Method for producing liquid sulfur dioxide by using sulfur-containing flue gas

A liquid sulfur dioxide and flue gas technology, applied in sulfur dioxide/sulfurous acid, chemical instruments and methods, specific gas purification/separation, etc., can solve problems such as single product, reduce production costs, improve economic benefits, and do not produce secondary The effect of pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

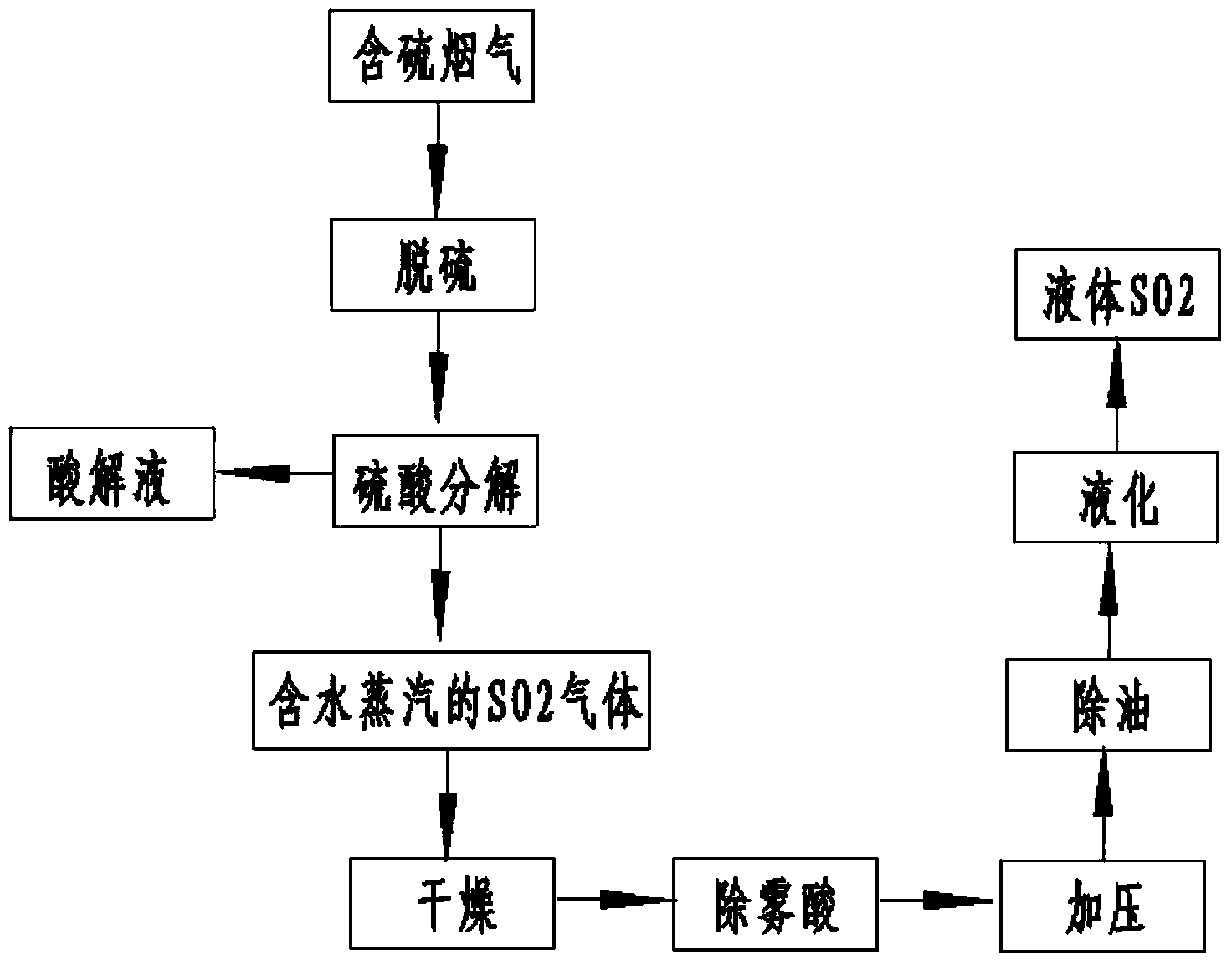

Image

Examples

Embodiment 1

[0026] a. The sulfur-containing flue gas (concentration of sulfur dioxide is 13210mg / Nm 3 ) is absorbed through ammonium sulfite solution (concentration is 254g / L) to obtain sulfur-containing absorption liquid; the concentration of sulfur dioxide in the absorbed sulfur-containing flue gas is 30mg / Nm 3 .

