Electrochemical sensor based on graphene molecular imprinting material, and preparation method thereof

A molecular imprinting and graphene dispersion technology, applied in the fields of material electrochemical variables, analytical materials, scientific instruments, etc., can solve the problems of cumbersome process, destruction of graphene conjugated π structure, time-consuming and other problems, and achieves simple operation and low cost. , the effect of good conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

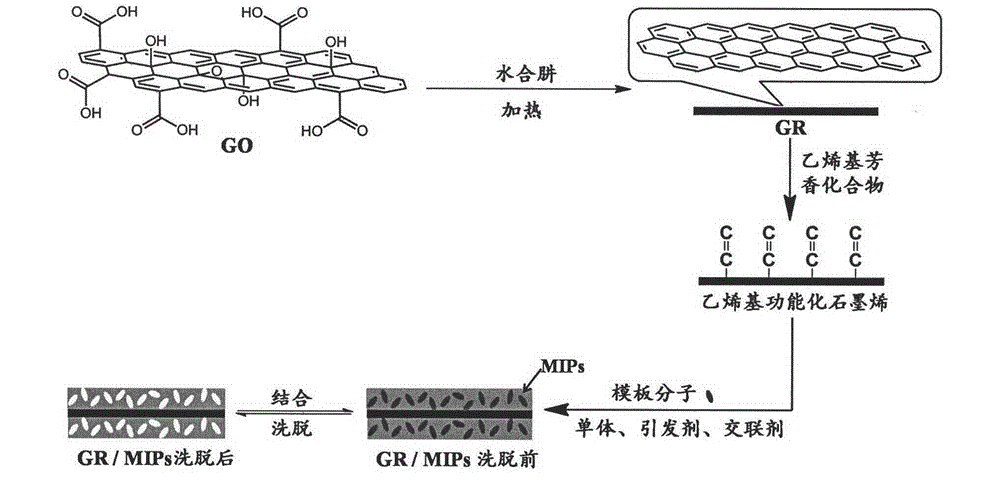

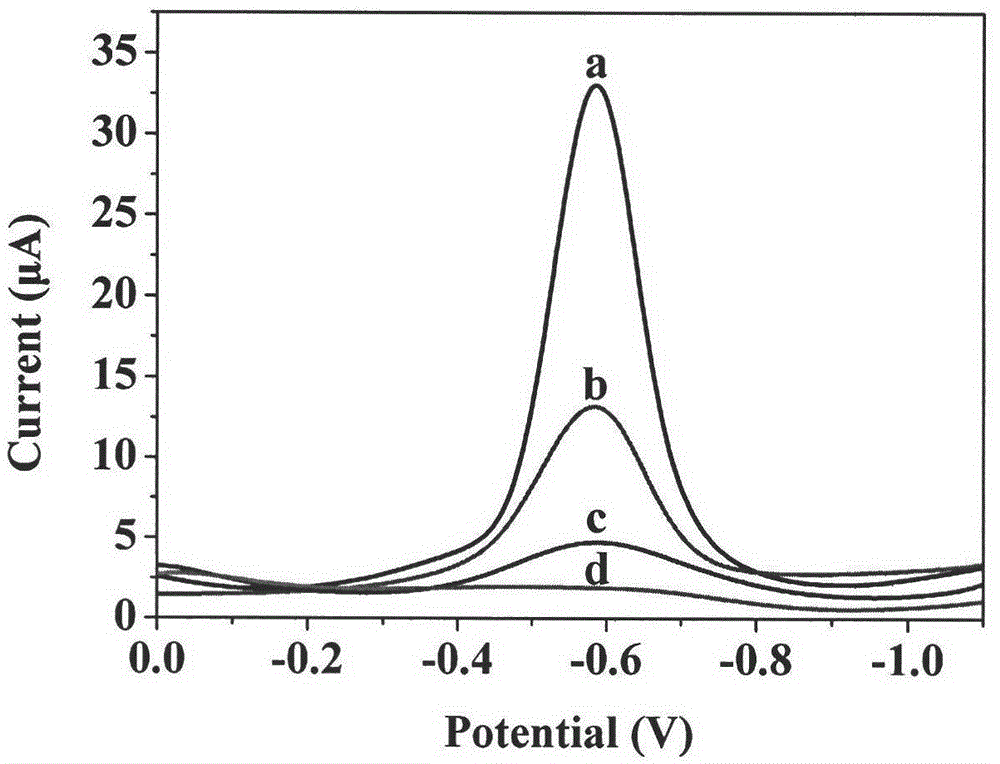

[0016] Dissolve 80 mg of GO in 80 mL of DMF, sonicate for 1 h to form a stable light brown graphene oxide solution, add 20 μL of hydrazine hydrate, and react at 70 °C for 2 h to obtain a black uniform suspension. Suction filtration and washing 3 times, adding a certain amount of DMF to obtain a GR / DMF solution. 40 mg of N-vinylcarbazole was added to 100 mL of 0.5 mg / mL GR / DMF solution, followed by sonication for 2 h to obtain a graphene / N-vinylcarbazole complex. Add comonomer styrene to graphene / N-vinylcarbazole solution, pass 10min N 2 , add template molecule p-nitrophenol (20mg), cross-linking agent EGDMA (2mmol), initiator AIBN (10mg), pass 15minN 2 , heated to 70 °C for 24 h, and the product was centrifuged and washed several times to obtain a molecularly imprinted polymer on the surface of graphene. Add 5 μL of polymer aqueous solution dropwise to the clean glassy carbon electrode and let it dry naturally. The imprinted molecules were eluted with absolute ethanol for 4...

Embodiment 2

[0018] Dissolve 50 mg of GO in 100 mL of DMF, sonicate for 1 h to form a stable light brown graphene oxide solution, add 20 μL of hydrazine hydrate, and react at 90 °C for 4 h to obtain a black uniform suspension. Suction filtration and washing 3 times, adding a certain amount of methanol to obtain a graphene solution. 10 mg of 9-vinyl anthracene was added to 30 mL of 1 mg / mL graphene solution, followed by sonication for 1 h to obtain a graphene / 9-vinyl anthracene composite. Add comonomer methacrylic acid to graphene / 9-vinyl anthracene solution, pass 10minN 2 , add template molecule caffeine (10mg), cross-linking agent EGDMA (4mmol), initiator AIBN (16mg), pass 15minN 2 , heated to 65°C and reacted for 12h, the product was repeatedly centrifuged and washed several times to obtain a molecularly imprinted polymer on the surface of graphene. Add 10 μL of polymer aqueous solution dropwise to the clean glassy carbon electrode and let it dry naturally. The imprinted molecules wer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com