Patents

Literature

61results about How to "Good anti-friction and wear resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

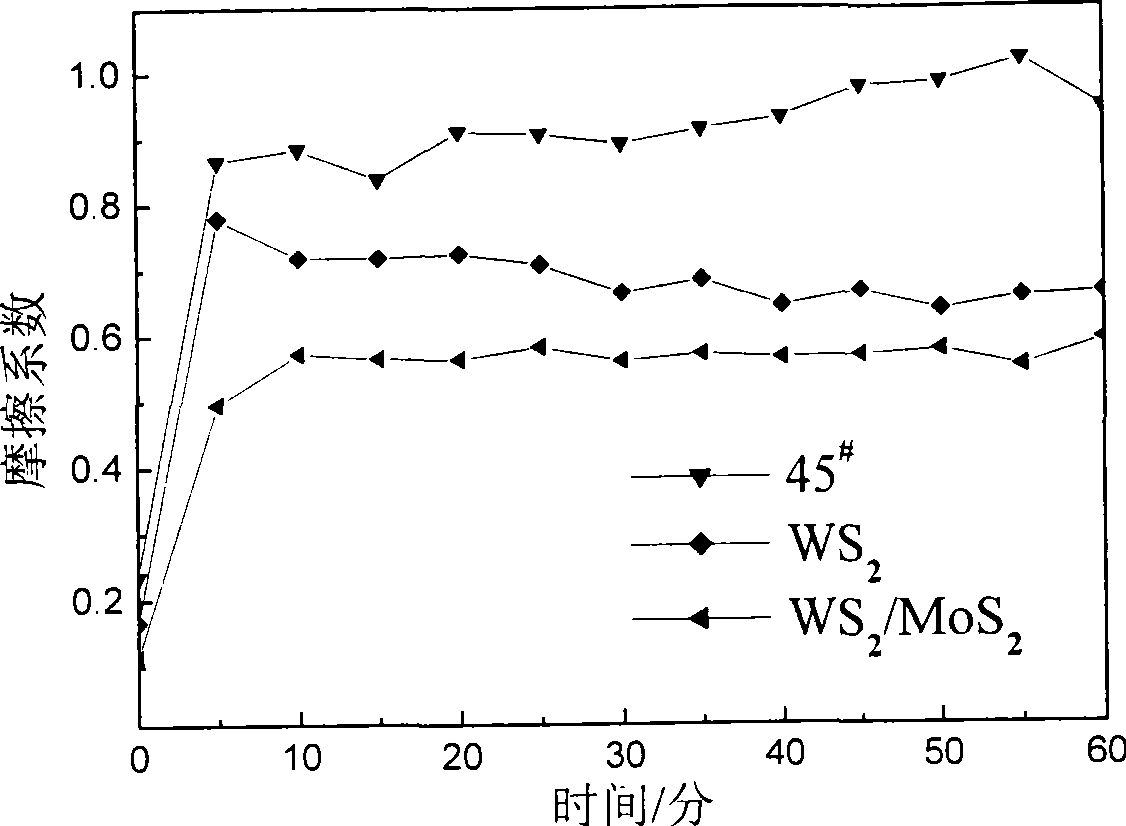

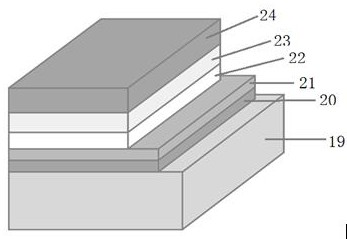

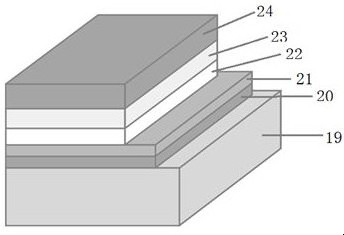

WS2/MoS2 solid lubrication multilayer film and method for making same

ActiveCN101398123AGood effectImprove mechanical propertiesLayered productsVacuum evaporation coatingSputteringSulfur

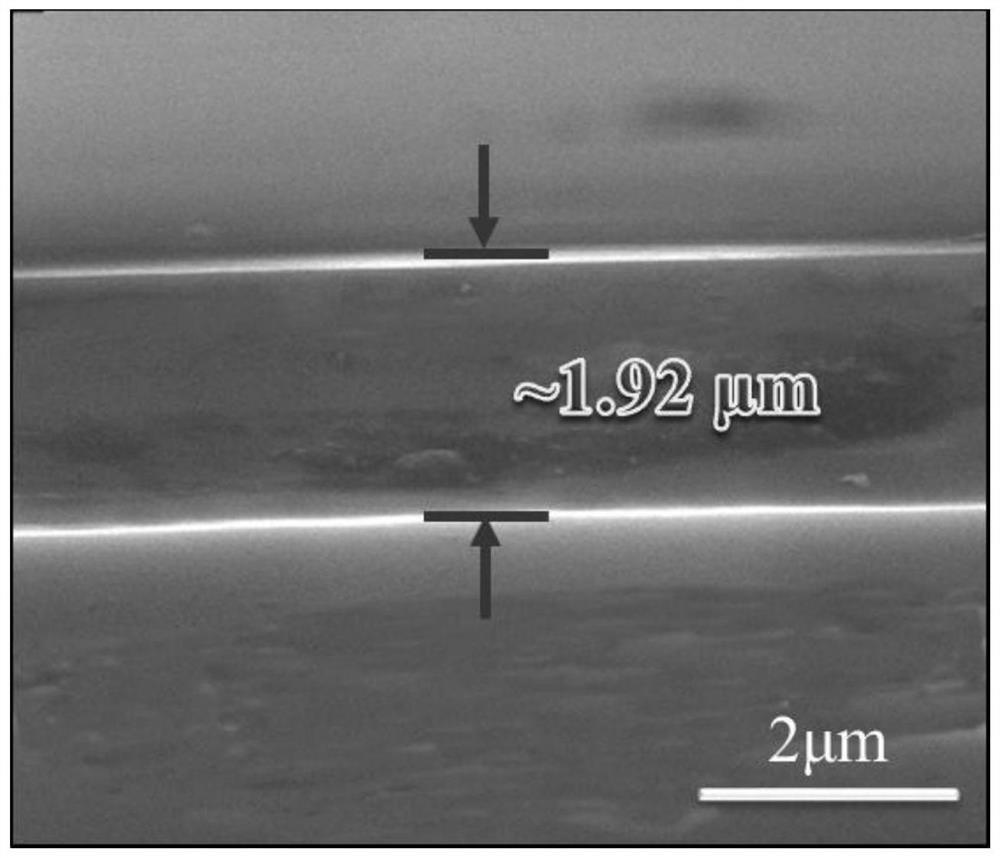

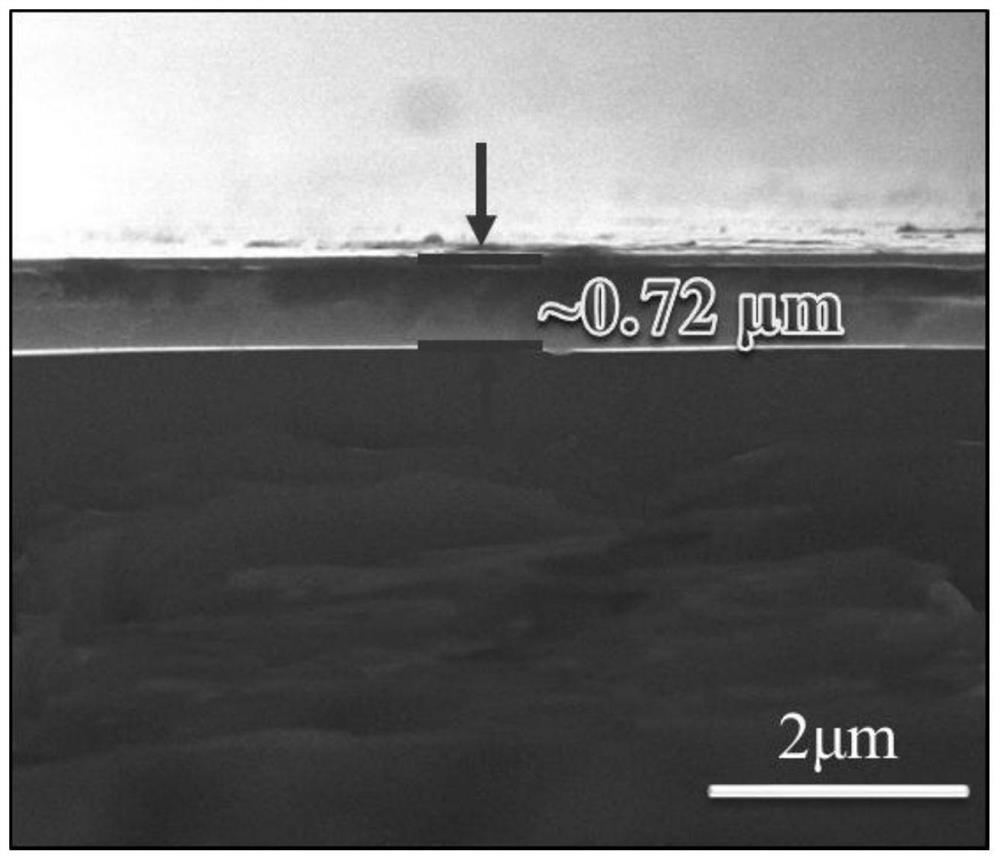

The invention provides a WS2 / MoS2 solid lubricating multilayer film and a preparation method thereof, which firstly prepares a W / Mo multilayer film through double-target RF sputtering and a W layer and an Mo layer are deposited alternatively on a substrate, and then low temperature ion sulfurizing is carried out to the W / Mo multilayer film and the WS2 / MoS2 solid lubricating multilayer film is prepared. The invention prepares a novel solid lubricating film, namely, the WS2 / MoS2 solid lubricating nano multilayer film through two-step compound treatment. The sublayers of the WS2 / MoS2 solid lubricating nano multilayer film have the same thickness and element sulfur is distributed evenly in the multilayer film, thus leading the multilayer film to have higher rigidity, good nano properties, elasticity modulus and yield strength, better practicability and excellent anti-friction and wear-resistant properties in nano mechanical properties and anti-friction and wear-resistant aspects as being compared with the existing nano multilayer films. The WS2 / MoS2 solid lubricating multilayer film can be used on various friction surfaces of machinery equipment, particularly on precisely matching surfaces to reduce friction and improve lubrication conditions.

Owner:ACADEMY OF ARMORED FORCES ENG PLA

Graphene modified teflon solid lubrication coating and preparation method thereof

InactiveCN105331210AGood self-lubricating performanceImprove mechanical propertiesCoatingsArray data structureEmulsion

The invention discloses a graphene modified teflon solid lubrication coating which is prepared from, by mass, 100 parts of teflon, 0.3-10 parts of molybdenum disulfide, 0-8 parts of graphite, 0.1-5 parts of grapheme, 0-6 parts of graphene oxide and 80-380 parts of water. A preparation method of the graphene modified teflon solid lubrication coating includes the steps that teflon emulsion, the molybdenum disulfide, the graphite, the grapheme, the graphene oxide and the balance water are mixed to be uniform and then sprayed on the surface of a metal product in a coating mode, then high-temperature sintering and cooling are conducted, and the graphene modified teflon solid lubrication coating can be obtained. The obtained graphene modified teflon solid lubrication coating has good self-lubricating performance, mechanical properties, wear reduction and resistance, heat stability and adhesion.

