Mud-resistant polycarboxylate superplasticizer

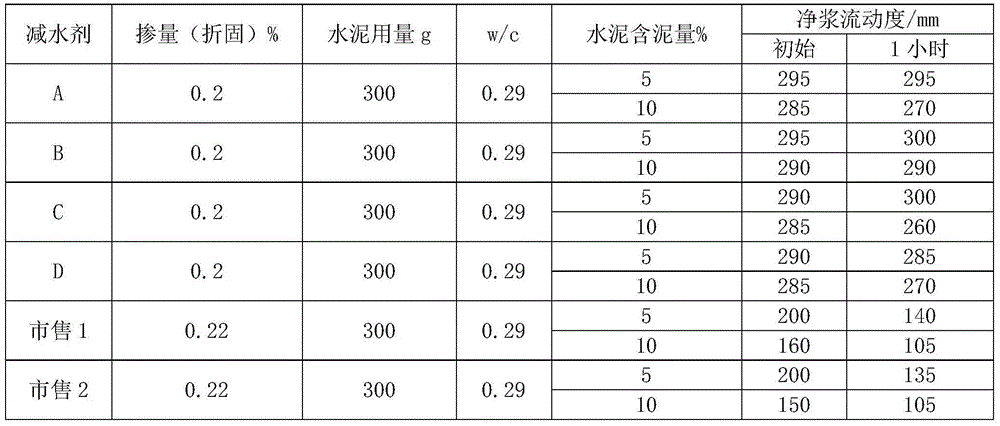

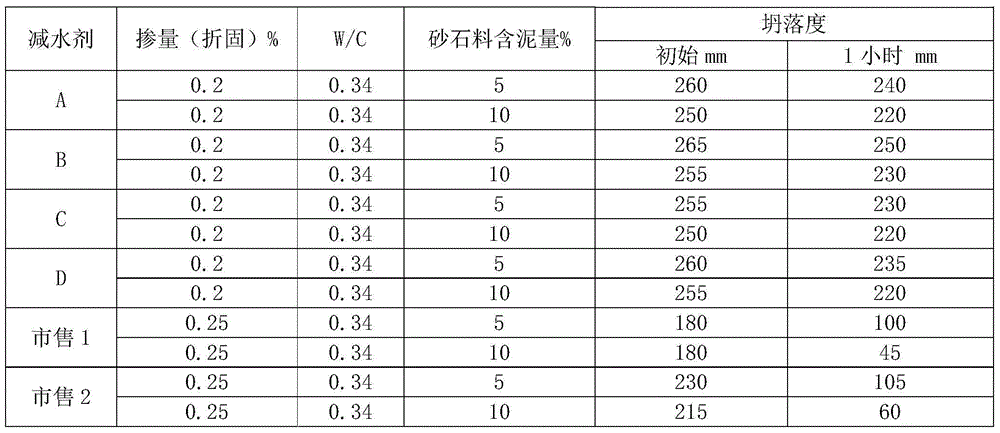

A technology of water reducing agent and polycarboxylic acid, which is applied in the design and manufacture of concrete admixtures, can solve the problems of high mud content in sand and gravel materials and cannot use polycarboxylic acid water reducing agent, etc., achieves high dispersing ability, inhibits adsorption , the effect of high collapse retention performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0007] Embodiment 1. A mud-resistant polycarboxylate water reducer, the water reducer is prepared from the following materials according to the weight ratio: 60 parts of polyethylene glycol dimethacrylate, lauryl 20 parts of sodium benzenesulfonate, 10 parts of maleic anhydride, 1-3 parts of thiourea, 5 parts of potassium permanganate, 5 parts of chain transfer agent mercaptopropanol, 150 parts of deionized water and 5 parts of 30% sodium hydroxide The carboxylic acid derivative is maleic anhydride or acrylic acid; the chain transfer agent is one of mercaptopropanol, mercaptoethanol, mercaptoacetic acid and isopropanol.

[0008] Preparation method: Add 60 parts of polyethylene glycol dimethacrylate and 150 parts of deionized water into the reaction kettle, stir and heat up to 80±2°C, after completely dissolving, add 20 parts of sodium dodecylbenzenesulfonate and 10 parts of maleic anhydride, continue to stir for 20 minutes, add 1 part of thiourea after complete dispersion, dro...

Embodiment 2

[0009] Embodiment 2. A mud-resistant polycarboxylate water-reducer, the water-reducer is prepared from the following materials in proportions by weight: 90 parts of polyethylene glycol dimethacrylate, lauryl 40 parts of sodium benzenesulfonate, 15 parts of acrylic acid, 3 parts of thiourea, 15 parts of potassium permanganate, 15 parts of chain transfer agent mercaptoethanol, 263 parts of deionized water and 15 parts of 30% sodium hydroxide; The compound is maleic anhydride or acrylic acid; the chain transfer agent is one of mercaptopropanol, mercaptoethanol, mercaptoacetic acid and isopropanol.

[0010] Preparation method: Add 90 parts of polyethylene glycol dimethacrylate and 263 parts of deionized water into the reaction kettle, stir and heat up to 80±2°C, after completely dissolving, add 40 parts of sodium dodecylbenzenesulfonate and 15 parts of acrylic acid, continue to stir for 20 minutes, add 3 parts of thiourea after complete dispersion, dropwise add 15 parts of potassi...

Embodiment 3

[0011] Embodiment 3. A mud-resistant polycarboxylate water reducer, the water reducer is prepared from the following materials according to the ratio of parts by weight: 75 parts of polyethylene glycol dimethacrylate, lauryl 30 parts of sodium benzenesulfonate, 13 parts of maleic anhydride, 2 parts of thiourea, 10 parts of potassium permanganate, 10 parts of chain transfer agent thioglycolic acid, 214 parts of deionized water and 10 parts of 30% sodium hydroxide; The carboxylic acid derivative is maleic anhydride or acrylic acid; the chain transfer agent is one of mercaptopropanol, mercaptoethanol, mercaptoacetic acid and isopropanol.

[0012] Preparation method: Add 75 parts of polyethylene glycol dimethacrylate and 214 parts of deionized water into the reaction kettle, stir and heat up to 80±2°C, after completely dissolving, add 30 parts of sodium dodecylbenzenesulfonate and 13 parts of maleic anhydride, continue to stir for 20 minutes, add 2 parts of thiourea after complete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com