Additive composition for polymer, preparation method of additive composition and flame-retardant thermoplastic polymer molding material by using additive composition

A polymer and additive technology, which is applied in the field of flame-retardant thermoplastic polymer molding materials, can solve the problems of screw corrosion in compounding combination devices, reduce energy and labor losses, have practicality, and reduce equipment processing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

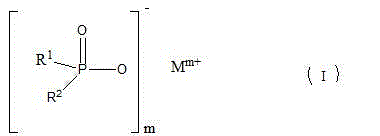

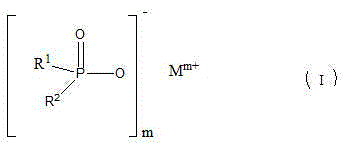

Method used

Image

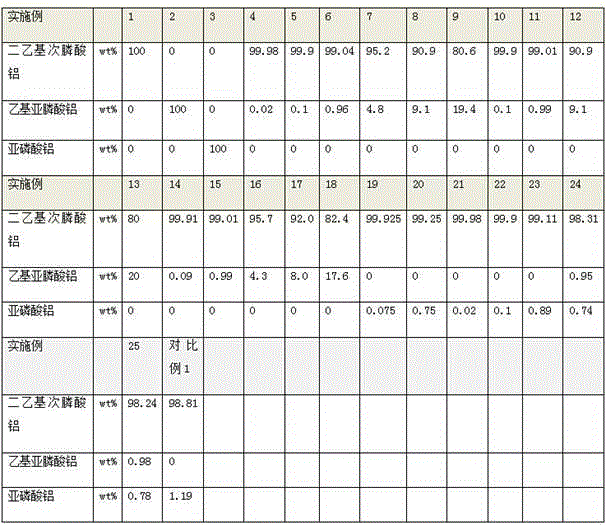

Examples

Embodiment 1

[0062] Embodiment 1: the preparation of one-component A aluminum diethylphosphinate

[0063] Hydroboration of 1060.0g (10mol) sodium hypophosphite monohydrate, 9.1g (0.3%mol hypophosphite ion) 1,1-di-tert-butylperoxy-3,3,5-trimethylcyclohexane, 3.0g Add sodium and 1500g water into the autoclave, evacuate it, replace it with nitrogen for 3 times, evacuate it, then fill it with ethylene through a pressure reducer and control the pressure at 2.0MPa, heat to 95°C for 5h, then raise the temperature to 100°C, and continue for 5h Add 18.1g (0.6% mol hypophosphite ion) of 1,1-di-tert-butylperoxy-3,3,5-trimethylcyclohexane, heat up to 100°C, keep warm for 1h, cool and vent to obtain diethyl The aqueous solution of sodium phosphinate is 3169.3g, which is equivalent to 579.1g of ethylene absorption (103.4% of the theoretical amount).

[0064] 31 P-NMR analysis:

[0065] Diethylphosphinic acid mol content: 98.1%

[0066] Ethylphosphonous acid mol content: 0%

...

Embodiment 2

[0070] Embodiment 2: the preparation of one-component B aluminum ethyl phosphinate

[0071] 1171.4g (10mol) 70% phosphorous acid, 9.1g (0.3%mol phosphorous acid) 1,1-di-tert-butylperoxy-3,3,5-trimethylcyclohexane and 3.0g sodium borohydride, Evacuate, replace with nitrogen for 5 times, evacuate, then fill with ethylene through the pressure reducer and control the pressure to 2.0MPa, heat to 90°C for 10h, and continuously add 18.1g (0.6% mol phosphorous acid) 1,1- Di-tert-butyl peroxide-3,3,5-trimethylcyclohexane, heated up to 100°C, kept warm for 1 hour, cooled and vented to obtain 1487.5g of ethylphosphonous acid solution, equivalent to ethylene absorption of 285.9g ( 102.1% of the theoretical amount).

[0072] 31 P-NMR analysis:

[0073] Ethylphosphonous acid mol content: 98.8%

[0074] Phosphorous acid mol content: 0%

[0075] Other mol content: 1.2%

[0076] Take 223.1g of its solution, add 1000g of water, heat and stir to 90°C, add dropwise 20% octadecahydrate alu...

Embodiment 3

[0077] Embodiment 3: the preparation of one-component C aluminum phosphite

[0078] Drop 1110.0g, 20wt% (0.33mol) aluminum sulfate aqueous solution into 1080g, 20wt% (1.0mol) sodium phosphite pentahydrate aqueous solution at a constant temperature of 80°C within 1 hour, filter, and wash the obtained filter cake three times with 1000ml water to obtain Aluminum phosphite 94.27g, yield: 95.22%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com