Owner:JIANGSU YOUCHENG POLYMER MATERIALS SCI & TECH CO LTD

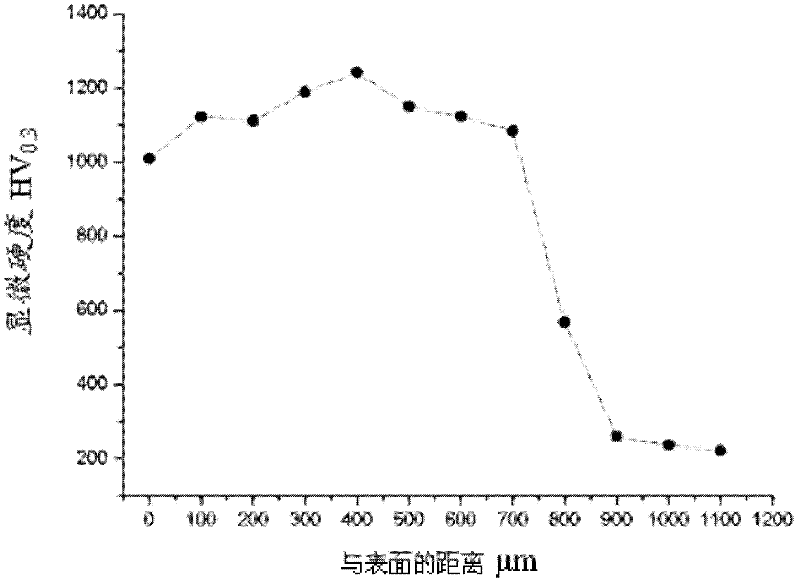

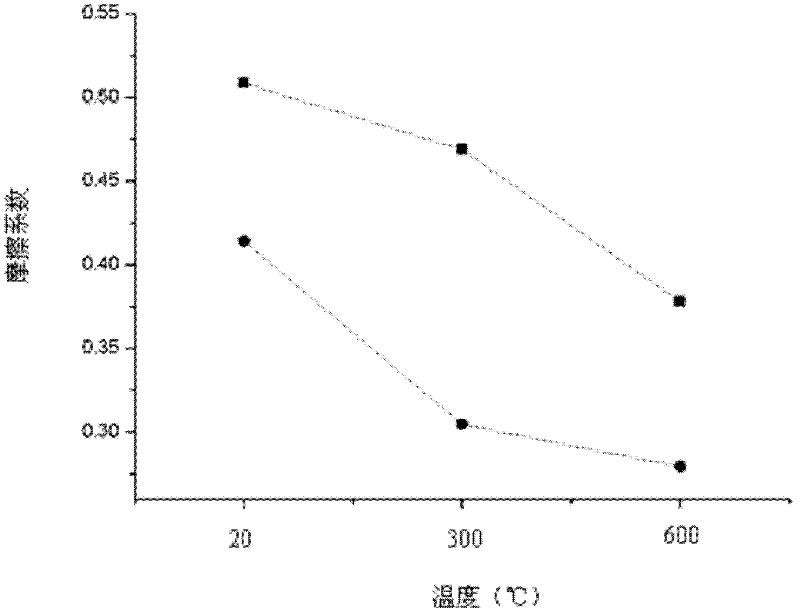

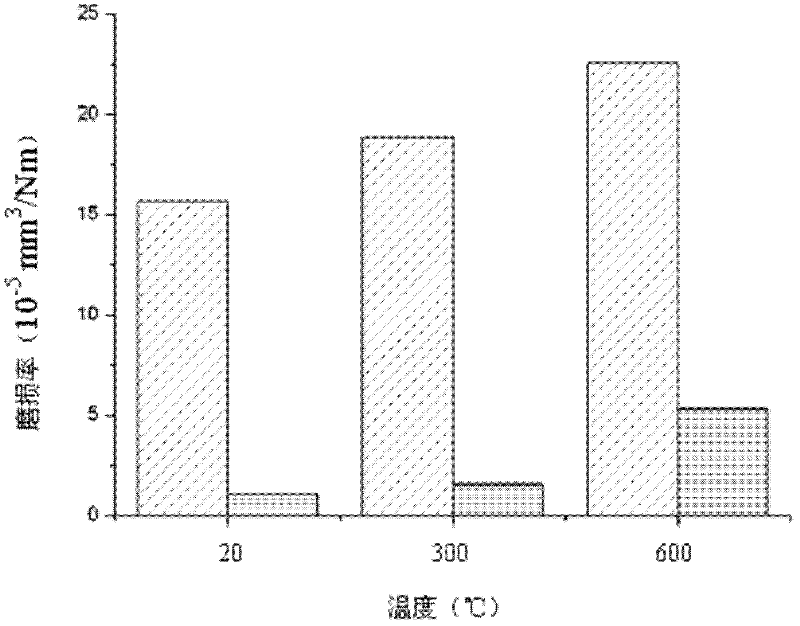

Coating material and preparation method thereof

ActiveCN102505091ADense tissueReduce porosityMetallic material coating processesChromium carbideWear resistant

The invention relates to the alloy field, and particularly relates to a coating material and a preparation method thereof. The coating material comprises the following raw materials: 14-17.5 parts by weight of nickel, 3-3.5 parts by weight of chromium, 49-52.5 parts by weight of chromium carbide, 25-30 parts by weight of tungsten disulfide. The coating material prepared by laser cladding has good antifriction wear resistant performance at room temperature (20 DEG C) to 600 DEG C, and can effectively increase the antifriction wear resistant performance of a substrate at a high temperature.

Owner:SUZHOU UNIV

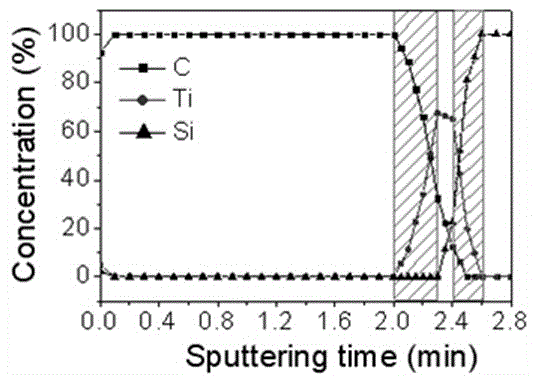

Method for preparing titanium/diamond-like nanometer multilayer film on silicon surface

InactiveCN105132878AHigh bonding strengthReduce interface stressVacuum evaporation coatingSputtering coatingComposite filmVacuum chamber

The invention discloses a method for preparing a titanium / diamond-like nanometer multilayer film on a silicon surface. The method concretely comprises the following steps of: drying a monocrystalline silicon substrate subjected to chemical cleaning in advance; putting the dried monocrystalline silicon substrate onto a rotating sample table of a cathode arcing device; performing vacuum pumping; introducing argon gas into a vacuum chamber; performing sputtering cleaning on the surface of the silicon substrate through an ion source; using high-purity metal titanium and graphite as targets, and using a direct current and pulse double-excitation-source cathode plasma discharge technology for respectively preparing a titanium nanometer function layer and a diamond-like film; and performing later-stage vacuum annealing treatment according to needs. The method has the advantages that the preparing process is simple; and the method can be used for preparing the diamond-like nanometer multilayer composite film with different surface structures. The titanium / diamond-like nanometer multilayer film prepared by the method provided by the invention has the advantages of high hardness, low stress and friction-reduction and abrasion-resistant performance.

Owner:TAIYUAN UNIV OF TECH

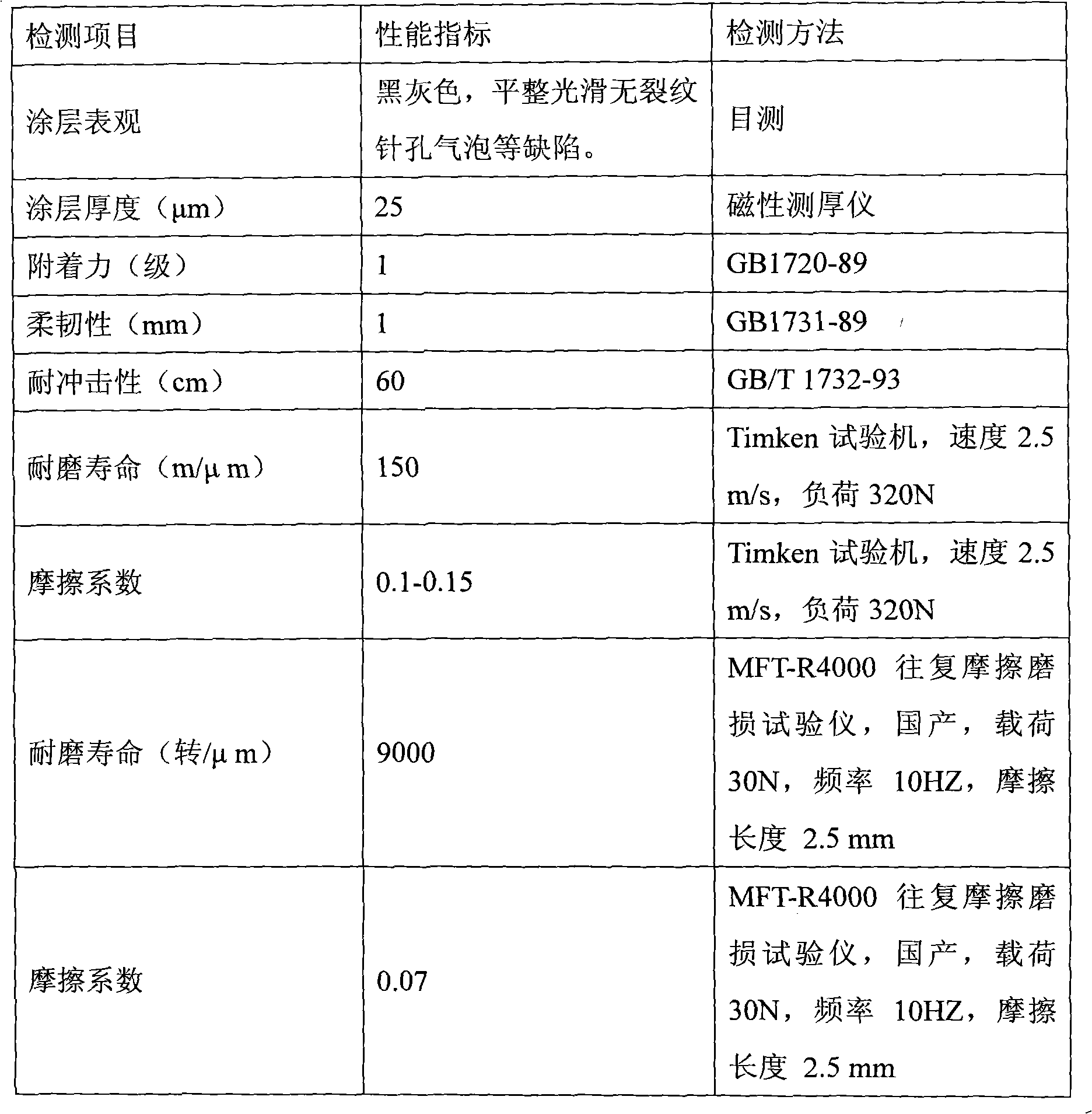

Aqueous epoxy adhering solid lubricant

The invention discloses an aqueous epoxy adhering solid lubricant. The lubricant is composed of bi-component aqueous epoxy resins, a solid lubricant, a wear-resisting agent, a surface active agent, an antiseptic agent, an anti-sedimentation agent and water. The lubricant can be coated on the surfaces of processing workpieces such as stainless steel, carbon steel, alloy and the like. The lubricant is characterized in that water is adopted as a solvent, which has no pollution and no damage on bodies of painting constructors; and the coating has the advantages of good antifriction property and excellent physicochemical properties, and can replace an organic solvent type solid lubricant to be used on slide parts of multiple mechanical devices.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

