Rice seedling raising peat soil matrix plate as well as preparation method and manufacturing machine of rice seedling raising peat soil matrix plate

A technology of rice seedling raising and peat soil, which is applied in the direction of planting substrate, botany equipment and methods, culture medium, etc., can solve the problems of not meeting the requirements of sustainable development, excessive excavation of eroded soil, backward technology, etc., and achieve strong water absorption and water retention, germination promotion, and nutrient-rich effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

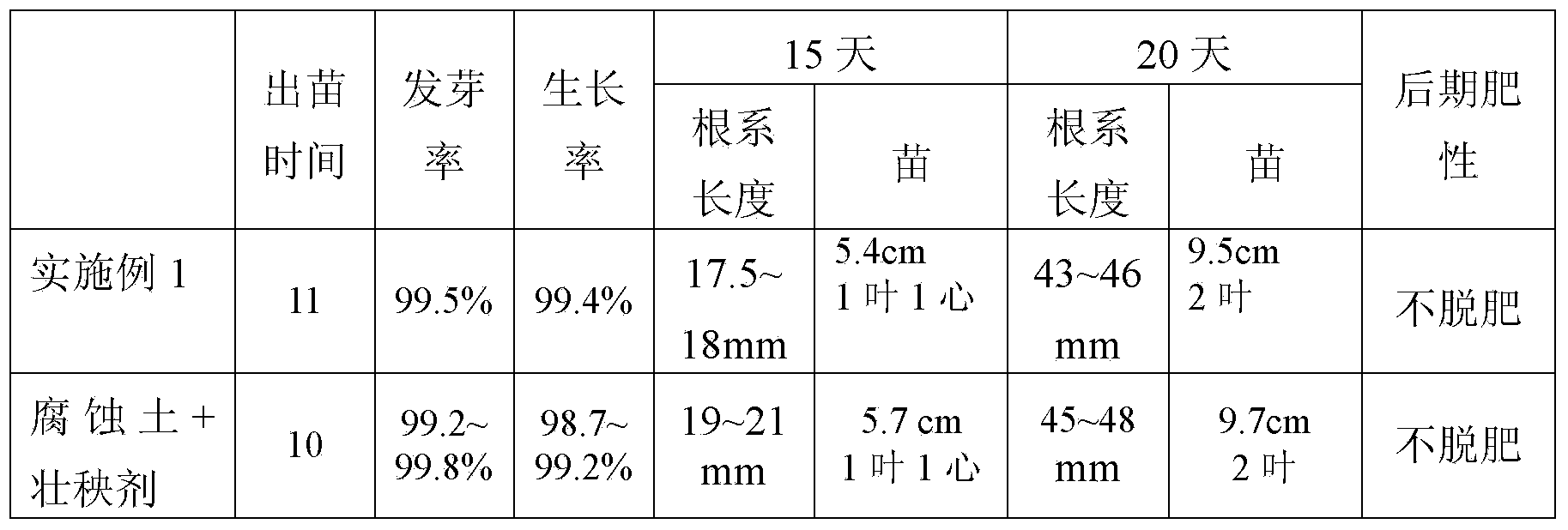

Examples

specific Embodiment approach 1

[0017] Specific embodiment one: the present embodiment rice seedling raising peat soil substrate plate is made up of 53~57 parts of coarse peat soil, 23~27 parts of fine peat soil, 13~17 parts of coconut shell powder and 4~5 parts by weight. made of pulp.

[0018] In this embodiment, pulp is used as a binder, which has the advantage of being environmentally friendly and degradable. After drying, the fibers in the pulp ensure the strength of the peat soil substrate for rice seedling raising. After watering during use, the fiber strength of the pulp is basically lost, making the substrate soft and useful for seed sowing and root growth and breathing.

[0019] Fine peat soil is rich in nutrients, and the nutrients account for about 60% of the mass of fine peat soil.

