Citrus fruit processing production method

A production method and technology of fruit pellets, applied in multi-step food processing, food science, food fractionation, etc., can solve the problems of large water consumption, high work intensity, unstable quality, etc., to reduce sewage discharge, improve production efficiency, The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

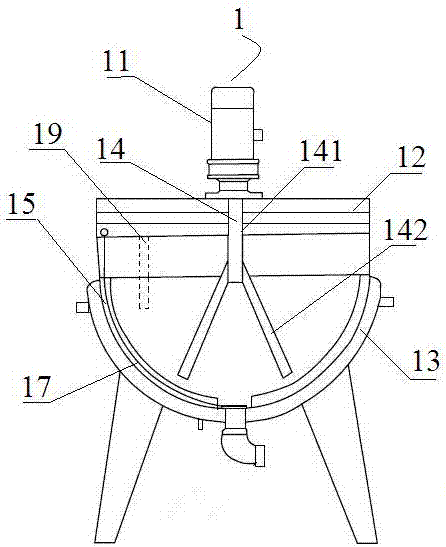

[0048] Such as figure 1 As shown, the citrus fruit grain processing production method, the production method is carried out according to the following steps: (1) raw material pretreatment: the raw tangerine slices are placed in the citrus immersion pool, soaked in acidic conditions for 1-12h;

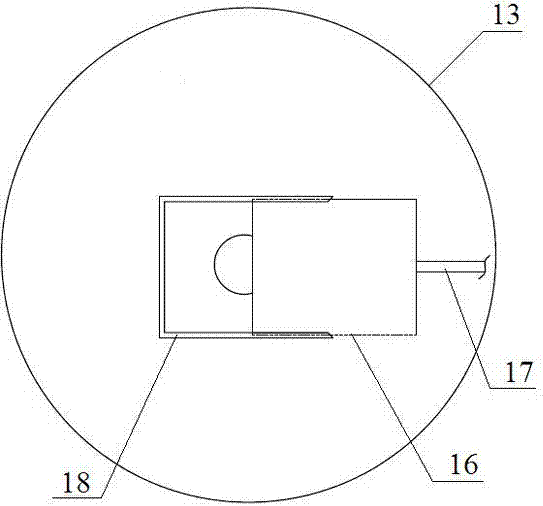

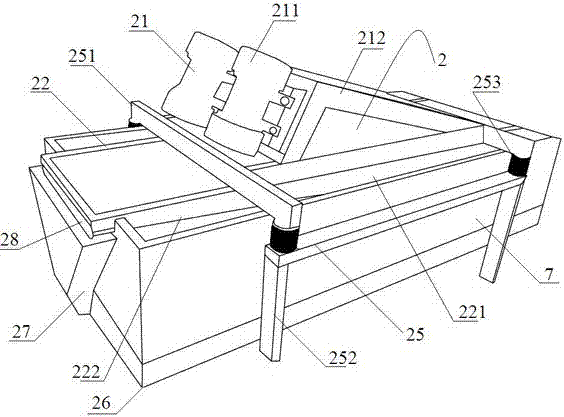

[0049] (2) Cleaning of raw materials: the orange slices that step (1) pretreated is lifted in the aeration type cleaning machine by the lifting mechanism, and the discharge port of the aeration type cleaning machine is equipped with a discharge device, and the discharge The device is composed of a box body and a rotatable hair roller in the box body. The cleaned orange slices are further removed from filamentous impurities through the hair roller and are ready for use;

[0050] (3) Raw material launder alkali treatment: the orange slices after step (2) cleaning are lifted into the alkali treatment launder system by the lifting mechanism for alkali treatment;

[0051] (4) Thermal separa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com