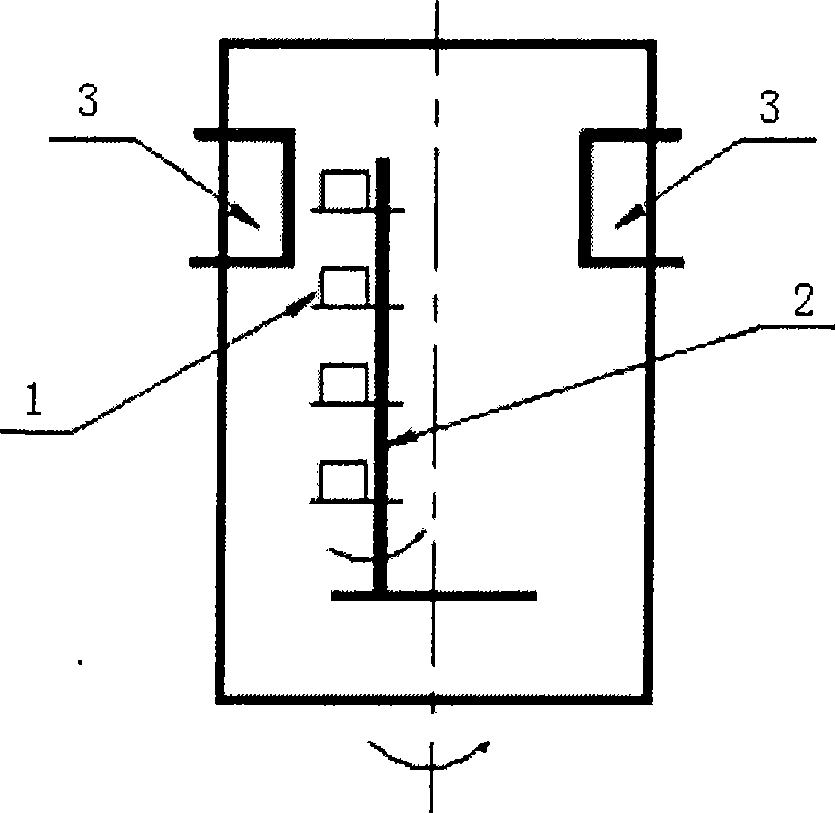

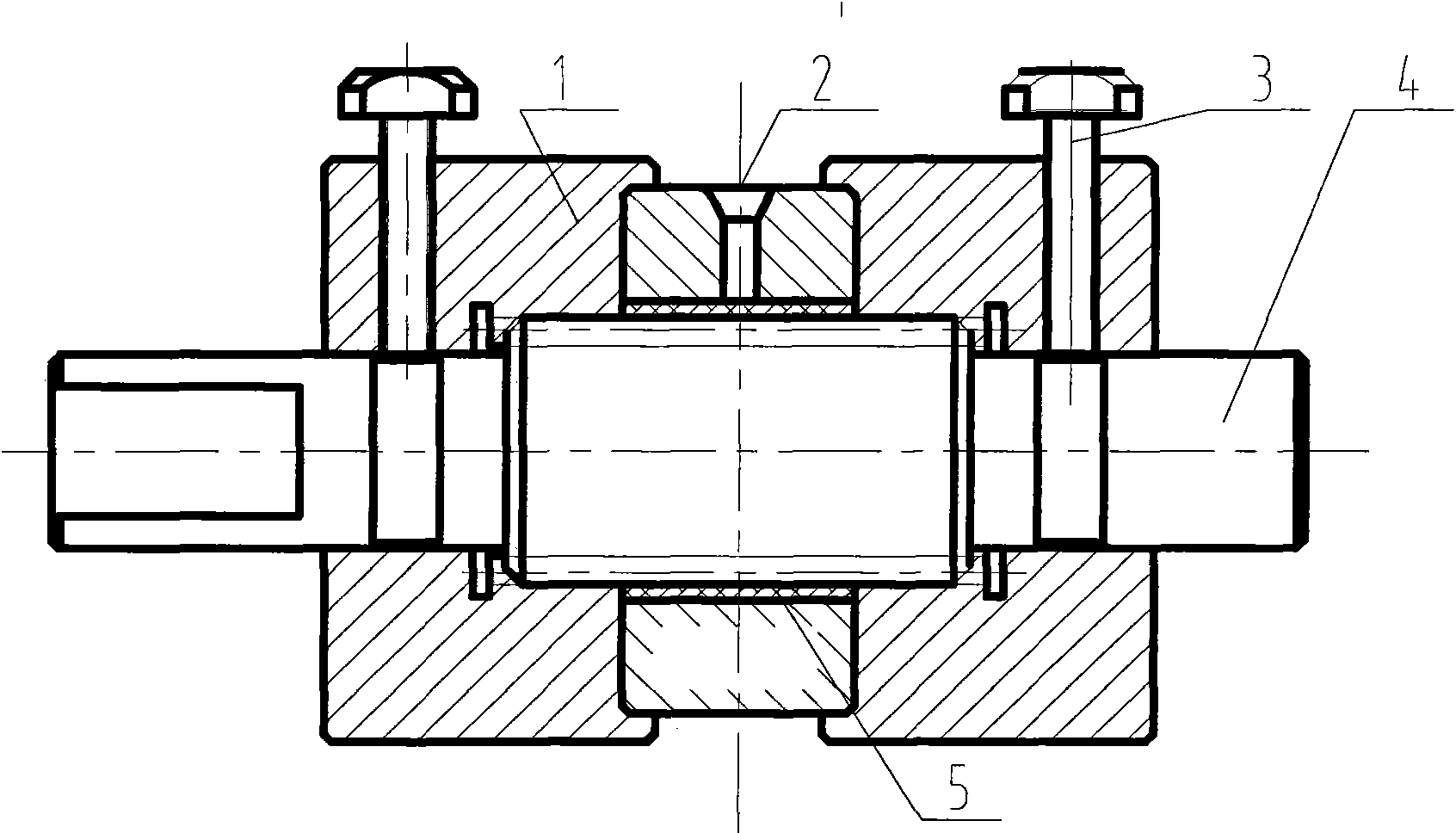

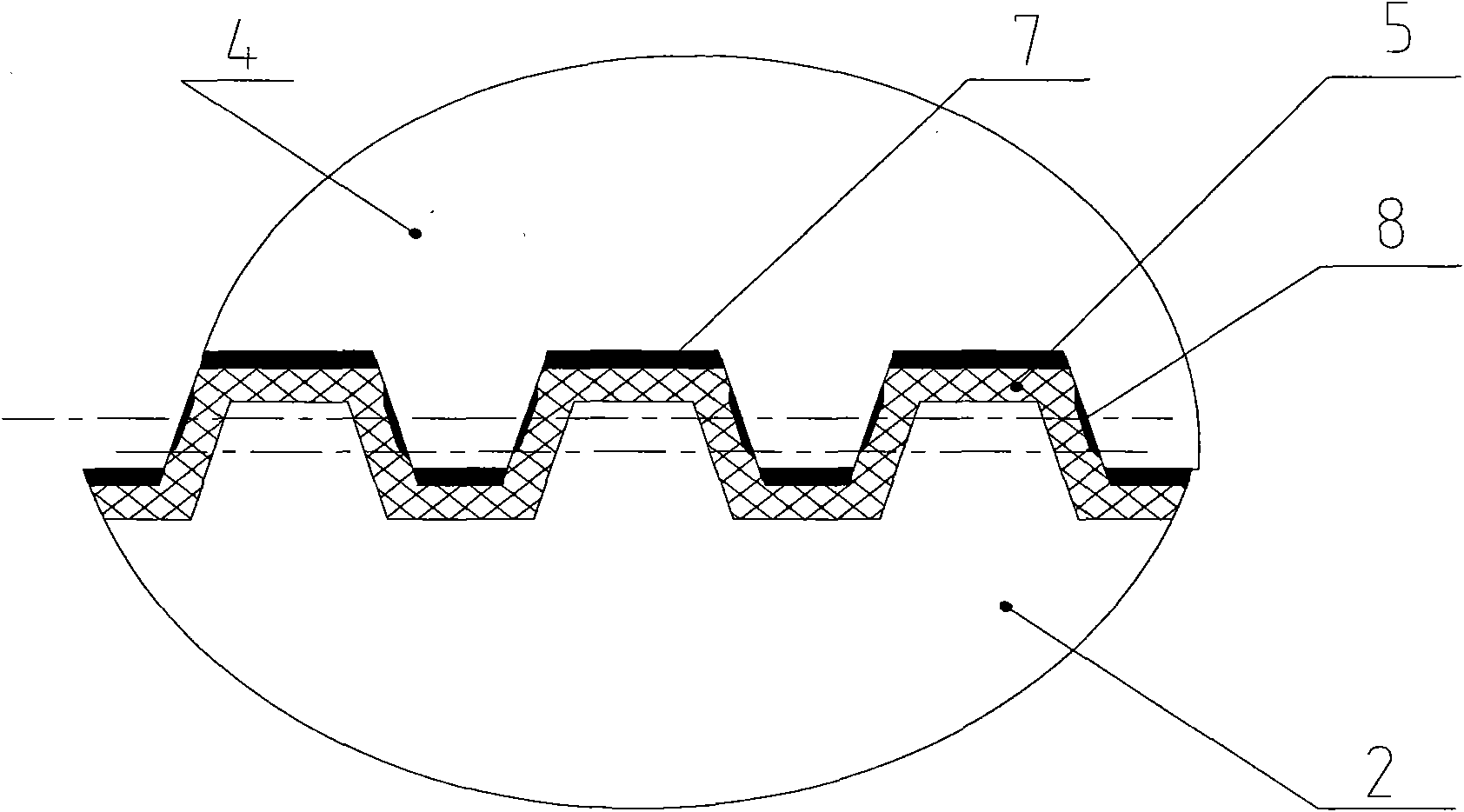

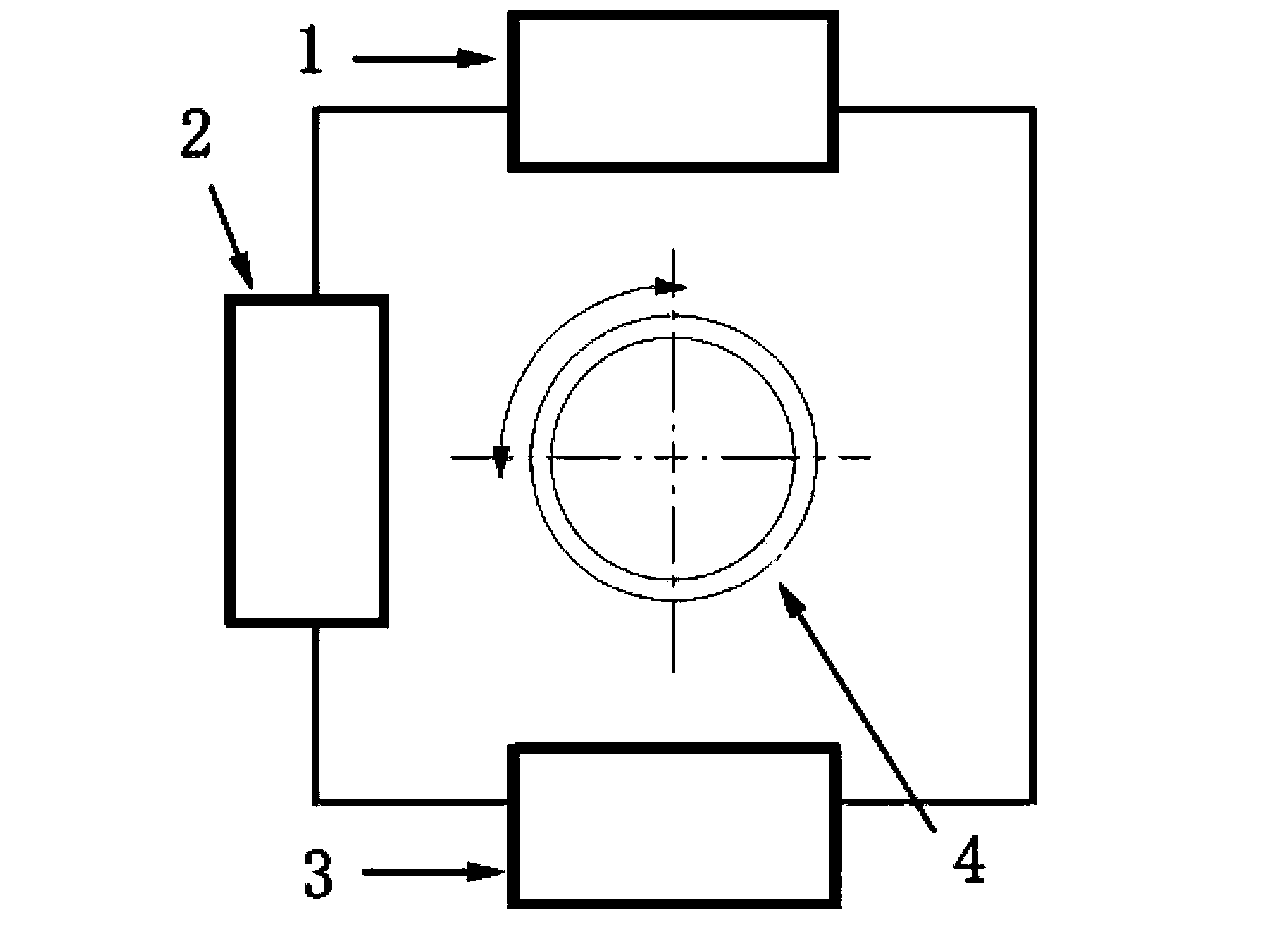

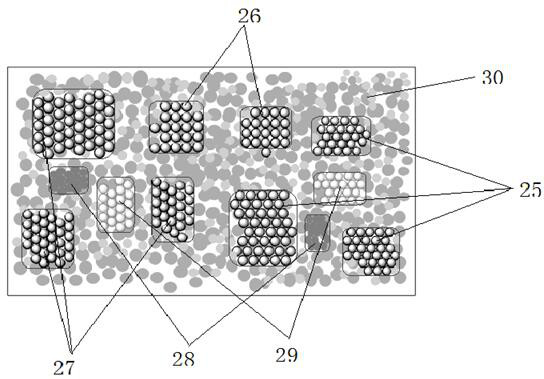

Injection moulding-based high-efficiency heavy-duty transmission nut material, method and device

The invention discloses a carbon fiber-reinforced self-lubricating composite material and a method and a device for manufacturing steel backing self-lubricating composite material transmission nuts through injection moulding of the material. The self-lubricating composite material consists of epoxy resin, carbon fiber and various fillers and modified substances. The composite material forms a self-lubricating lining on the surface of a steel nut substrate in an injection moulding mode. The injection moulding device comprises a substrate nut (2), a process screw rod (4) screwed into the substrate nut (2), and two positioning nuts (1). A gap between 1 and 2mm is reserved between the substrate nut (2) and the process screw rod (4) and is uniformly distributed in the axial direction, the peripheral direction and the radial direction. Before the injection, a lubricating oil way with proper thickness is formed by adhereing an adhesive tape or drawing through paraffin on the surface of the process screw rod (4); the composite material is injected into the injection moulding device through a charging barrel; and after the injection is finished and the lining is completely cured, the positioning nuts (1) are disassembled, the transmission nut (2) manufactured is screwed out of the process crew rod (4), residues in the lubricating oil way are removed, and the required transmission nut (2) is obtained. The novel nut has the advantages of high bearing capacity, small friction coefficient and good dynamic performance.

