A high-performance friction-reducing and wear-resistant manganese-aluminum bronze alloy

A manganese-aluminum bronze, high-performance technology, applied in the field of high-performance anti-friction and wear-resistant manganese-aluminum bronze alloy, can solve the problems of deterioration of manufacturability, decrease of fatigue resistance, increase of segregation phenomenon, etc., to overcome low fatigue strength, good Seizure resistance, effect of low dry friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

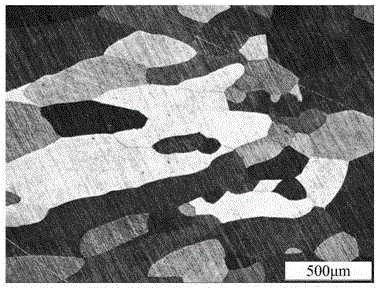

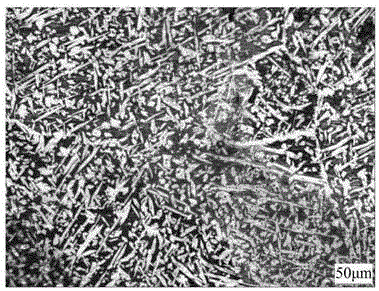

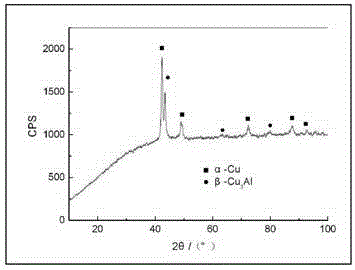

[0043] The raw materials are batched according to the mass percentage: Mn 5%, Al 6.5%, Fe2%, Zn2%, Ce0.6%, and the balance of Cu is smelted in a vacuum induction furnace. The melting temperature is 1230 ° C, and the temperature is kept for 10 minutes. Then, The alloy liquid with a pouring temperature of 1150 ° C was poured into a graphite mold with a diameter of 40 mm, and a circular ingot with a diameter of 40 mm was obtained by natural cooling; the alloy was β-Cu 3 Al single-phase solid solution structure, its microhardness, tensile strength and elongation values are shown in Table 2; its friction and wear properties are shown in Table 3.

Embodiment 2

[0045] The raw materials are batched by mass percentage: Mn 6%, Al 6%, Fe 1.5%, Zn 1.5%, Ce 0.4%, and the remainder Cu; smelted in a vacuum induction furnace, the smelting temperature is 1235 ° C, and the temperature is kept for 10 minutes; Then, pour the alloy liquid with a pouring temperature of 1155°C into a graphite mold with a diameter of 40mm, and naturally cool to obtain a circular ingot with a diameter of 40mm; the alloy is β-Cu 3 Al single-phase solid solution structure, its microhardness, tensile strength and elongation values are shown in Table 2; its friction and wear properties are shown in Table 3.

Embodiment 3

[0047] The raw materials are batched by mass percentage: Mn 6.5%, Al 6.5%, Fe 1.5%, Zn 1.5%, Ce 0.4%, and the balance Cu; smelted in a vacuum induction furnace, the smelting temperature is 1240 ° C, and the temperature is kept for 11 minutes; Then, pour the alloy liquid with a pouring temperature of 1160 ° C into a graphite mold with a diameter of 40 mm, and naturally cool to obtain a circular ingot with a diameter of 40 mm; the alloy is β-Cu 3 Al single-phase solid solution structure, its microhardness, tensile strength and elongation values are shown in Table 2; its friction and wear properties are shown in Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| microhardness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com