Pollution-free new technique for extracting diosgenin from yellow ginger

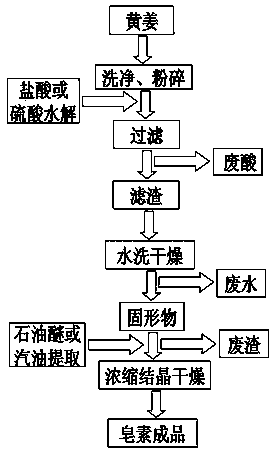

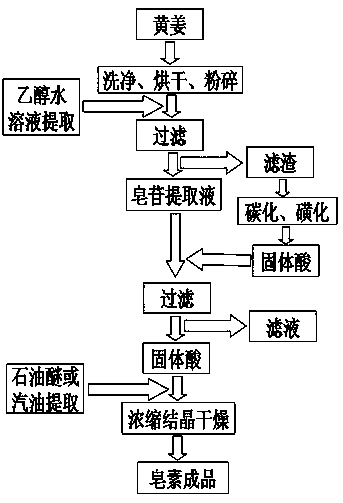

A technology of diosgenin and a new process, which is applied in the field of extraction of effective plant components, can solve the problems of low yield of saponin, large waste water pollution, waste of waste residue, etc., and achieve the effects of protecting the environment, realizing effective utilization, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Wash, slice, dry, and crush fresh turmeric through a 60-mesh sieve; weigh 15g of turmeric powder, add 150ml of distilled water, 50ml of industrial alcohol and 1.0g of sodium lauryl sulfate, stir magnetically for 20min, and sonicate for 30min at room temperature , then heated up in a water bath to 80°C, stirred magnetically for 3 hours, filtered after cooling, collected the filtrate, repeated the extraction of the filter residue once more according to the above process, combined the two filtrates to obtain a saponin extract, and determined that the yield of dioscin was 10.6 %. Dry the filter residue at 70 degrees for 12 hours, grind it, and then mix it according to the mass ratio of filter residue and concentrated sulfuric acid 1:9, stirring speed 300r / min, stirring time 12h, then carbonization, sulfonation, according to the mass of solid acid and the volume of water Wash the solid acid in a water bath at 80°C at a ratio of 1:3 for 4 times, and dry to obtain a carbon-bas...

Embodiment 2

[0028] Wash, slice, dry and crush fresh turmeric through a 40-mesh sieve; weigh 30g of turmeric powder, add 150ml of distilled water, 30ml of industrial alcohol and 0.5g of sodium lauryl sulfate, stir magnetically for 20min, and heat up to 90°C in a water bath. ℃, magnetically stirred for 2 hours, filtered after cooling, collected the filtrate, repeated the extraction of the filter residue twice according to the above process, combined the three filtrates to obtain a saponin extract, and the yield of dioscin was determined to be 9.59%. Dry the filter residue at 100°C for 8 hours, grind it, and then mix it according to the ratio of the mass ratio of the filter residue to concentrated sulfuric acid 1:15, the stirring speed is 450r / min, and the stirring time is 20h. Wash the solid acid in a water bath at 70°C at a ratio of 1:4 for 6 times, and dry to obtain a carbon-based solid acid catalyst. Take 50ml of saponin extract, add 9g of solid acid, put it in a water bath at 85°C f...

Embodiment 3

[0030] Wash, slice, dry and crush fresh turmeric through an 80-mesh sieve; weigh 40g of turmeric powder, add 150ml of distilled water, 90ml of industrial alcohol and 1.5g of sodium lauryl sulfate, stir magnetically for 20min, and sonicate for 45min at room temperature , then heated up in a water bath to 70°C, stirred magnetically for 4 hours, filtered after cooling, collected the filtrate, repeated the extraction of the filter residue 3 times according to the above process, combined the four filtrates to obtain a saponin extract, and the yield of dioscin was determined to be 9.82 %. The filter residue was dried at 110°C for 6 hours, ground, and then mixed according to the mass ratio of the filter residue to concentrated sulfuric acid of 1:25, the stirring speed was 600r / min, and the stirring time was 24 hours. Wash the solid acid in a water bath at 50°C at a ratio of 1:5 for 7 times, and dry to obtain a carbon-based solid acid catalyst. Take 50ml of saponin extract, add 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com