Owner:GUANGDONG UNIV OF TECH

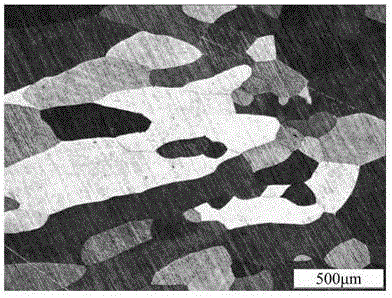

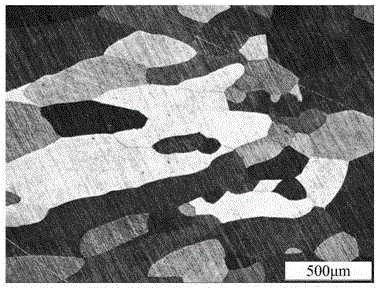

High-performance antifriction and antiwear manganese-aluminum-bronze alloy

The invention relates to a high-performance antifriction and antiwear manganese-aluminum-bronze alloy. According to the technical scheme adopted by the invention, the high-performance antifriction and antiwear manganese-aluminum-bronze alloy is prepared from Mn, Al, Fe, Zn, Ce and Cu by casting and hot forging or hot rolling. The elements of the high-performance antifriction and antiwear manganese-aluminum-bronze alloy comprise 5-10% by mass of Mn, 6-10% by mass of Al, 1.5-2.5% by mass of Fe, 1.5-2.5% by mass of Zn, 0.4-0.8% by mass of Ce and the balance of Cu. The high-performance antifriction and antiwear manganese-aluminum-bronze alloy provided by the invention can be used for overcoming the defects of low fatigue strength and poor heat resistance of babbitt and increase of seizure resistance, compliance resistance and embedment resistance of copper-based alloy and aluminum-based alloy in poor lubrication environment and solving the traditional problem in the field that toxic metals such as lead and cadmium can cause pollution to environment easily. In addition, the high-performance antifriction and antiwear manganese-aluminum-bronze alloy can function as the antifriction and antiwear material of all parts and components of a friction motion pair used in complex conditions of high speed, heavy duty, high temperature and corrosive media in the machinery industry, metallurgy industry, energy industry and chemical industry and can be used for preparing parts and components such as sliding bearings, worm gears, sliding blocks, shaft sleeves and driving nuts.

Owner:HUNAN UNIV OF SCI & TECH

Aluminium nitride-based multi-element nano-composite ceramic die material and preparation method thereof

The invention discloses an aluminium nitride-based multi-element nano-composite ceramic die material and a preparation method thereof. The material comprises the following raw materials in parts by weight: 60-80 parts of aluminium nitride, 10-20 parts of aluminium carbide, 15-25 parts of silicon boride, 2-6 parts of scandium oxide, 4-8 parts of neodymium oxide, 2-4 parts of chromium, 1-3 parts of tungsten and 1-3 parts of nickel, wherein nanoscale powder of all the materials is adopted; the grain size of aluminium nitride is 10-100 nanometers; the grain sizes of aluminium carbide and silicon boride are 1-10 nanometers; the grain sizes of the other raw materials are 1-100 nanometers. The preparation method is characterized by using aluminium nitride as the matrix, adding aluminium carbide and silicon boride as reinforcing phases, scandium oxide and neodymium oxide as stabilizing agents and chromium, tungsten and nickel as sintering aids and carrying out hot pressed sintering on the materials, thus preparing the material. A die has strong ageing and defect resistance, good comprehensive mechanical properties and excellent antifriction and wear resistance properties.

Owner:辽宁跨克石油装备有限公司

Aluminum oxide-based nano-composite ceramic mold material and preparation method thereof

InactiveCN107445636AImprove mechanical propertiesAvoid growing upComposite ceramicUltrasonic dispersion

The invention provides an aluminum oxide-based nano-composite ceramic mold material and a preparation method thereof. The composite material is prepared from the raw materials: aluminum oxide, lecithin, silicon carbide, calcium sulfate whiskers, zirconium oxide, titanium oxide, zinc oxide, molybdenum, magnesium oxide and 1 to 3 parts of nickel. The preparation method comprises the steps of adding the aluminum oxide into absolute ethyl alcohol to prepare into suspension liquid A; adding the lecithin, the silicon carbide, the calcium sulfate whiskers, the zirconium oxide, the titanium oxide and the zinc oxide into the absolute ethyl alcohol to prepare into suspension liquid B; mixing the suspension liquid A and the suspension liquid B, adding the molybdenum, the magnesium oxide and the nickel, and carrying out ultrasonic dispersion; pouring the mixed suspension liquid into a ball-milling tank; utilizing a sintered carbide ball for mechanically ball-milling, vacuum drying the grinding liquid at 100 DEG C, sieving the obtained composite powder, and performing hot pressed sintering to obtain the aluminum oxide-based nano-composite ceramic mold material. Compared with an aluminum oxide ceramic mold material, the composite ceramic mold material provided by the invention has better integrated mechanical property and excellent antifriction and anti-wear properties.

Owner:SUZHOU HAOYAN PRECISION MOLD CO LTD

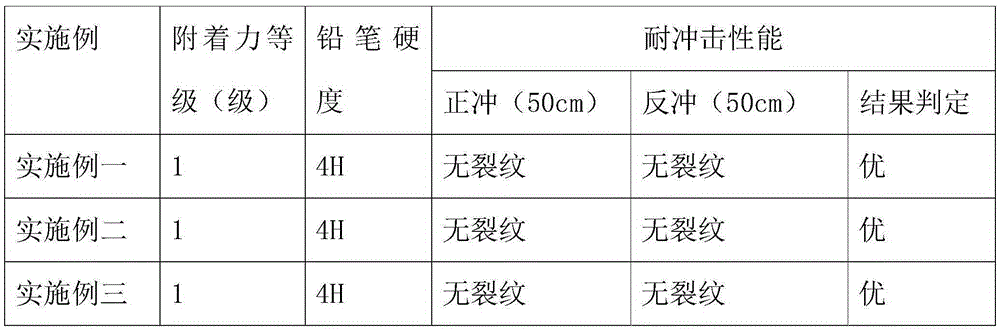

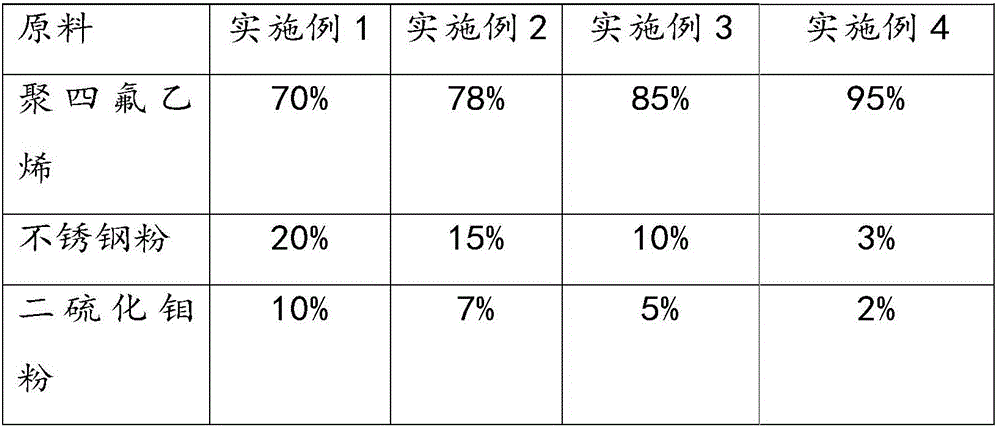

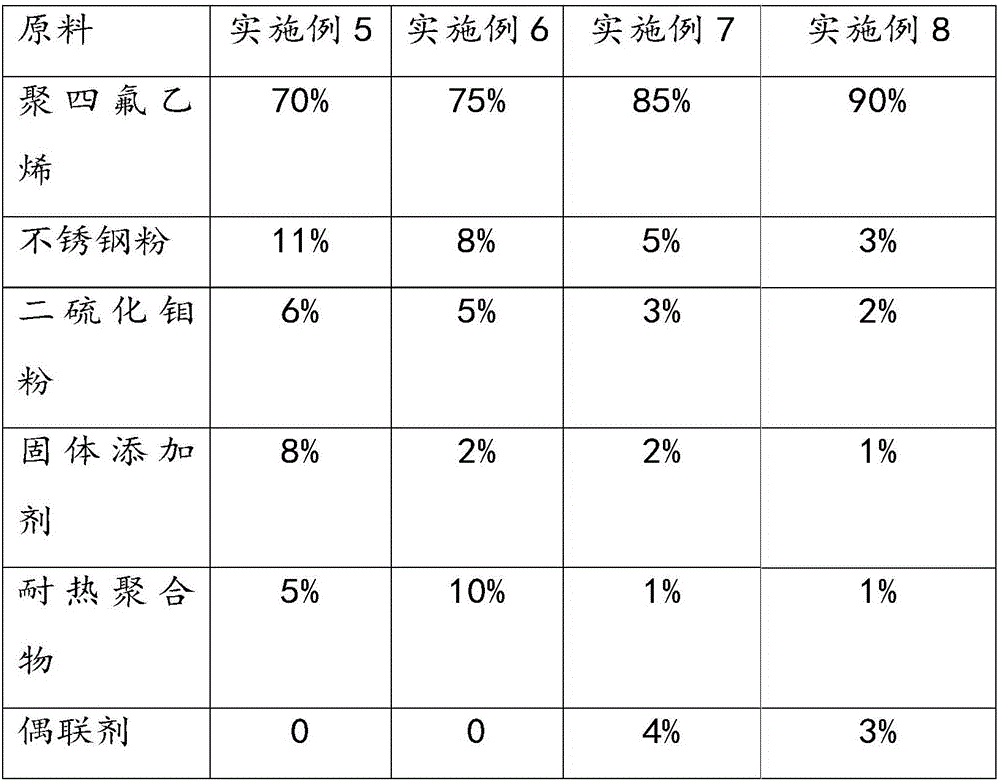

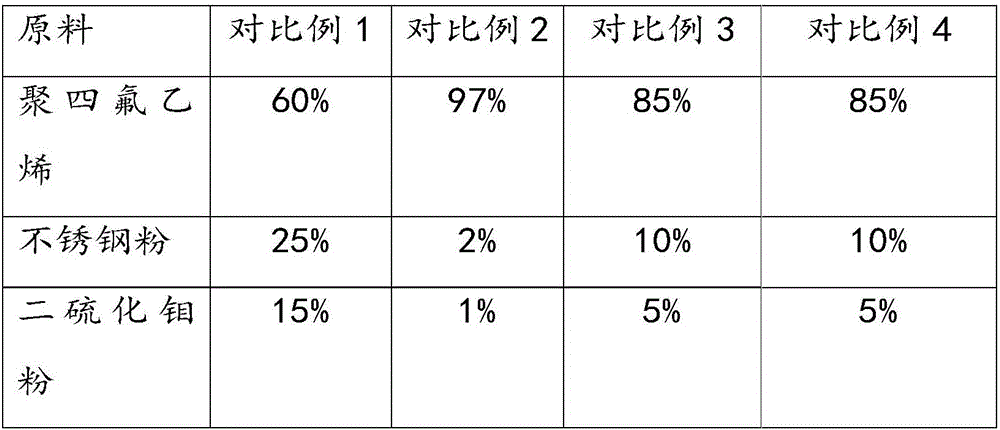

Filled modified polytetrafluoroethylene material as well as application and preparation method thereof

ActiveCN107177145AGood anti-friction and wear resistanceGood dimensional stabilityDomestic articlesWear resistanceUltimate tensile strength

The invention belongs to the technical field of polytetrafluoroethylene materials and particularly relates to a filled modified polytetrafluoroethylene material as well as application and a preparation method thereof. By taking stainless steel powder as a filler, the filled modified polytetrafluoroethylene material provided by the invention is prepared from the following raw materials in percentage by weight: 70-95 percent of polytetrafluoroethylene, 3-20 percent of the stainless steel powder and 2-10 percent of molybdenum disulfide powder. The invention also provides the application of the filled modified polytetrafluoroethylene material in the aspect of preparing a sealing piece. The filled modified polytetrafluoroethylene material has good self-lubricity, wear resistance and size stability, is good in smooth finish, liable to process, excellent in corrosion resistance performance and high and low temperature resistance performance, high in mechanical strength, wide in temperature range and good in heat conductivity, is very liable to transfer heat outsides particularly under the high temperature working condition, can keep the size of a product stable without easiness in deformation, and thus the antifriction and wear resistance performance of the product are greatly improved, and the service life of the product is greatly prolonged.

