Odorless staining-resistant anti-yellowing UV coated matt finish paint coating, and preparation method and construction technology thereof

A technology of anti-yellowing and anti-fouling, which is applied in epoxy resin coatings, polyurea/polyurethane coatings, and devices for coating liquid on the surface, etc. It can solve the problem of incomplete curing of UV coatings and poor curing of UV coatings , bad smell and anti-scratch ability to achieve the effect of protecting the health of operators, fast curing, and high anti-scratch ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

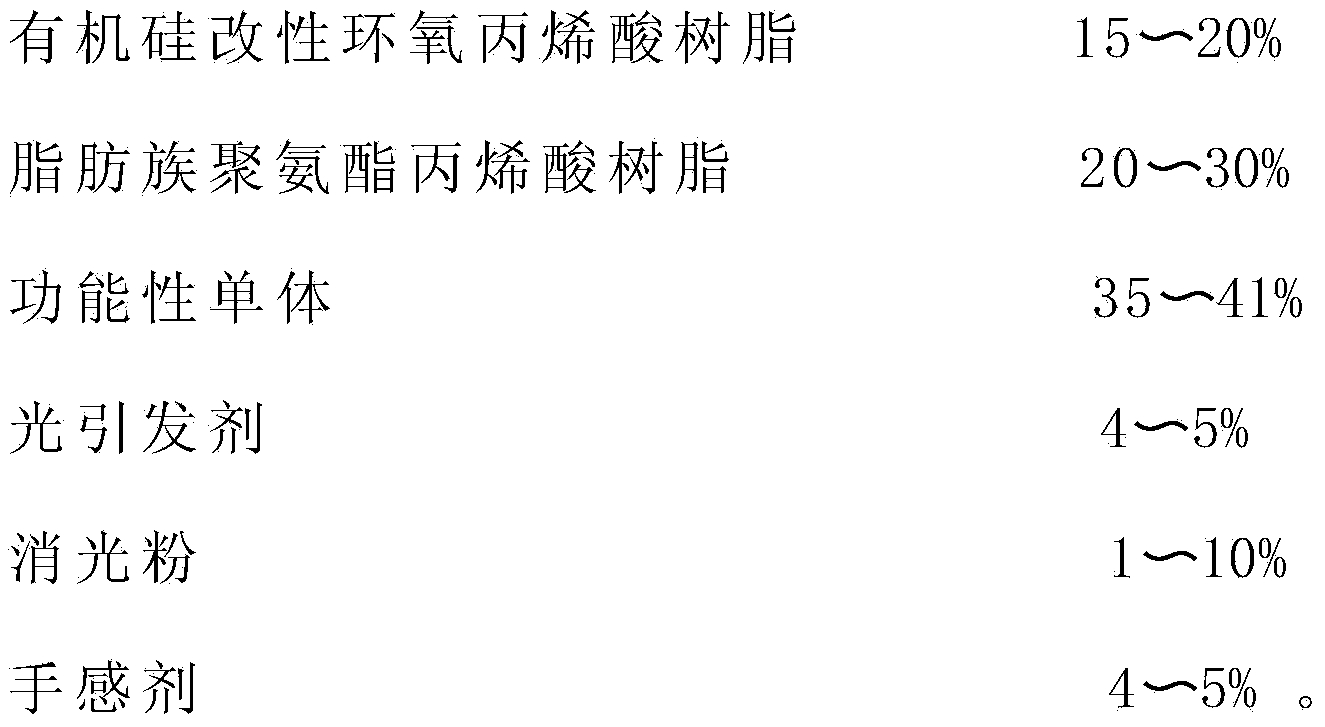

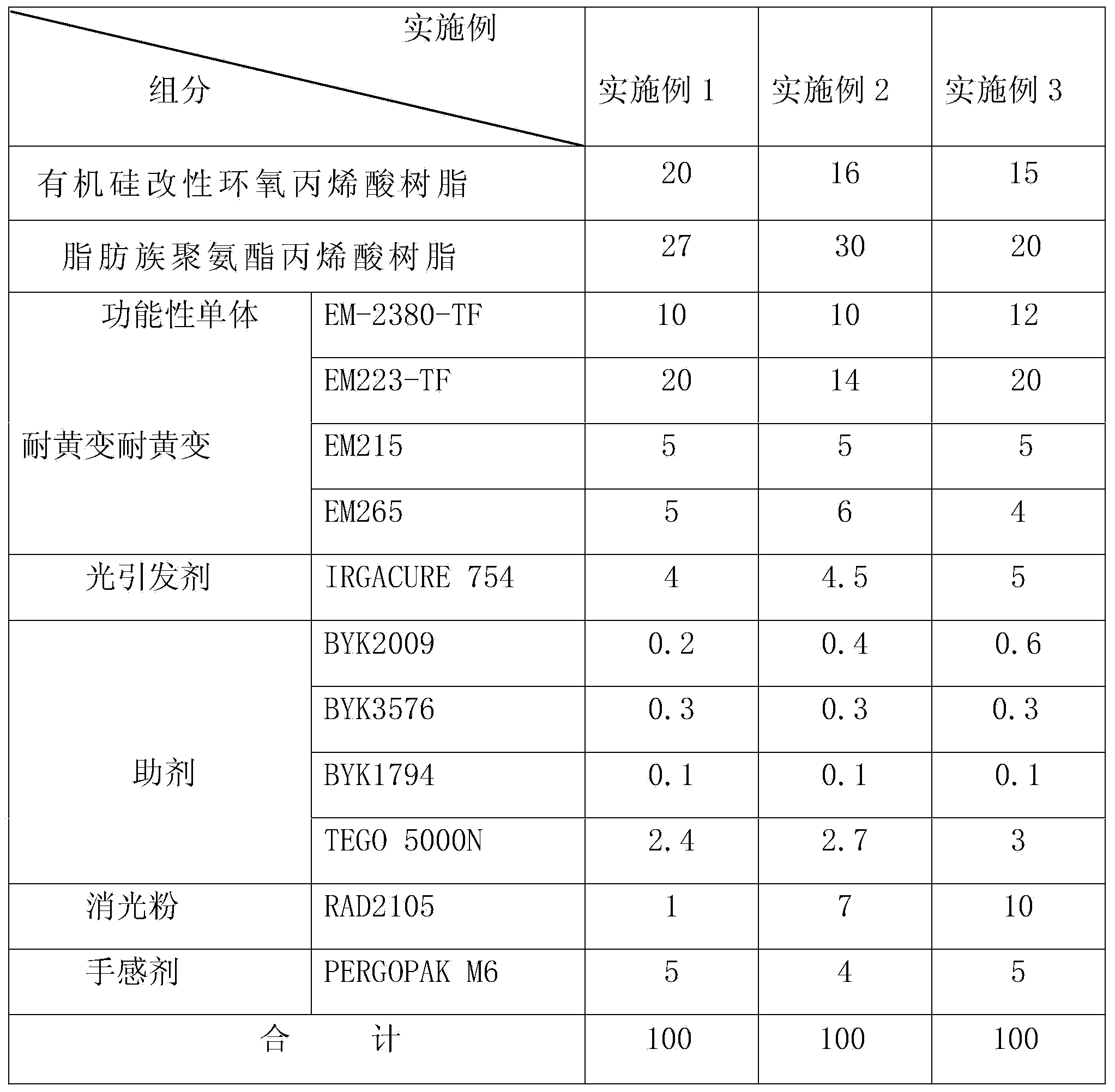

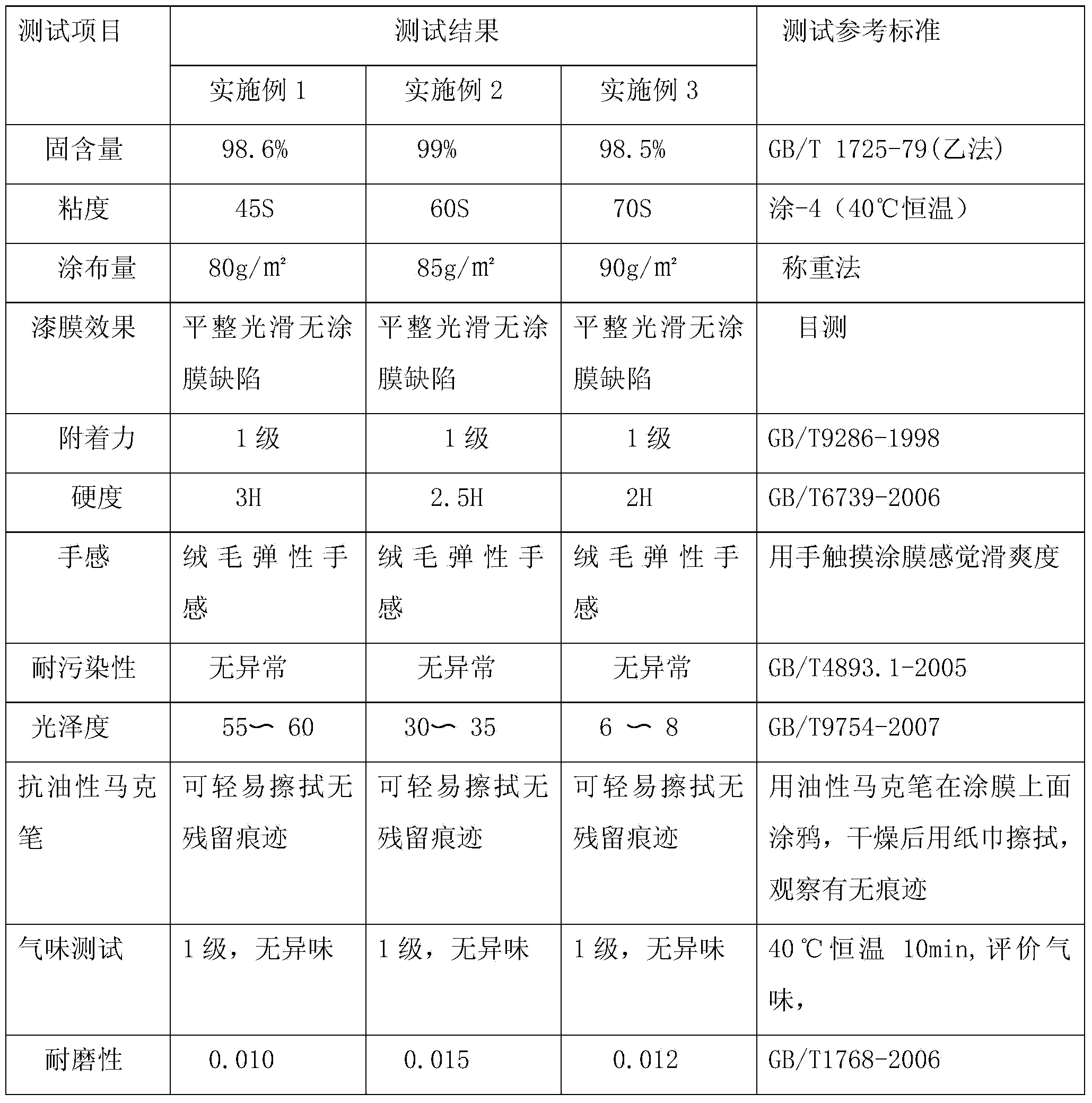

[0034] The raw material components and weight formulations (unit: kg) of Examples 1-3 are shown in Table 1.

[0035]

[0036] Table 1

[0037]Among them, the silicone-modified epoxy acrylic resin used in the present invention has the characteristics of weather resistance, heat resistance, abrasion resistance, and good pollution resistance, and can endow the coating film with good mechanical properties and simultaneously have yellowing and anti-fouling properties. Aliphatic urethane acrylate used in the present invention is anti-yellowing aliphatic urethane acrylate containing 4 functional groups, which has good toughness and yellowing resistance. Compared with epoxy acrylic resin, polyurethane acrylic resin is easier to use in matte system. Delustering, so the present invention uses polyurethane acrylic resin as the main resin and epoxy resin as a supplement. The monomers used in the present invention are all benzene-free reactive monomers, so as to ensure that benzene vola...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com