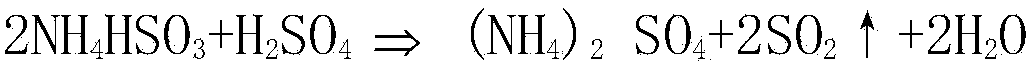

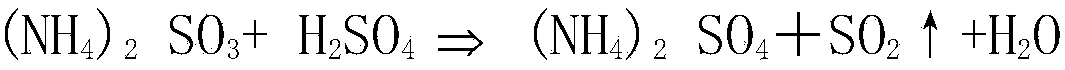

[0027] b. Decompose the sulfur-containing absorption solution by adding sulfuric acid with a concentration of 95% by volume to obtain acidolysis solution and SO containing water vapor 2 gas;

[0028] c, the SO containing water vapor 2 The gas is spray dried with sulfuric acid to SO 2 Gas water content≤0.2g / Nm 3 ; The amount of sulfuric acid spraying is 140m 3 / h. Removal of dry SO using nanofiber mist eliminators in drying 2 Acid mist brought by the gas process.

[0029] d. The dried SO 2 The gas is pressurized under the pressure condition of 0.25-0.7MPa, deoiled and liquefied to obtain liquid sulfur dioxide. The output is 116.14kg / h.

Embodiment 2

[0031] a. The sulfur-containing flue gas (concentration of sulfur dioxide is 14035mg / Nm 3 ) is absorbed through ammonium sulfite solution (concentration is 245g / L) to obtain sulfur-containing absorption liquid; the concentration of sulfur dioxide in the sulfur-containing flue gas after absorption is 35mg / Nm 3 .

[0032] b. Decompose the sulfur-containing absorption solution by adding sulfuric acid with a concentration of 90% by volume to obtain acidolysis solution and SO containing water vapor 2 gas;

[0033] c, the SO containing water vapor 2 The gas is spray dried with sulfuric acid to SO 2 Gas water content≤0.2g / Nm 3 ; The amount of sulfuric acid spraying is 160m 3 / h. Removal of dry SO using nanofiber mist eliminators in drying 2 Acid mist brought by the gas process.

[0034] d. The dried SO 2 The gas is pressurized under the pressure condition of 0.25-0.7MPa, deoiled and liquefied to obtain liquid sulfur dioxide. The output is 117.33kg / h.

Embodiment 3

[0036] a. The sulfur-containing flue gas (concentration of sulfur dioxide is 14655mg / Nm 3 ) is absorbed through ammonium sulfite solution (concentration is 251g / L) to obtain sulfur-containing absorption liquid; the concentration of sulfur dioxide in the sulfur-containing flue gas after absorption is 40mg / Nm 3 .

[0037] b. Decompose the sulfur-containing absorption solution by adding sulfuric acid with a concentration of 98.5% by volume to obtain acidolysis solution and SO containing water vapor 2 gas;

[0038] c, the SO containing water vapor 2 The gas is spray dried with sulfuric acid to SO 2 Gas water content≤0.2g / Nm 3 ; The amount of sulfuric acid spraying is 120m 3 / h. Removal of dry SO using nanofiber mist eliminators in drying 2 Acid mist brought by the gas process.

[0039] d. The dried SO 2 The gas is pressurized under the pressure condition of 0.25-0.7MPa, deoiled and liquefied to obtain liquid sulfur dioxide. The output is 115.67kg / h.

[0040] In the abov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com