Owner:BENCI HUARIF MACROMOLECULE MATERIAL MFG CO LTD

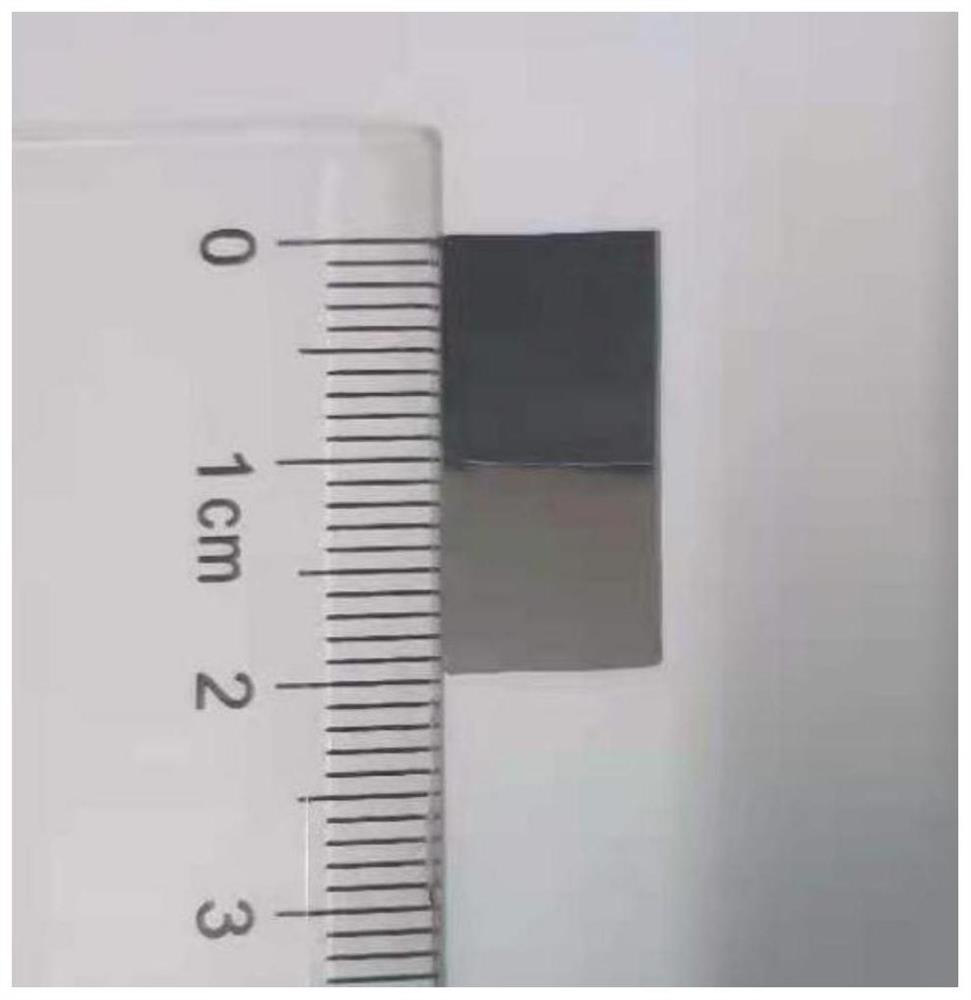

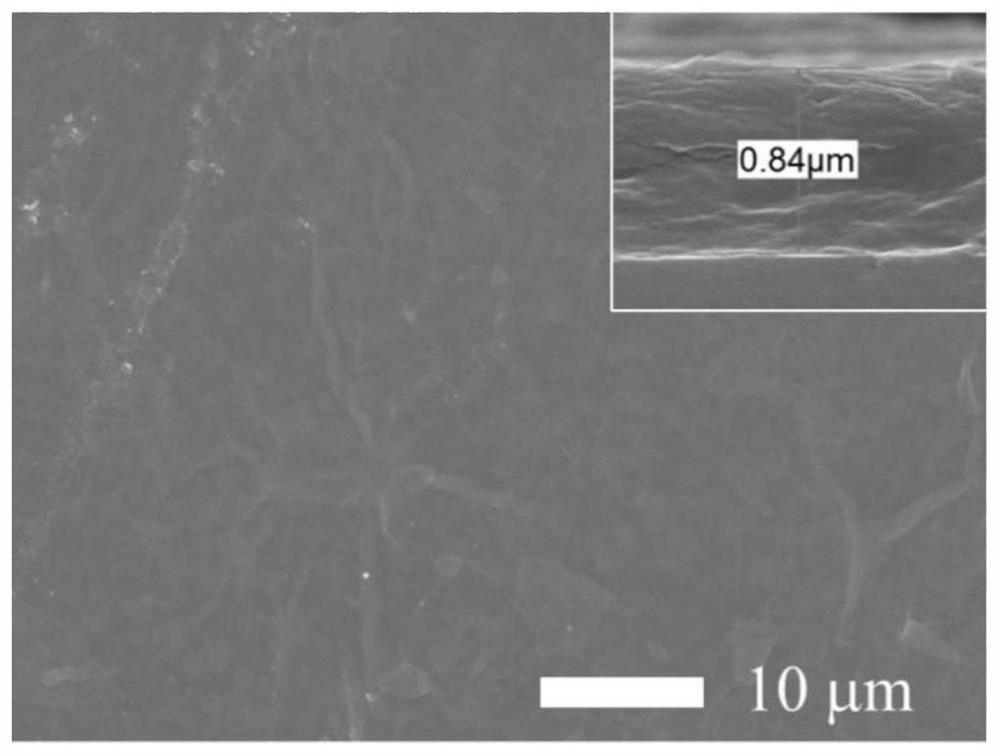

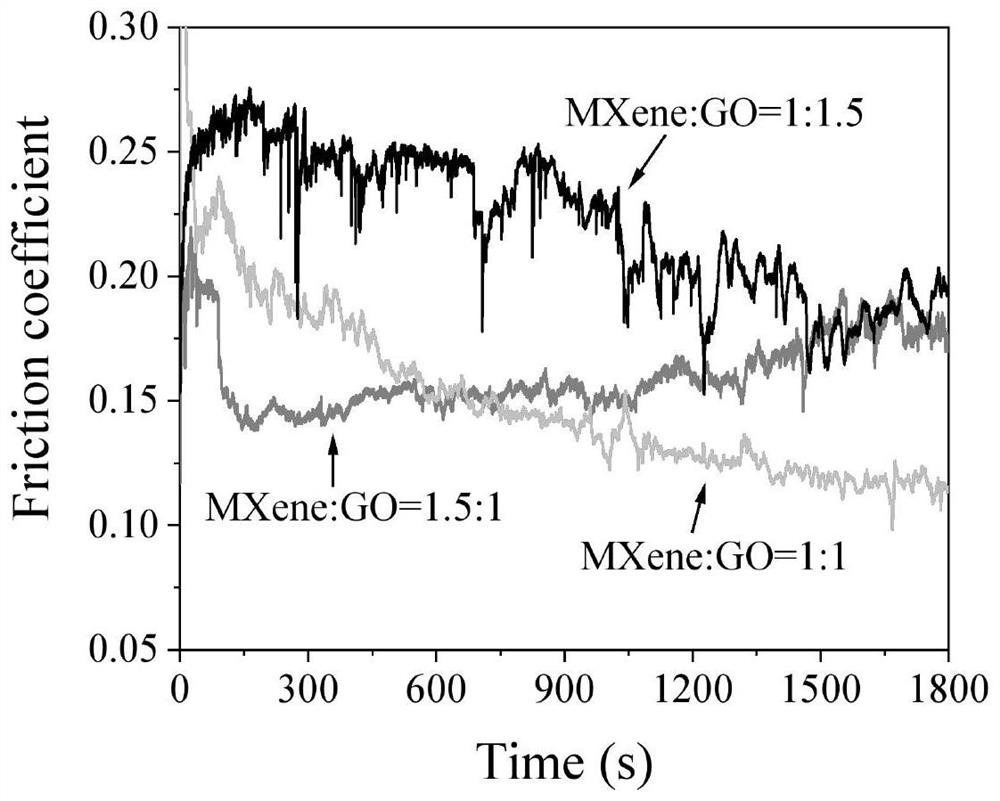

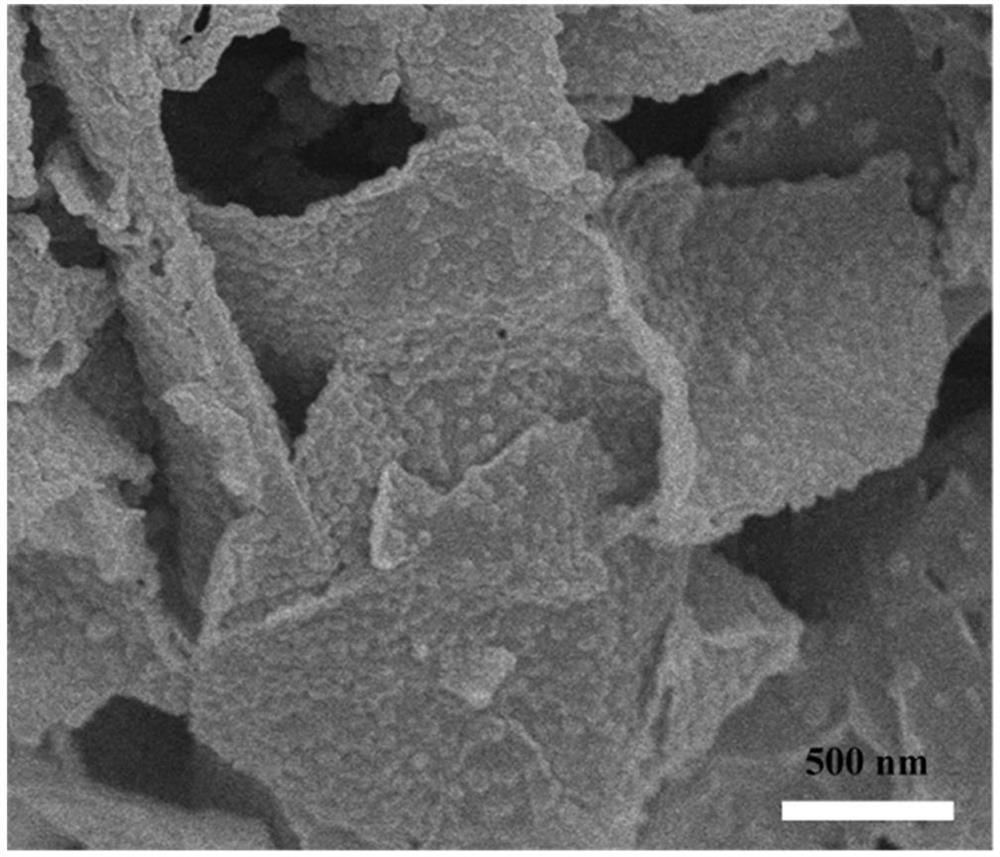

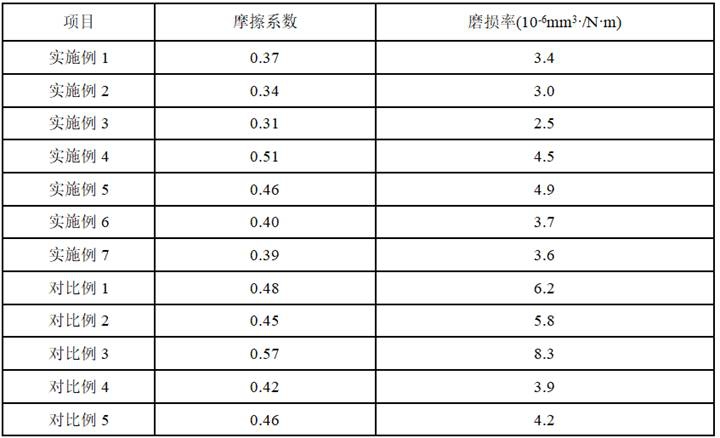

MXene/GO composite coating and preparation method and application thereof

PendingCN113355718AUniform surfaceThickness is easy to controlElectrophoretic coatingsElectrophoresisNanocomposite

The invention provides an MXene / GO composite coating and a preparation method and application thereof, and belongs to the technical field of nano composite materials. The preparation method comprises the following steps that MXene and graphene oxide are dispersed in water to obtain an MXene / GO mixed solution; electrophoretic deposition is carried out by taking polar plates as a cathode and an anode and the MXene / GO mixed solution as a deposition medium to obtain a deposition coating; and the deposition coating is dried, and the MXene / GO composite coating is obtained. According to the method for rapidly and simply preparing the MXene / GO composite coating, the MXene / GO composite coating prepared through the electrophoretic deposition method is uniform and flat in surface and controllable in thickness, meanwhile, under the action of an electric field, combination of negatively charged MXene and GO and the polar plates is firmer, excellent antifriction and abrasion resistance is shown, and the high-quality composite coating can be rapidly obtained.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI +1

