Moisture-permeable waterproof fabric and method for manufacturing same

A moisture-permeable waterproof and fabric technology, which is applied in the field of moisture-permeable and waterproof fabrics, can solve the problems of reduced peel strength of synthetic resin films, low anti-bleeding effect, infiltration of synthetic resins, etc., and achieves the effect of excellent washing resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

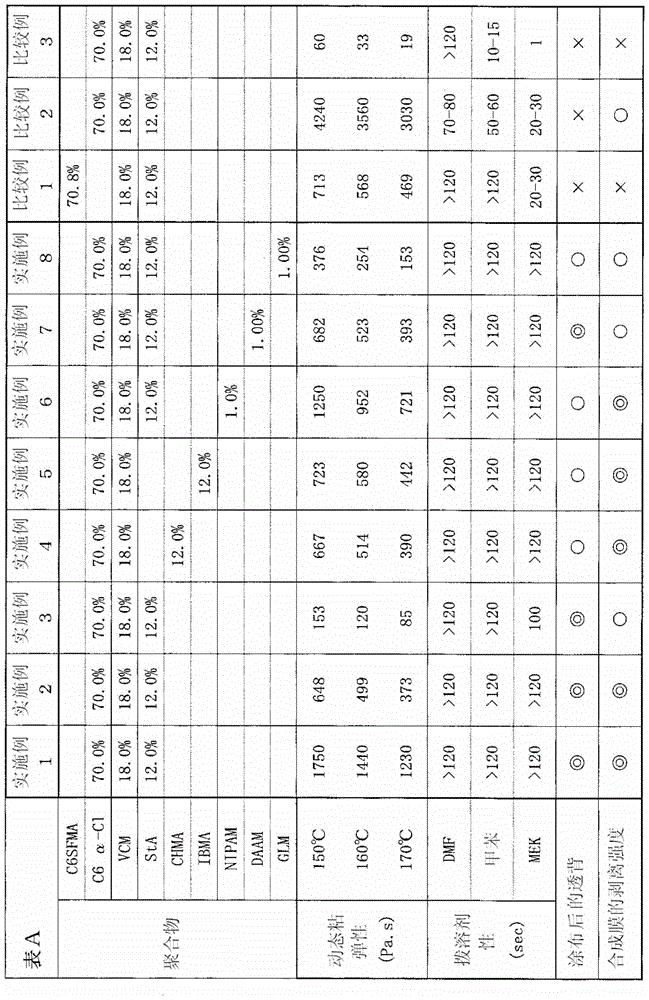

[0193] Add C to a 1 L autoclave 6 f 13 CH 2 CH 2 OCOCCl=CH 2 (C6α-Cl) 179g, stearyl acrylate 25g, tripropylene glycol 75.8g, pure water 446g, polyoxyethylene lauryl ether 12.7g, polyoxyethylene oleyl ether 2.47g, polyoxyethylene isodeca After heating 5.05 g of trialkyl ether and 2.66 g of dialkyl (tallow) dimethyl ammonium chloride at 60° C., they were emulsified and dispersed using a high-pressure homogenizer. After emulsification, 0.63 g of lauryl mercaptan was added, and 60 g of vinyl chloride was pressurized and filled. Furthermore, 1.92 g of 2,2- azobis(2-amidinopropane) dihydrochloride was added, and it was made to react at 60 degreeC for 3 hours, and the aqueous dispersion liquid of a polymer was obtained. The characteristics of the aqueous dispersion liquid whose concentration was adjusted with pure water so that the solid content concentration might become 30 weight% were measured. The results are shown in Table A.

Embodiment 2

[0195] Except having added 1.25 g of lauryl mercaptan after emulsification, the dispersion liquid of the polymer was obtained by the method similar to Example 1.

Embodiment 3

[0197] Except having added 1.88 g of lauryl mercaptan after emulsification, the dispersion liquid of the polymer was obtained by the method similar to Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com