Method for manufacturing gold-solver alloy nanometer particles through sugarcane extract

A sugarcane extract and nanoparticle technology, applied in the direction of nanotechnology, can solve the problems of high preparation cost, poor dispersion of gold-silver alloy nanoparticles, environmental pollution, etc., and achieve low preparation cost, short preparation time and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

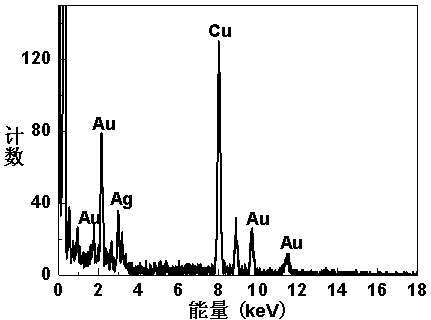

[0031] A method utilizing sugarcane extract to prepare gold-silver alloy nanoparticles, specifically comprising the steps of:

[0032] (1) Peel the sugarcane, squeeze the juice, filter, and centrifuge the obtained filtrate at a controlled speed of 8000rpm for 10min, and the obtained supernatant is the sugarcane extract;

[0033] (2), put 25 1 chloroauric acid aqueous solution and 5ml silver nitrate aqueous solution are mixed, with the rotating speed magnetic stirring of 200rpm 2min obtain mixed solution, the mol ratio of gold ion and silver ion in the mixed solution is 1:20;

[0034] The concentration of the chloroauric acid aqueous solution is 0.1M;

[0035] The concentration of the silver nitrate aqueous solution is 0.01M;

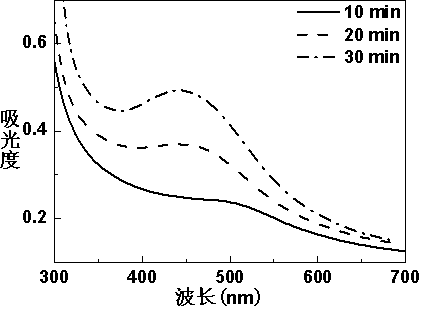

[0036] (3) Heat 3 parts of 25ml sugarcane extract to boiling within 10 minutes, respectively add 3 parts of the mixture obtained in step (2) into 3 parts of boiling sugarcane extract, keep boiling, and react for 10 minutes and 20 minutes respectively ...

Embodiment 2

[0043] A method utilizing sugarcane extract to prepare gold-silver alloy nanoparticles, specifically comprising the steps of:

[0044] (1) Peel the sugarcane, squeeze the juice, filter, and centrifuge the obtained filtrate at a controlled speed of 8000rpm for 10min, and the obtained supernatant is the sugarcane extract;

[0045] (2), put 25 1 chloroauric acid aqueous solution and 2.5ml silver nitrate aqueous solution are mixed, with the rotating speed magnetic stirring of 200rpm 2min obtains mixed solution, the mol ratio of gold ion and silver ion in the mixed solution is 1:10;

[0046] The concentration of the chloroauric acid aqueous solution is 0.1M;

[0047] The concentration of the silver nitrate aqueous solution is 0.01M;

[0048] (3) Heat 3 parts of 25ml sugarcane extract to boiling within 10 minutes, respectively add 3 parts of the mixture obtained in step (2) into 3 parts of boiling sugarcane extract, keep boiling, and react for 10 minutes and 20 minutes respective...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com