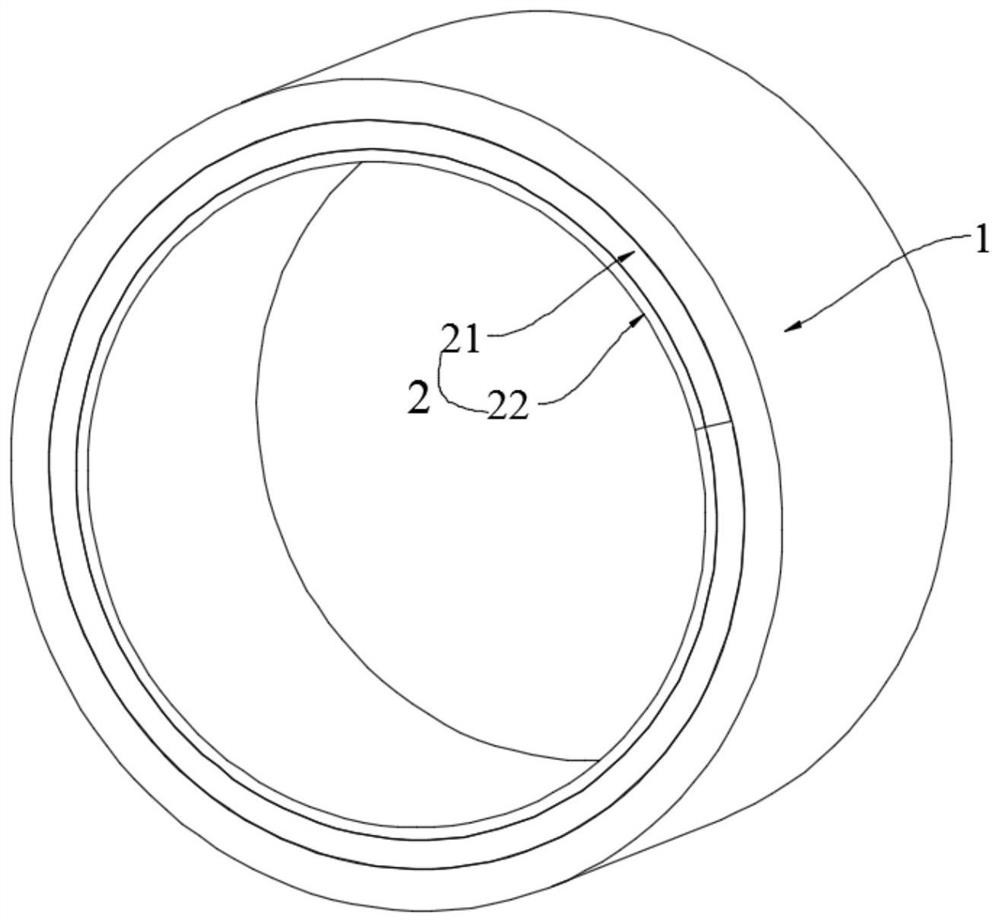

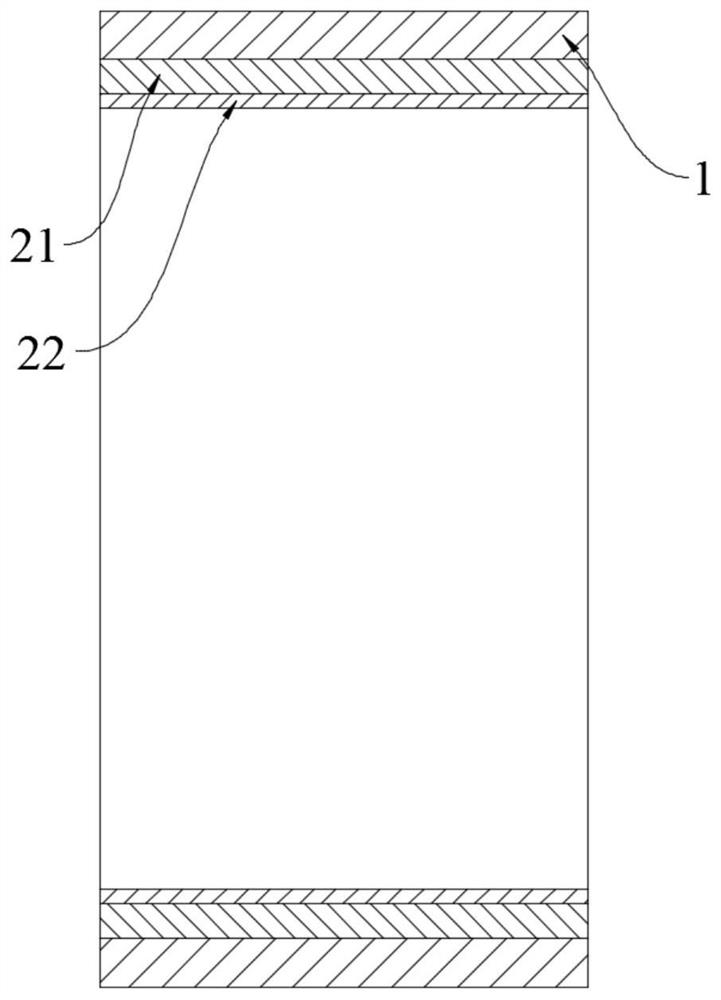

Self-lubricating bearing based on fiber fabric modification and manufacturing method thereof

The invention discloses a self-lubricating bearing based on fiber fabric modification and a manufacturing method thereof. The self-lubricating bearing comprises an outer lining and an inner lining layer installed in the outer lining, and the inner lining layer comprises a metal substrate and a fiber resin composite layer located on the metal substrate. The preparation method comprises the following steps that the fiber fabric treated by a silane coupling agent and an epoxy resin-based composite material are dipped at first to obtain a fiber fabric composite material, and the two steps of prepressing thermocuring and thermocuring are executed on the fiber fabric composite material and the metal substrate to obtain a planar dry friction self-lubricating composite material; and the planar dryfriction self-lubricating composite material is rolled into the shaft sleeve lining layer to be mounted in the outer lining, and accordingly the self-lubricating bearing can be obtained. The dry friction self-lubricating bearing is good in bearing capacity, the friction coefficient is effectively reduced, and the self-lubricating performance is remarkably improved.

Owner:WUHAN UNIV OF TECH

Zirconia-based micro-nano composite ceramic material

The invention discloses a zirconia-based micro-nano composite ceramic material. The zirconia-based micro-nano composite ceramic material comprises raw materials in parts by weight as follows: 60-80 parts of zirconia, 30-50 parts of aluminum nitride, 10-15 parts of titanium carbide, 10-15 parts of titanium nitride, 8-15 parts of zirconium carbide, 4-8 parts of neodymium oxide, 3-5 parts of magnesium oxide, 3-5 parts of aluminum hydroxide, 1-3 parts of chromium and 2-6 parts of nickel. All the raw materials adopt nanoscale powder. The zirconia-based micro-nano composite ceramic material has high ageing resistance, good combined mechanical properties and excellent antifriction and wear-resisting performance, and the combination property of a mold material is improved.

