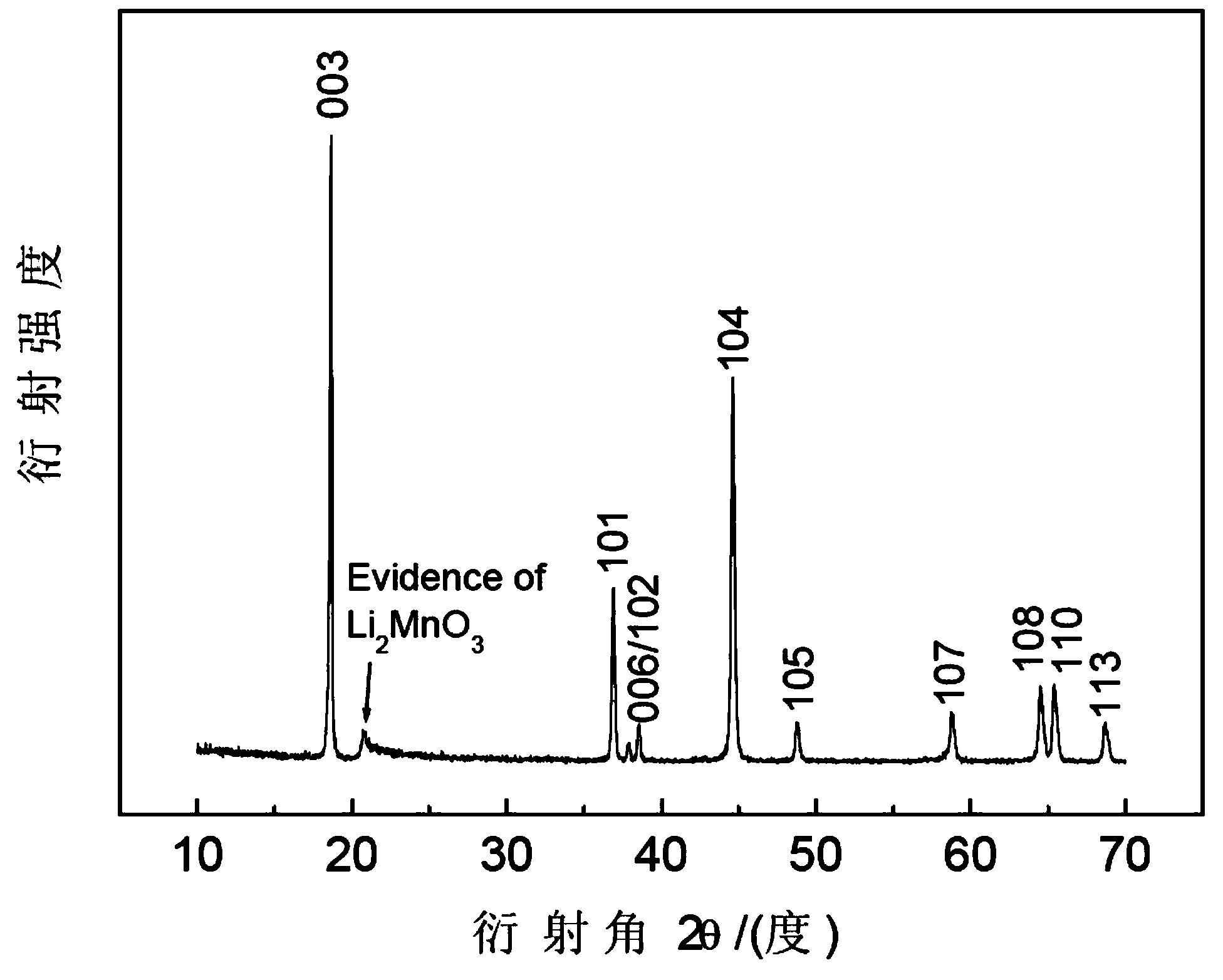

[0061] a kind of like image 3 Shown the present invention based on solid-phase complexation chemical reaction to prepare lithium-rich manganese-based layered lithium battery cathode material (molecular formula is: Li[Li 0.205 Ni 0.132 co 0.134 mn 0.529 ]O 2 ) method, comprising the following steps:

[0062] (1) Material preparation: prepare lithium acetate, nickel nitrate, cobalt nitrate and manganese acetate used as raw materials, prepare citric acid used as solid coordination and complexing agent;

[0063] (2) Grinding: according to the molecular formula (Li[Li] 0.205 Ni 0.132 co 0.134 mn 0.529 ]O 2 ), the raw materials prepared in step (1) and the solid coordination complexing agent were dry-mixed uniformly according to a molar ratio of 1:1, and ball milled at room temperature for 3.5 hours;

[0064] (3) drying the mixed material obtained in the above step (2) in an oven at 90° C. for 4 hours to obtain a solid-phase complex precursor;

[0065] (4) The solid-phas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| D50 | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com