[0020] In this embodiment, the rice seedling raising peat soil matrix board is green and environmentally friendly, and the content of humic acid is more than 40%.

specific Embodiment approach 2

[0021] Specific embodiment two: In this embodiment, the peat soil matrix board for rice seedling raising is made of 55 parts of coarse peat soil, 25 parts of fine peat soil, 15 parts of coconut shell powder and 5 parts of paper pulp by weight.

specific Embodiment approach 3

[0022] Specific implementation mode three: In this implementation mode, the paddy rice seedling raising peat soil substrate board is prepared according to the following steps:

[0023] 1. Weigh the coarse peat soil, fine peat soil, and coconut shell powder according to the weight ratio of 53-57 parts of coarse peat soil, 23-27 parts of fine peat soil, 13-17 parts of coconut shell powder and 4-5 parts of paper pulp and pulp;

[0024] 2. Pour the coarse peat soil, fine peat soil and coconut shell powder into the beater, add clean water and beat to make primary pulp;

[0025] 3. Add paper pulp to the primary pulp prepared in step 2, refine pulp, and obtain raw material pulp;

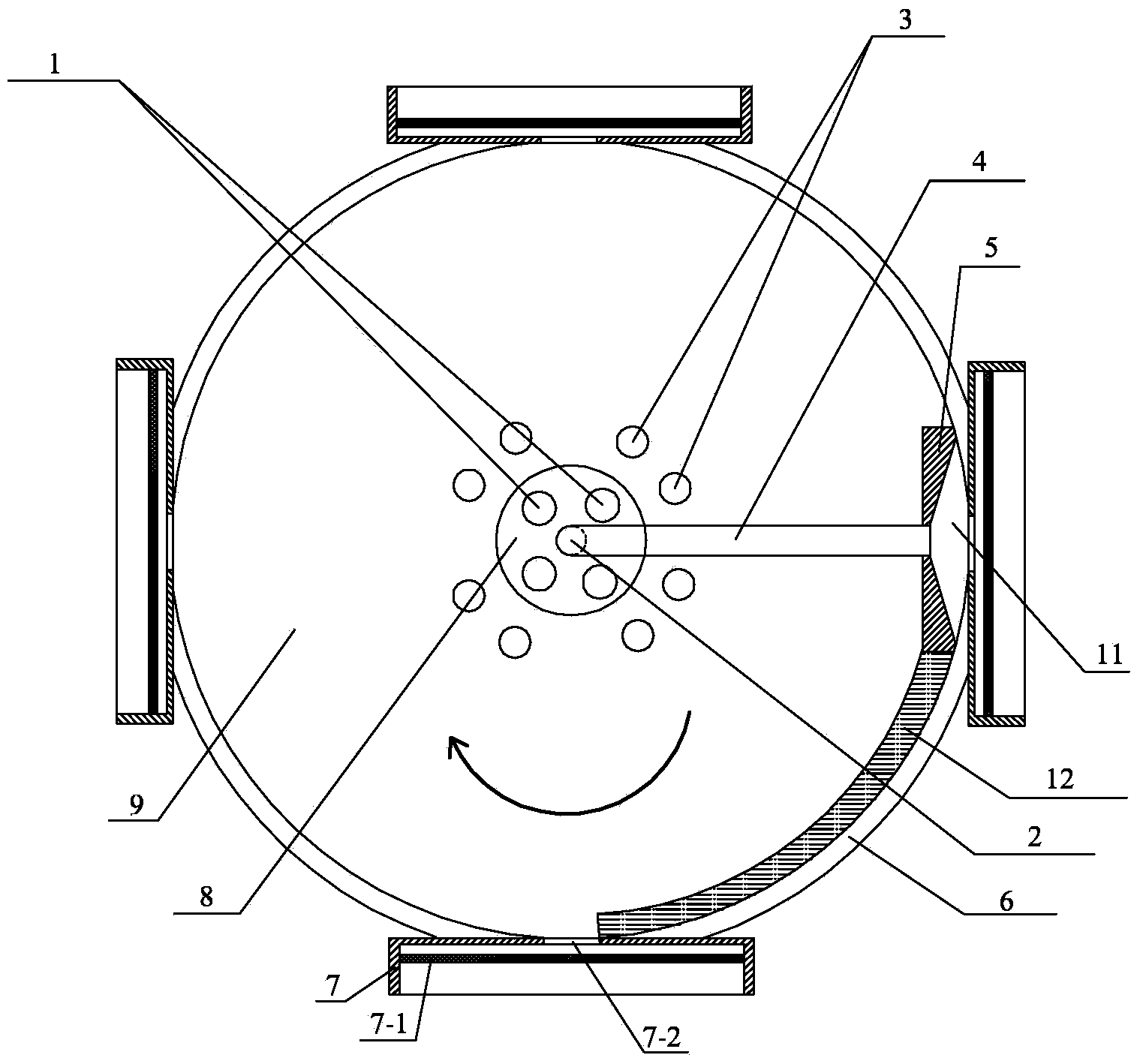

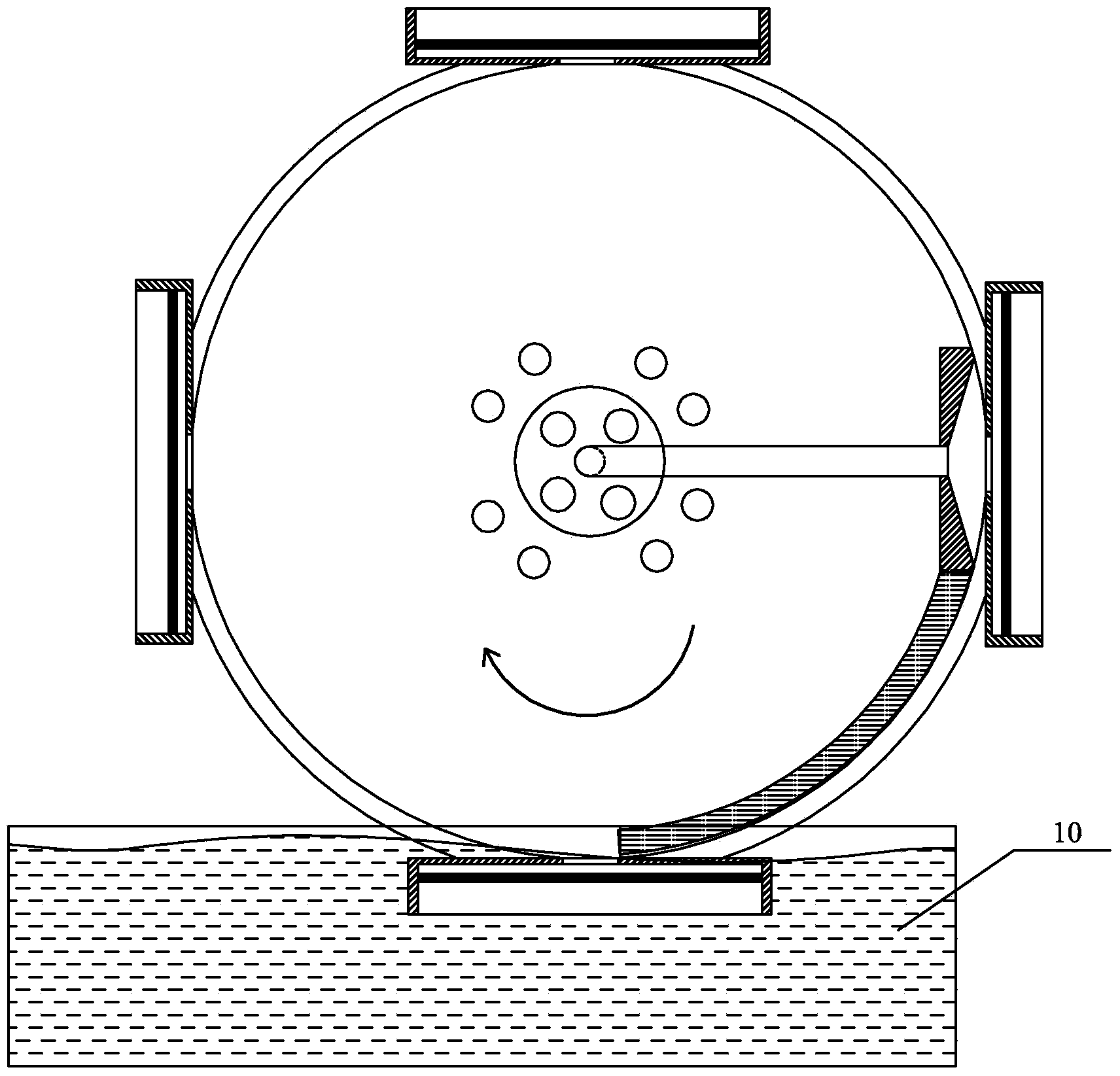

[0026] 4. The raw material slurry is stirred evenly and then poured into the material pool. The plate making machine uses the mold to suck out the raw material slurry in the material pool, and absorbs the moisture in the raw material slurry, and then blows the preliminarily formed matrix plate out of the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com