Cationic starch with conditioning and setting effect and preparation method thereof

A technology of cationic starch and cationic modifier, applied in skin care preparations, cosmetic preparations, hair care and other directions, can solve problems such as troublesome adjustment of dosage, difficult storage, transportation, etc., and achieves reduction of dosage and salt content. , the effect of a wide range of viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

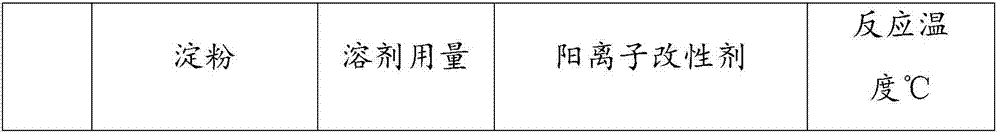

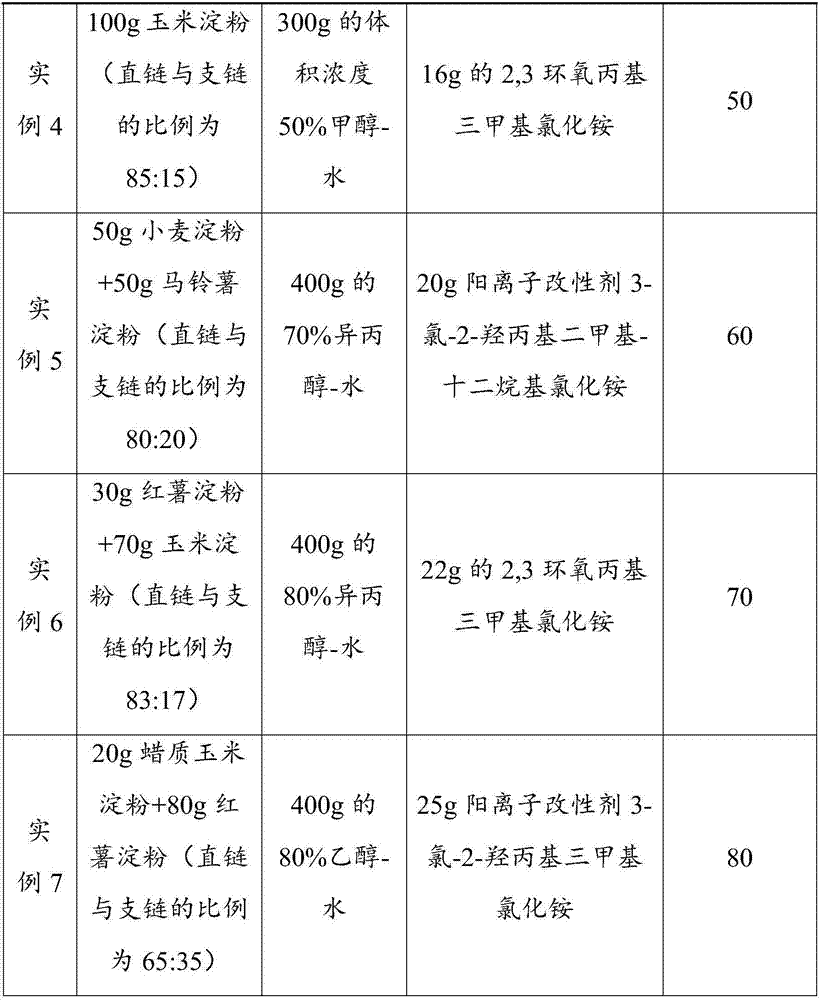

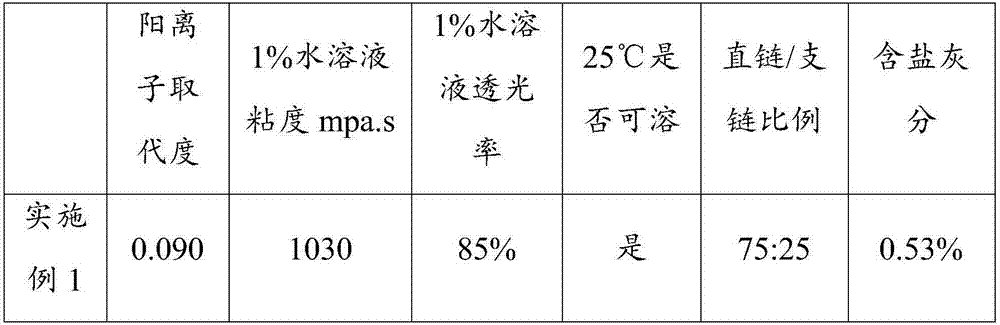

Examples

Embodiment 1

[0034]Get 100g tapioca starch (ratio of straight chain and branched chain is 75:25) and add reactor, evenly spray into 4g potassium hydroxide solution (concentration is 30wt%) and mix well, carry out alkalization, after that, add 25g cationic modifier 3-Chloro-2-hydroxypropyl dimethyl-dodecyl ammonium chloride is sprayed into the reaction kettle, and fully stirred to obtain a starch mixed slurry. Add 500 g (volume concentration: 50%) of ethanol aqueous solution into the reaction kettle to obtain alkalized starch suspension slurry. The temperature is limited to 80°C. After reacting for 2 hours, add acetic acid into the reaction kettle, stir and neutralize until the pH is 5-8, and obtain cationic starch suspension slurry. Afterwards, the cationic starch suspension slurry is centrifuged and dried to obtain the cationic starch with conditioning and setting effects.

Embodiment 2

[0036] Add 40g cassava and 60g cornstarch (ratio of straight chain to branched chain is 81:19) into the reaction kettle, evenly spray 4.5g of sodium hydroxide solution (concentration is 30wt%) and mix evenly, carry out alkalization, after that, 22g The cationic modifier 3-chloro-2-hydroxypropyltrimethylammonium chloride is sprayed into the reaction kettle, and fully stirred to obtain a starch mixed slurry. Add 300 g (50% volume content) of ethanol aqueous solution into the reaction kettle to obtain alkalized starch suspension slurry. The temperature is limited to 70°C. After reacting for 2.5 hours, add hydrochloric acid into the reaction kettle, stir and neutralize until the pH is 5-8, add excess acid to adjust the viscosity, and obtain cationic starch suspension slurry. Afterwards, the cationic starch suspension slurry is centrifuged and dried to obtain the cationic starch with conditioning and setting effects.

Embodiment 3

[0038] Add 10g of tapioca starch, 75g of potato starch, and 15g of waxy cornstarch (the ratio of straight chain to branched chain is 78:22) into the reaction kettle, evenly spray 4g of potassium hydroxide solution (concentration is 30wt%) and mix evenly, carry out alkali After that, 18g of cationic modifier 2,3 epoxypropyltrimethylammonium chloride was sprayed into the reaction kettle, and fully stirred to obtain starch mixed slurry. Add 200 g (50% volume content) of ethanol aqueous solution into the reaction kettle to obtain alkalized starch suspension slurry. The reaction temperature was limited to 70°C. After reacting for 1.5 hours, add sulfuric acid into the reaction kettle, stir and neutralize until the pH is 5-8, and obtain cationic starch suspension slurry. Afterwards, the cationic starch suspension slurry is centrifuged and dried to obtain cationic starch that can be used for conditioning and setting.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com