Environment-friendly high-luster weak solvent portrait medium and preparation method thereof

A low-solvent, high-gloss technology, applied in the field of digital imaging, can solve problems such as product scrapping, affecting printing accuracy, and easy sticking back, and achieve the effect of eliminating VOC emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

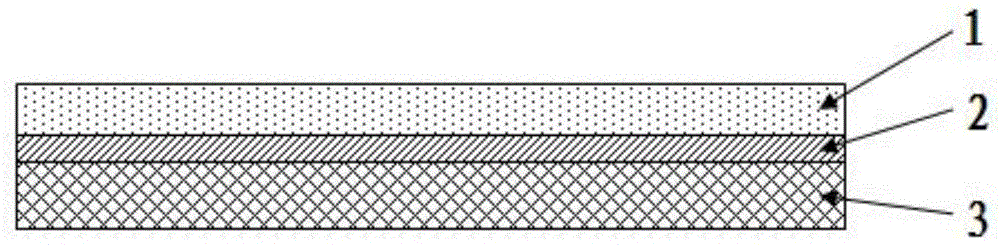

[0035] The preparation method of an environment-friendly high-gloss weak-solvent photo medium of the present invention comprises the following steps:

[0036] Step 1: Preparation of substrate 3; use Nanya's double-light PP synthetic paper with a thickness of 140 μm, a width of 1.29m, and a length of 3000m.

[0037] Step 2: Preparation of adhesion promotion layer 2 coating; weigh 50kg polyurethane emulsion, 26.6kg deionized water, 0.1kg defoamer, 0.1kg wetting agent, and add the above components in order to the mixing tank , start the agitator, stir for 0.5h to make the material mix evenly, filter with a 200-mesh filter, put it into a storage barrel and seal it for storage until coating.

[0038]Step 3: Preparation of high-gloss weak-solvent ink-absorbing layer 3; first weigh 64kg of polyurethane acrylate modified emulsion, add it to the batching bucket, start the agitator, and set the number of revolutions to 400RPM (not too fast to avoid foaming); then Add the following mate...

Embodiment 2

[0042] The preparation method of an environment-friendly high-gloss weak-solvent photo medium of the present invention comprises the following steps:

[0043] Step 1: Preparation of substrate 3; use Nanya's double-light PP synthetic paper with a thickness of 140 μm, a width of 1.29m, and a length of 3000m.

[0044] Step 2: Preparation of adhesion promotion layer 2 coating; weigh 50kg polyurethane emulsion, 26.6kg deionized water, 0.1kg defoamer, 0.1kg wetting agent, and add the above components in order to the mixing tank , start the agitator, stir for 0.5h to make the material mix evenly, filter with a 200-mesh filter, put it into a storage barrel and seal it for storage until coating.

[0045] Step 3: Preparation of high-gloss weak-solvent ink-absorbing layer 3; first weigh 64kg of polyurethane acrylate modified emulsion, add it to the batching bucket, start the agitator, and set the number of revolutions to 400RPM (not too fast to avoid foaming); then Add the following mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com