Cloprostenol sodium pure product preparation method

A technology of sodium cloprostenol, pure product, applied in the field of preparation of pure product of sodium cloprostinol, can solve the problems of long time, low purity, small sample loading, etc., and achieve low cost, high product purity, and sample loading A large amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] 1. Weigh 1.25g of the synthesized sodium chloroprostol powder, dissolve it in 25ml of pure ethanol, treat it with ultrasound, and filter it through a 0.45μm filter membrane to obtain a sample solution;

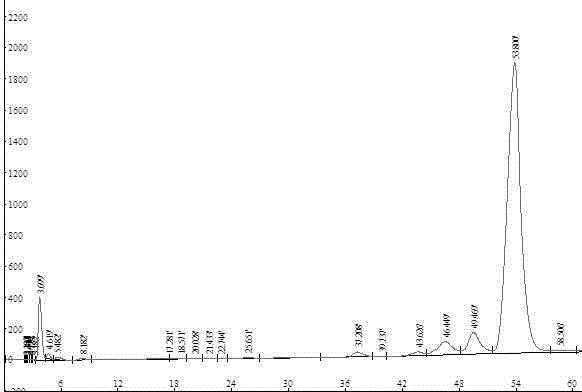

[0019] 2. Equilibrate the two column volumes with a 92:8 mobile phase of n-hexane / ethanol (containing 0.1% acetic acid). Take the sample solution from step 1 and inject it into the industrial preparative liquid chromatography separation and purification system with a syringe. The column is eluted at equal degrees, the column packing size is Φ50×250mm, the packing is spherical silica gel, the particle size is 10um, the sample volume is 1.25g, the flow rate is 60ml / min, the detection wavelength of the UV-visible light detector is 220nm, and the collection retention time is 71~ For the 89min target fraction, continue to flush 1~2 column volumes with mobile phase solution to make all impurities flow out;

[0020] 3. Concentrate the collected fractions in a vacuum rotary evaporat...

Embodiment 2

[0022] 1. Weigh 20g of synthetic chloroprostol sodium powder, dissolve it in 25ml of pure ethanol, treat it with ultrasound, and filter it through a 0.45μm filter membrane to obtain a sample solution;

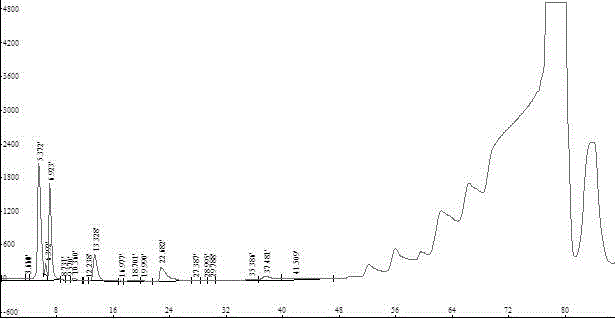

[0023] 2. Equilibrate the two column volumes with a 90:10 mobile phase of n-hexane / ethanol (containing 0.1% acetic acid), take the sample solution from step 1, and inject it into the industrial preparative liquid chromatography separation and purification system with a sample pump. Equivalent elution, the column packing size is Φ200×250mm, the packing is spherical silica gel, the particle size is 20um, the sample volume is 20g, the flow rate is 900ml / min, the detection wavelength of the UV-visible light detector is 220nm, and the collection retention time is 68~95min Continue to flush 1~2 column volumes with mobile phase solution to make all impurities flow out;

[0024] 3. The collected fractions were concentrated under reduced pressure in a vacuum rotary evaporator at 40°C to obta...

Embodiment 3

[0026] 1. Weigh 125g of synthetic chloroprostol sodium powder, dissolve it in 2.5Lml of pure ethanol, treat it with ultrasound, and filter through a 0.45μm filter membrane to obtain a sample solution;

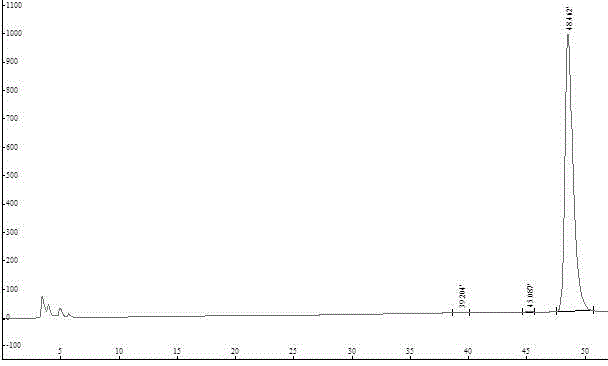

[0027] 2. Equilibrate the two column volumes of the column with a 95:5 mobile phase of n-hexane / ethanol (containing 0.1% acetic acid), take the sample solution from step 1, and inject it into the industrial preparative liquid chromatography separation and purification system with a sample pump. Equivalent elution, the column packing size is Φ500×250mm, the packing is spherical silica gel, the particle size is 20um, the sample volume is 125g, the flow rate is 4L / min, the detection wavelength of the UV-visible light detector is 220nm, and the collection retention time is 75~110min Continue to flush 1~2 column volumes with mobile phase solution to make all impurities flow out;

[0028] 3. The collected fractions were concentrated under reduced pressure on a vacuum rotary evaporator at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com