Owner:QINGDAO HONGYU ENVIRONMENTAL PROTECTION AIR CONDITIONING EQUIP

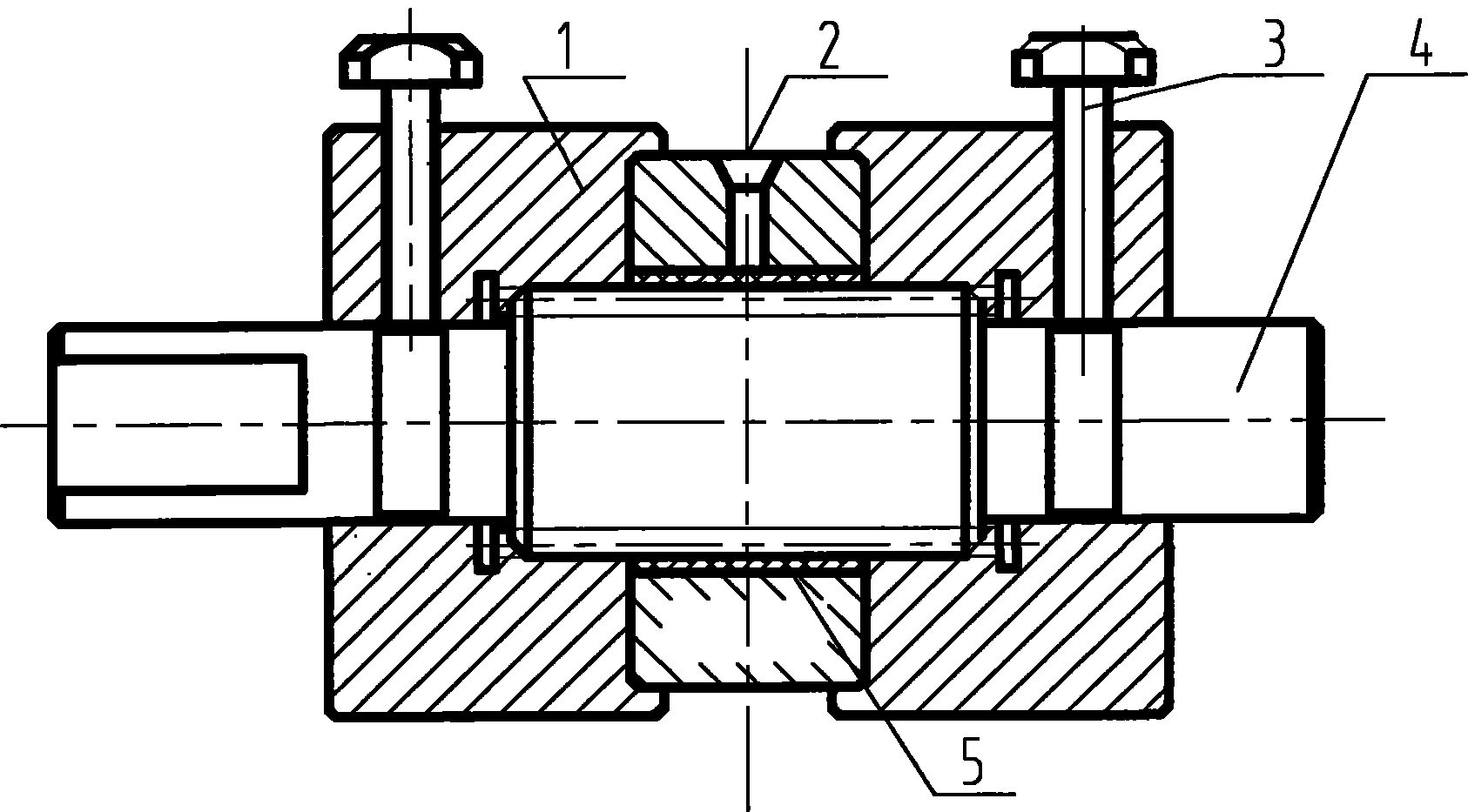

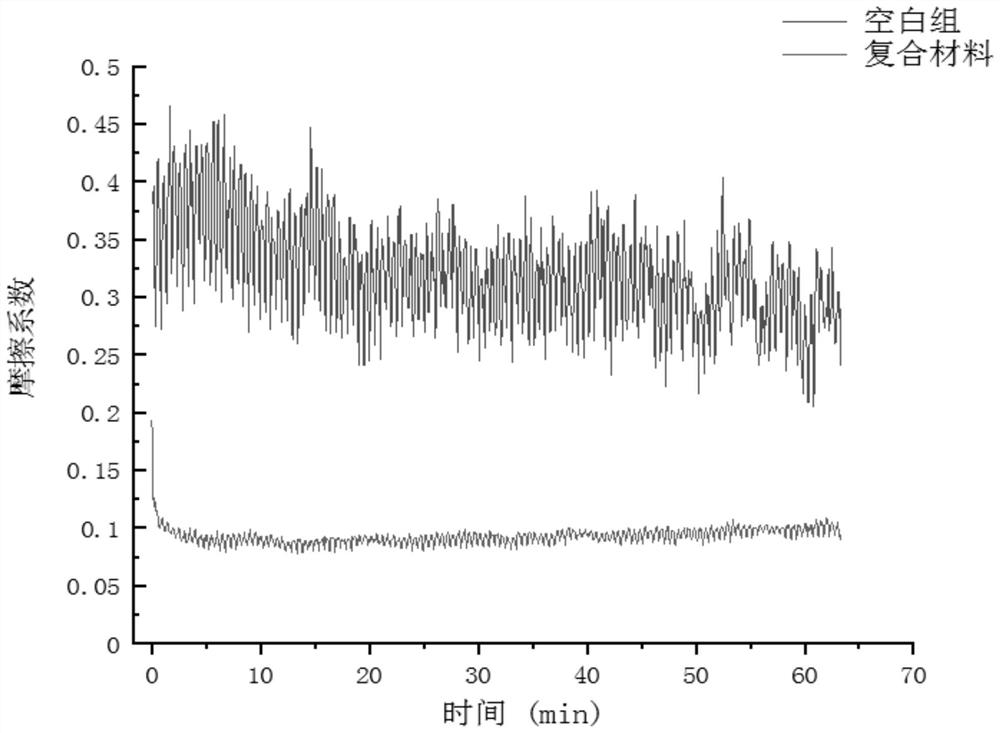

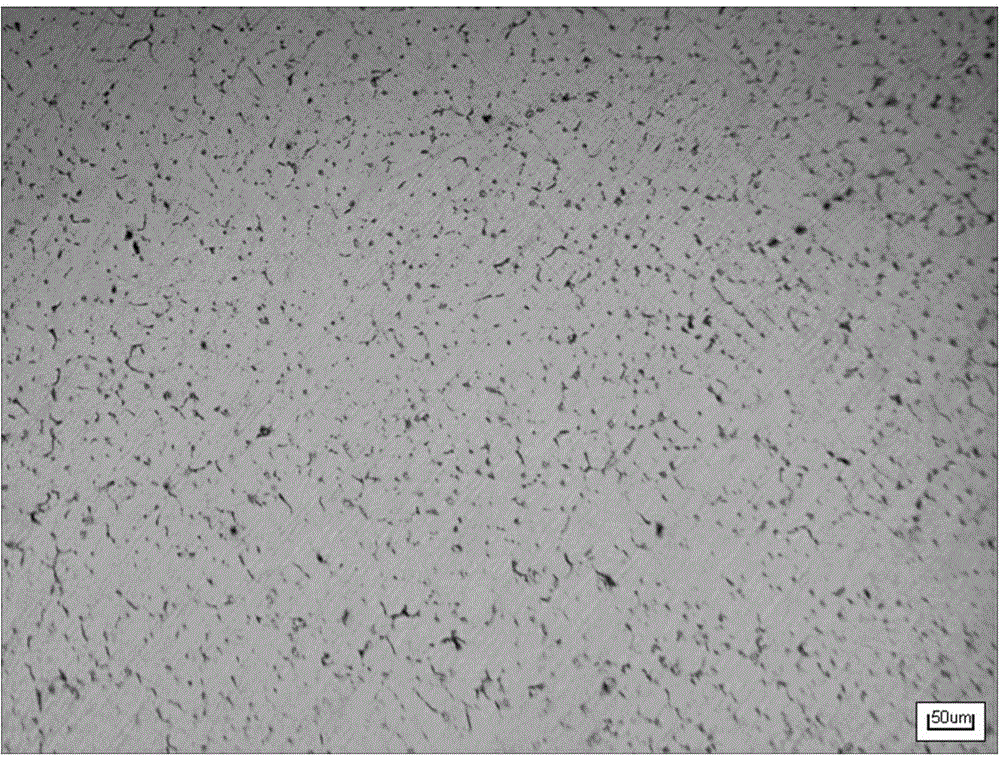

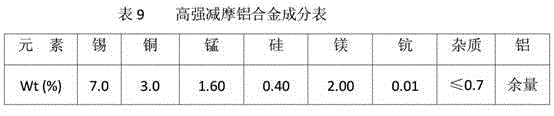

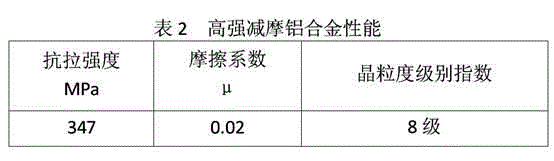

High-strength antifriction aluminum alloy

ActiveCN104561706AHigh strengthInhibition of recrystallizationRare-earth elementChemical composition

The invention discloses a high-strength antifriction aluminum alloy which comprises the following chemical components in percentage by weight: 1.0-7.0% of tin, 3.0-7.0% of copper, 0.20-1.60% of manganese, 0.40-1.60% of silicon, 0.40-2.0% of magnesium, 0.01-1.0% of rare earth element scandium, at most 0.70% of impurities and the balance of aluminum. The aluminum alloy has the advantages of uniform and segregation-free components, fine structure and high tensile strength (up to 320-350 MPa). The friction factor is less than 0.02, and the aluminum alloy has excellent antifriction property and wear resistance. The aluminum alloy has the advantages of favorable processability and low cost.

Owner:安徽熠辉新材料有限公司

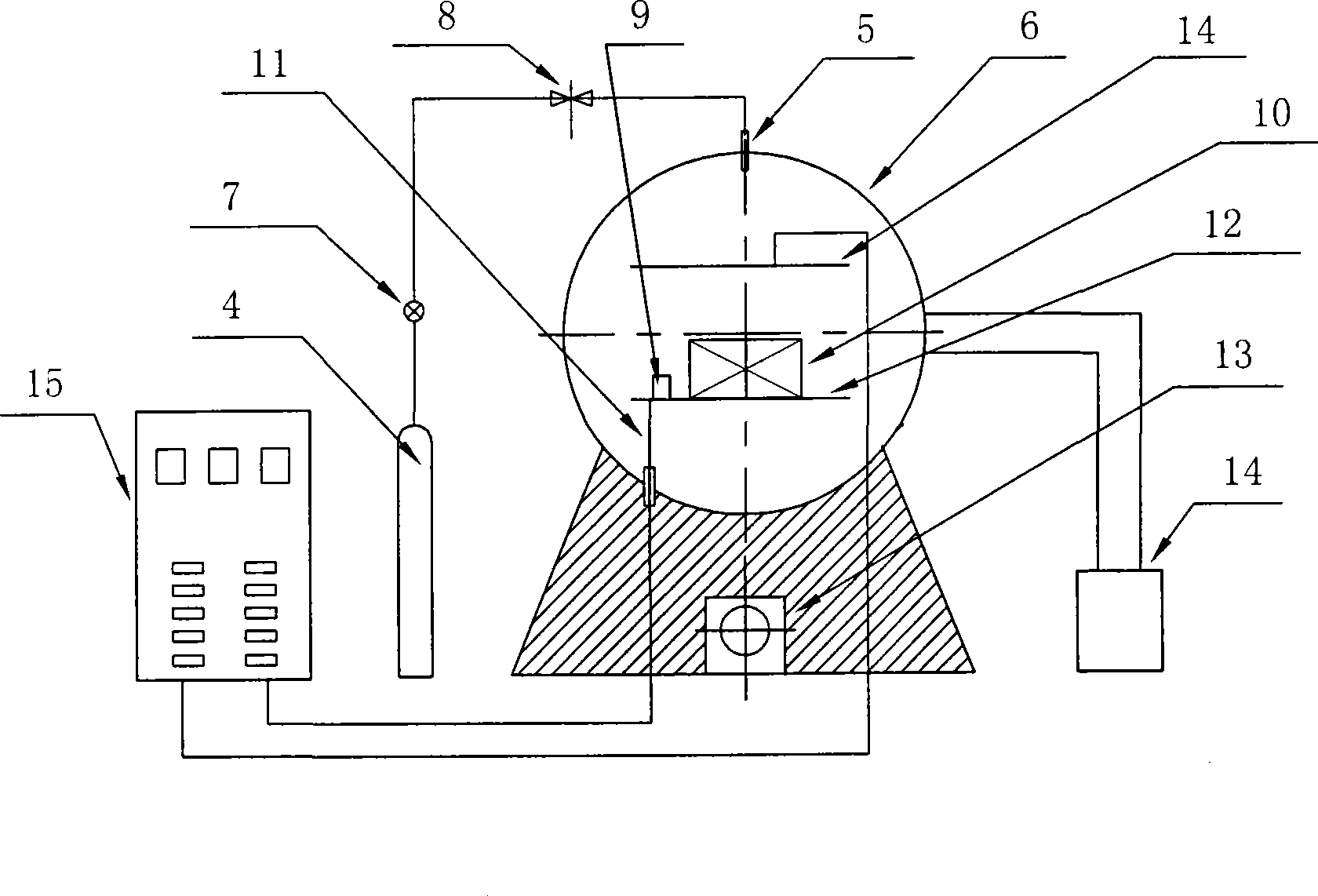

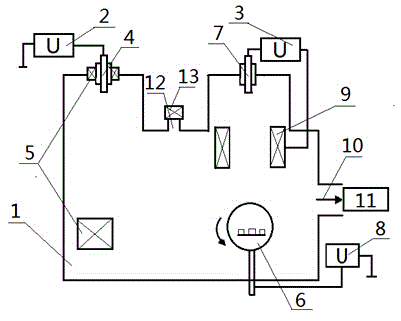

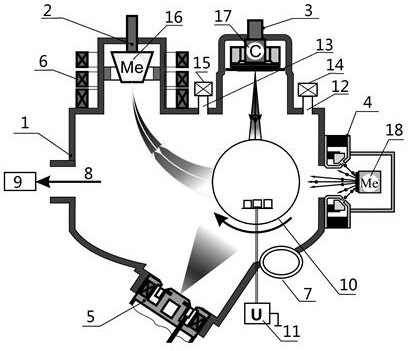

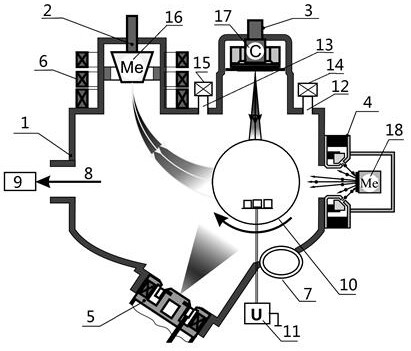

Device and method for preparing high-toughness amorphous carbon based multiphase hybrid film

ActiveCN111850484AHigh bonding strengthReduce interface stressVacuum evaporation coatingSputtering coatingRadio frequency magnetron sputteringPlasma technology

The invention discloses a device and a method for preparing a high-toughness amorphous carbon based multiphase hybrid film. The device is a radio frequency magnetron sputtering auxiliary direct current and pulse cathode arc multi-excitation-source plasma coating device. The preparation method comprises the following steps: drying a pretreated substrate, placing the substrate on a rotary sample table of a multi-excitation-source plasma coating device; vacuumizing, filling argon in a vacuum chamber, and carrying out sputtering washing on the surface of the substrate by using an ion source; and taking high-purity metal aluminum, titanium and graphite flakes as magnetron sputtering target materials and direct current and pulse cathode arc evaporation target materials, filling argon gas and nitrogen gas, designing a multiphase hybrid film structure according to formation laws of nanocrystals and amorphous phases, adjusting the rotating speed of the sample table, and introducing functional doped elements and a gradient intermediate layer by using a multi-excitation-source plasma technology to prepare the amorphous carbon based multiphase hybrid film. The prepared amorphous carbon based multiphase hybrid film is adjustable in structure and controllable in phase composition distribution, and has high hardness, high adhesion strength and high toughness.

