A high-strength friction-reducing and wear-resistant manganese-aluminum bronze alloy

A manganese-aluminum bronze and alloy technology, applied in the field of high-strength anti-friction and wear-resistant manganese-aluminum bronze alloy, can solve the problems of decreased fatigue resistance, increased segregation phenomenon, and high price of tin, and achieves good anti-seizure and low dry friction Factor effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

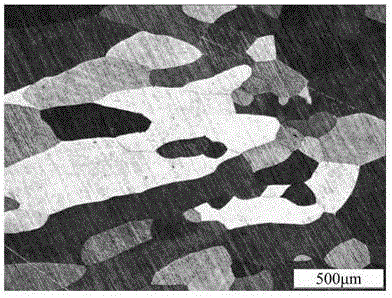

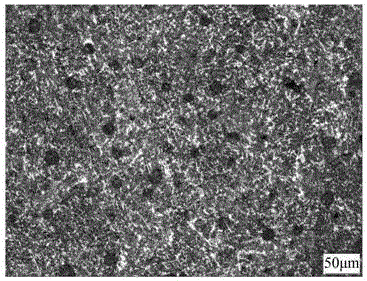

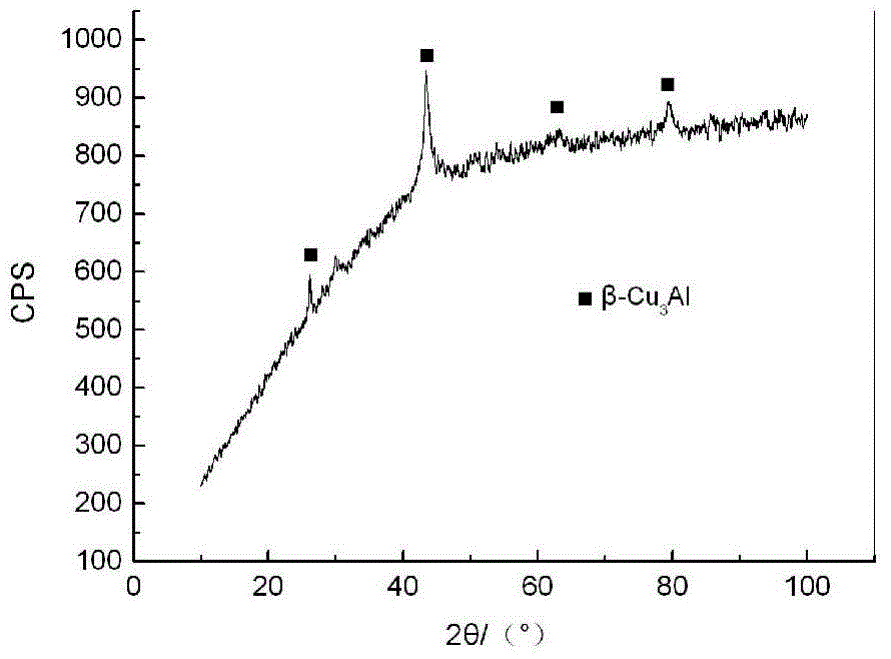

[0060] The raw materials are mixed according to the mass percentage: Mn8%, Al8%, Fe2.5%, Zn2.5%, Ce0.6%, and the balance Cu is smelted in a vacuum induction furnace at a melting temperature of 1230°C and kept for 10 minutes. Then, the alloy liquid with a pouring temperature of 1150°C is poured into a graphite mold with a diameter of 40 mm, and naturally cooled to obtain a circular ingot with a diameter of 40 mm; the alloy is β-Cu 3 The microhardness, tensile strength and elongation values of the Al single-phase solid solution structure are shown in Table 2; the friction and wear properties are shown in Table 3.

Embodiment 2

[0062] The raw materials are mixed according to mass percentage: Mn8.5%, Al8.5%, Fe2%, Si0.5%, Zn2%, Ce0.5%, B0.1%, and the balance Cu; smelting in a vacuum induction furnace, The melting temperature is 1240°C, and the temperature is kept for 10 minutes; then, pour the alloy solution with a pouring temperature of 1160°C into a graphite mold with a diameter of 40mm, and cool naturally to obtain a circular ingot with a diameter of 40mm; the alloy is β-Cu 3 The microhardness, tensile strength and elongation values of the Al single-phase solid solution structure are shown in Table 2; the friction and wear properties are shown in Table 3.

Embodiment 3

[0064] The raw materials are mixed according to mass percentage: Mn9%, Al9%, Fe2%, Zn2%, Ce0.7%, and the balance is Cu; it is melted in a vacuum induction furnace at a melting temperature of 1240°C and kept for 12 minutes; then, pouring The alloy liquid at a temperature of 1170°C is poured into a graphite mold with a diameter of 40mm, and naturally cooled to obtain a circular ingot with a diameter of 40mm; the alloy is β-Cu 3 The microhardness, tensile strength and elongation values of the Al single-phase solid solution structure are shown in Table 2; the friction and wear properties are shown in Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| microhardness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com