A kind of butene-1 polymerization catalyst and its preparation and application

A technology of catalyst and butene, which is applied in the field of butene-1 polymerization catalyst and its preparation and application, can solve the problems of narrow molecular weight distribution, unfavorable product processing, etc., and achieve the effects of improving performance, saving cost and improving processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

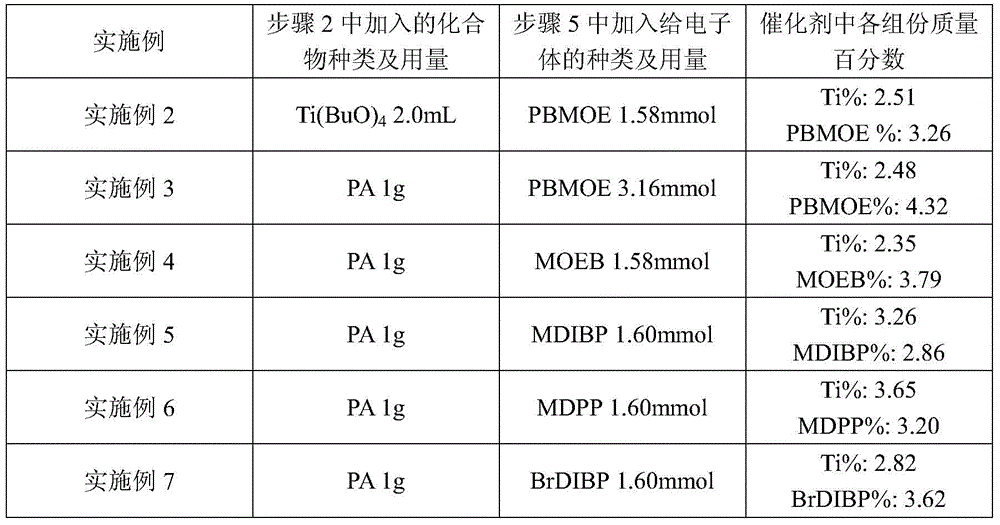

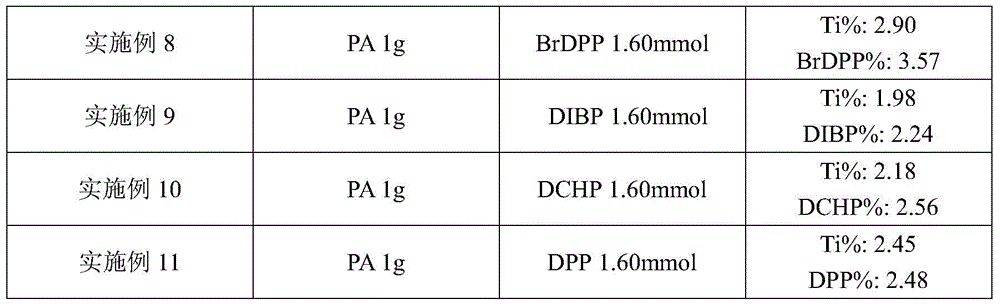

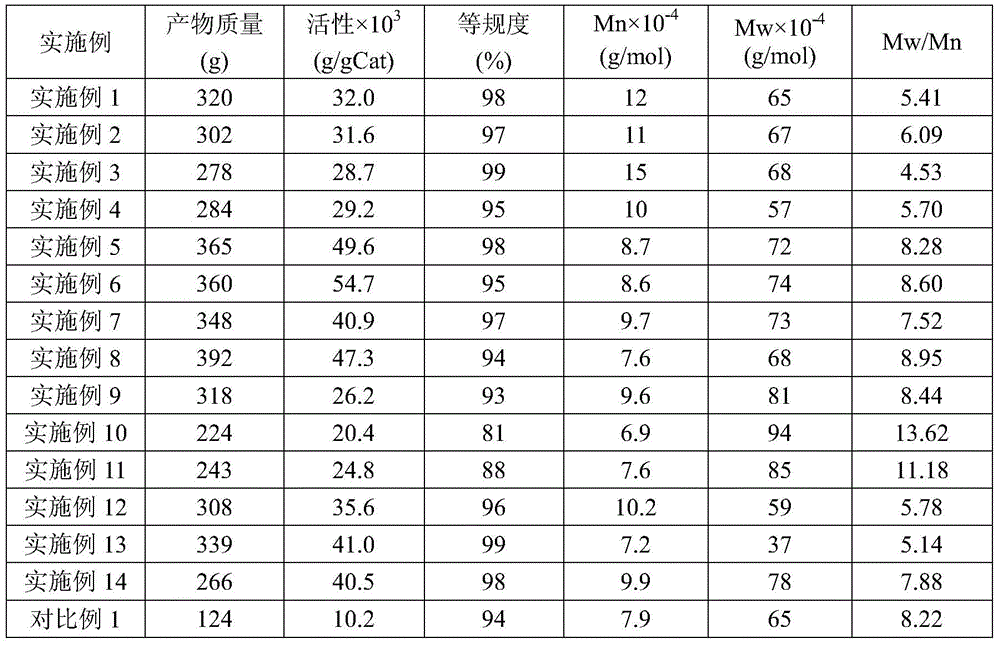

Examples

Embodiment 1

[0036] (1) Under the protection of high-purity argon, 60 mL of n-decane, 3.0 g of anhydrous magnesium chloride and 12.4 mL of isooctyl alcohol were successively added to a reactor with mechanical stirring, and the temperature was raised to 130 ° C for 2 hours to obtain a homogeneous phase solution A,

[0037] (2) Add 1 g of phthalic anhydride (PA) to the above reactant A solution, and react at 130°C for 2 hours to obtain reactant B, and cool to room temperature,

[0038] (3) Add all the reactants B obtained above dropwise to 100mL TiCl at a temperature of -10°C within 2 hours 4 In the solution, the temperature of the mixture was maintained at -10°C for 0.5 hours after the drop was completed, then the temperature was raised to 110°C within 6 hours under stirring, and this temperature was maintained for 2 hours to obtain a reaction mixture C,

[0039] (4) Reaction mixture C is separated by hot filtration to obtain solid product D,

[0040] (5) Then add 100mL TiCl to the solid ...

Embodiment 12

[0063] The process of Example 1 was repeated, except that the external electron donor was changed to diphenyldimethoxysilane (DDS), and other conditions remained unchanged. The results are listed in Table 2.

Embodiment 13

[0065] The process of Example 8 was repeated, except that the amount of hydrogen was increased to 0.15 MPa, and other conditions remained unchanged. The results are listed in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com