Owner:TAIYUAN UNIV OF TECH

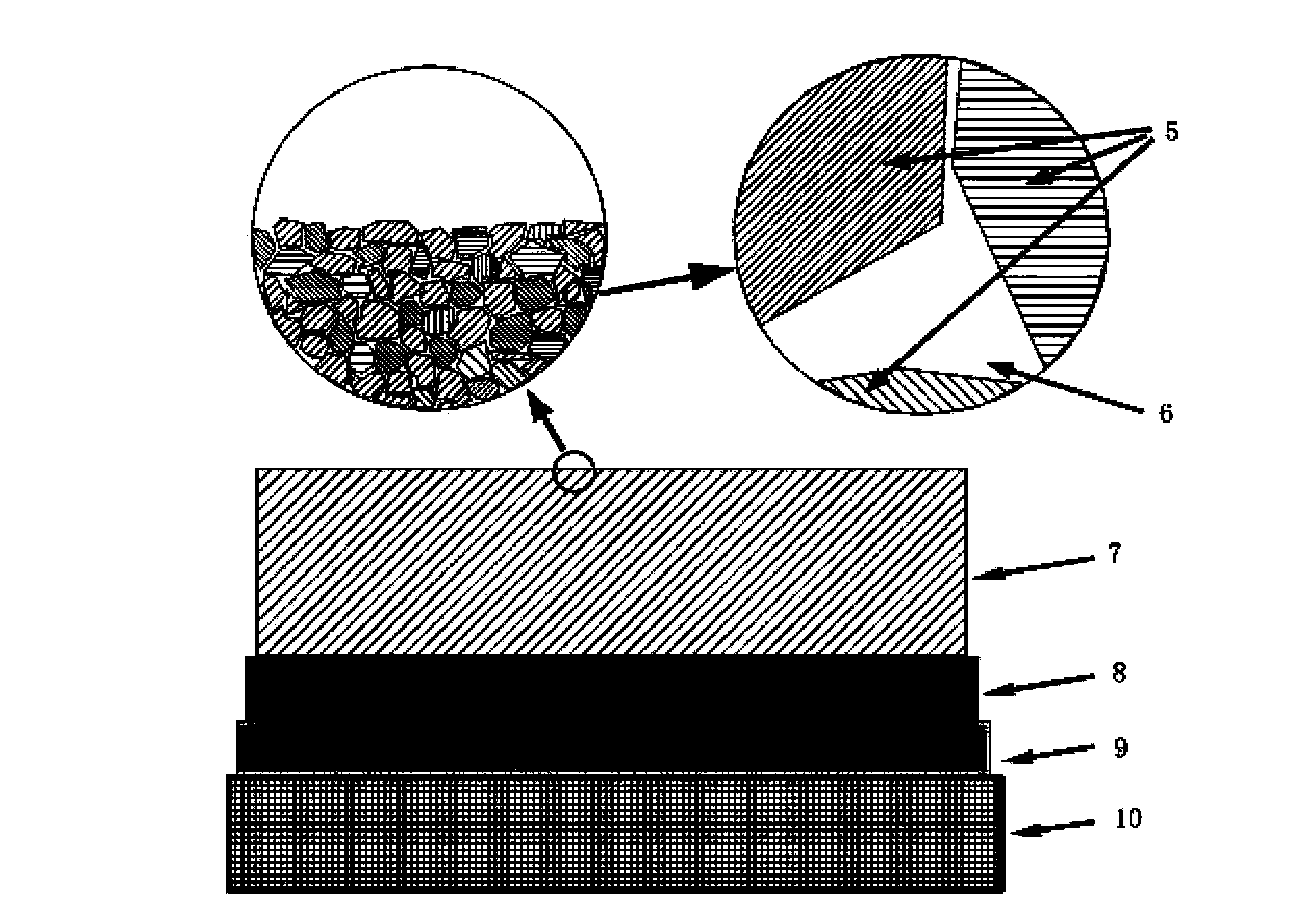

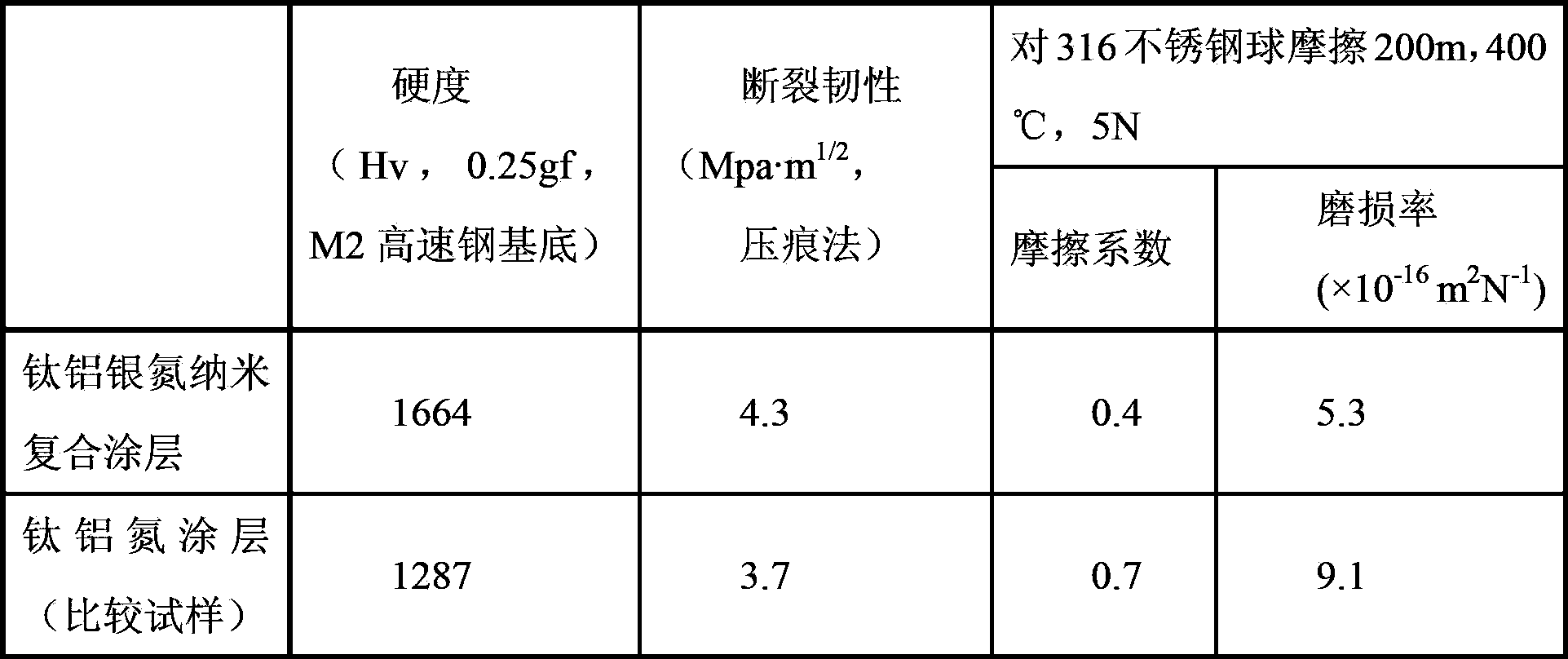

Titanium-aluminum-silver-nitride nano composite coating and preparation method thereof

InactiveCN103774089AInhibition of solid solutionHigh hardnessVacuum evaporation coatingSputtering coatingHigh fractureAlloy substrate

The invention provides a titanium-aluminum-silver-nitride nano composite coating and a preparation method thereof. The titanium-aluminum-silver-nitride nano composite coating is characterized by mainly comprising titanium-aluminum-nitrogen nanocrystal particles with the particle diameter of 8-33 nm and silver distributed between crystal boundaries of the titanium-aluminum-nitrogen nanocrystal particles, and comprises 3-8 at.% of silver, 45-50 at.% of nitrogen and the balance of titanium and aluminum. The preparation method comprises the following steps: step 1, vacuumizing after metal or an alloy substrate is packed into a cavity of coating equipment, heating, stabilizing, and introducing Ar; step 2, enabling a sample table to rotate, starting substrate voltage bias, and then starting a chrome target starting power supply for sputtering; step 3, introducing N2, and linearly increasing the flow of the N2 according to time to control the flow ratio of Ar / N2; step 4, starting a titanium-aluminum target starting power supply, quickly increasing the density of titanium-aluminum target current, and simultaneously increasing the density of silver target current; step 5, sequentially turning off the titanium-aluminum target, the silver target and a substrate heating power supply, and closing the introduction of the N2; step 6, taking out a coated sample. The titanium-aluminum-silver-nitride nano composite coating has higher hardness and higher fracture toughness, and is smaller in friction coefficient and lower in wear rate at the environment with the temperature of 400-600 DEG C.

Owner:CHINA WEAPON SCI ACADEMY NINGBO BRANCH

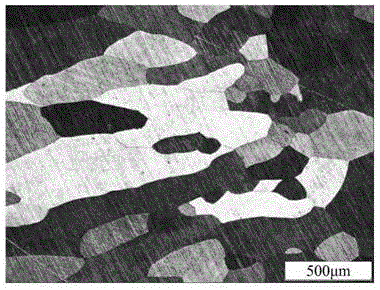

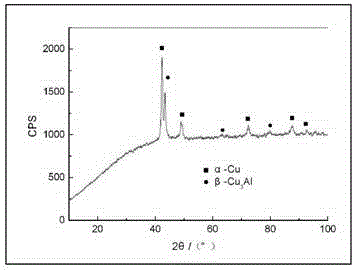

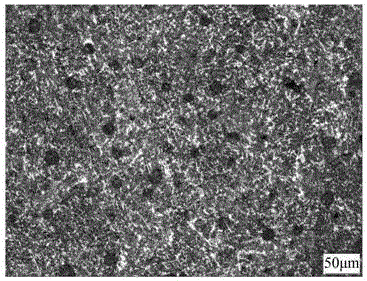

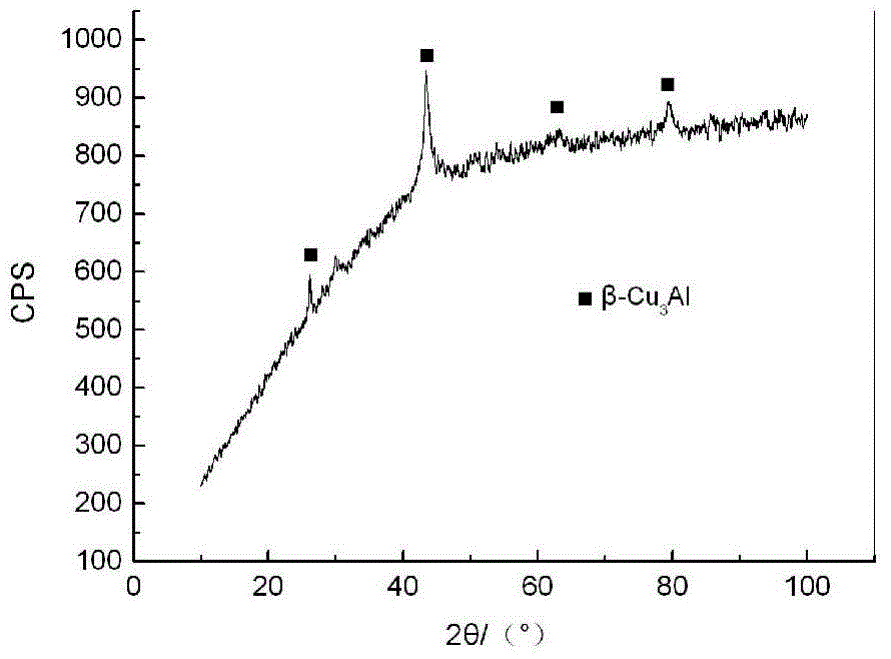

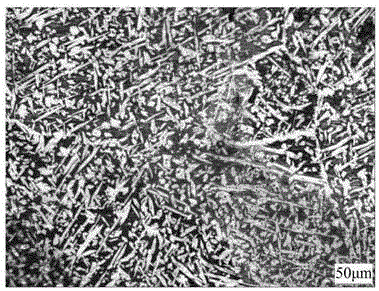

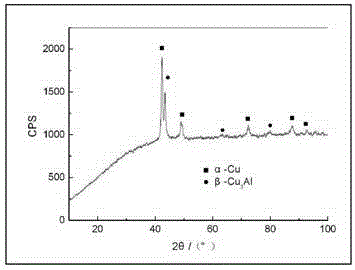

A high-strength friction-reducing and wear-resistant manganese-aluminum bronze alloy

A high-strength antifriction and wearable aluminum-manganese bronze alloy is prepared by using Mn, Al, Fe, Zn, Ce, Si, B and Cu as ingredients, and performing casting, hot forging or hot rolling machine-forming; the mass percent of all elements in the high-strength antifriction and wearable aluminum-manganese bronze alloy is 8-10 percent of Mn, 8-10 percent of Al, 1.5-2.5 percent of Fe, 1.5-2.5 percent of Zn, 0.4-0.8 percent of Ce, 0-3 percent of Si, 0-0.4 percent of B and the balance of Cu. The high-strength antifriction and wearable aluminum-manganese bronze alloy overcomes the defects that babbitt metal is low in fatigue strength, and poor in heat resistance, and the adhesion resistance, the compliance, the embedded hidden performance of a copper base alloy and an aluminium base alloy are easily improved in a bad lubrication environment, solves the traditional industry problem that toxic metal such as lead and cadmium causes environmental pollution easily, has relatively high mechanical strength and carrying capacity, is suitable for manufacturing ideal high-strength antifriction and wearable material of components of a friction motion pair under the complex working conditions, such as high speed, heavy load, high temperature and corrosive mediums in industries, such as machinery, metallurgy, energy and chemical engineering, and for example, is suitable for manufacturing a sliding bearing, a worm gear pair, a sliding block, a shaft sleeve, a transmission nut and other components.

Owner:HUNAN UNIV OF SCI & TECH

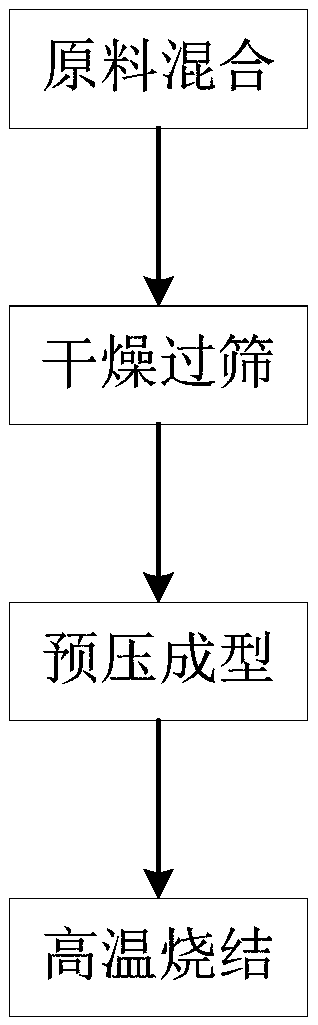

Composite ceramic mold and method for thermal bending forming of 3D glass

InactiveCN109437948ARich sourcesAntioxidantGlass reforming apparatusComposite ceramicAluminum silicate

The invention is suitable for the technical field of ceramic materials and provides a composite ceramic mold and a method for thermal bending forming of 3D glass. The method comprises the following steps: mixing the raw materials: 55-75 parts of zirconium silicate, 20-30 parts of boric oxide, 5-10 parts of silicon carbide, 4-10 parts of aluminum silicate, 1-3 parts of magnesium oxide, 1-3 parts oflanthanum oxide, 2-5 parts of titanium oxide, 2-5 parts of zinc oxide, 3-7 parts of calcium sulfate whisker, 10-20 parts of nano carbon black, and 10-20 parts of graphite, mixing proportionally, adding the materials into an ethanol solution and a phenolic resin, intensely stirring and mixing evenly to obtain a mixed slurry with certain viscosity; drying and sieving: drying the mixed slurry for 2.5-3 hours in a drying oven of 90-110 DEG C, sieving to obtain a composite powder body; prepressing and forming: putting the composite powder body in a graphite mold, prepressing at 8-12 MPa in a moldpressing former and forming; sintering at the high temperature: sintering the preformed graphite mold at the high temperature in a vacuum hot-pressing furnace, wherein the highest sintering temperature is 1550-1950 DEG C, the pressure is 25-45 MPa, the heat preservation time is 35-55 minutes, and the defects of poor oxidation resistance and poor wear resistance of the graphite mold are overcome.

Owner:仙游县元生智汇科技有限公司

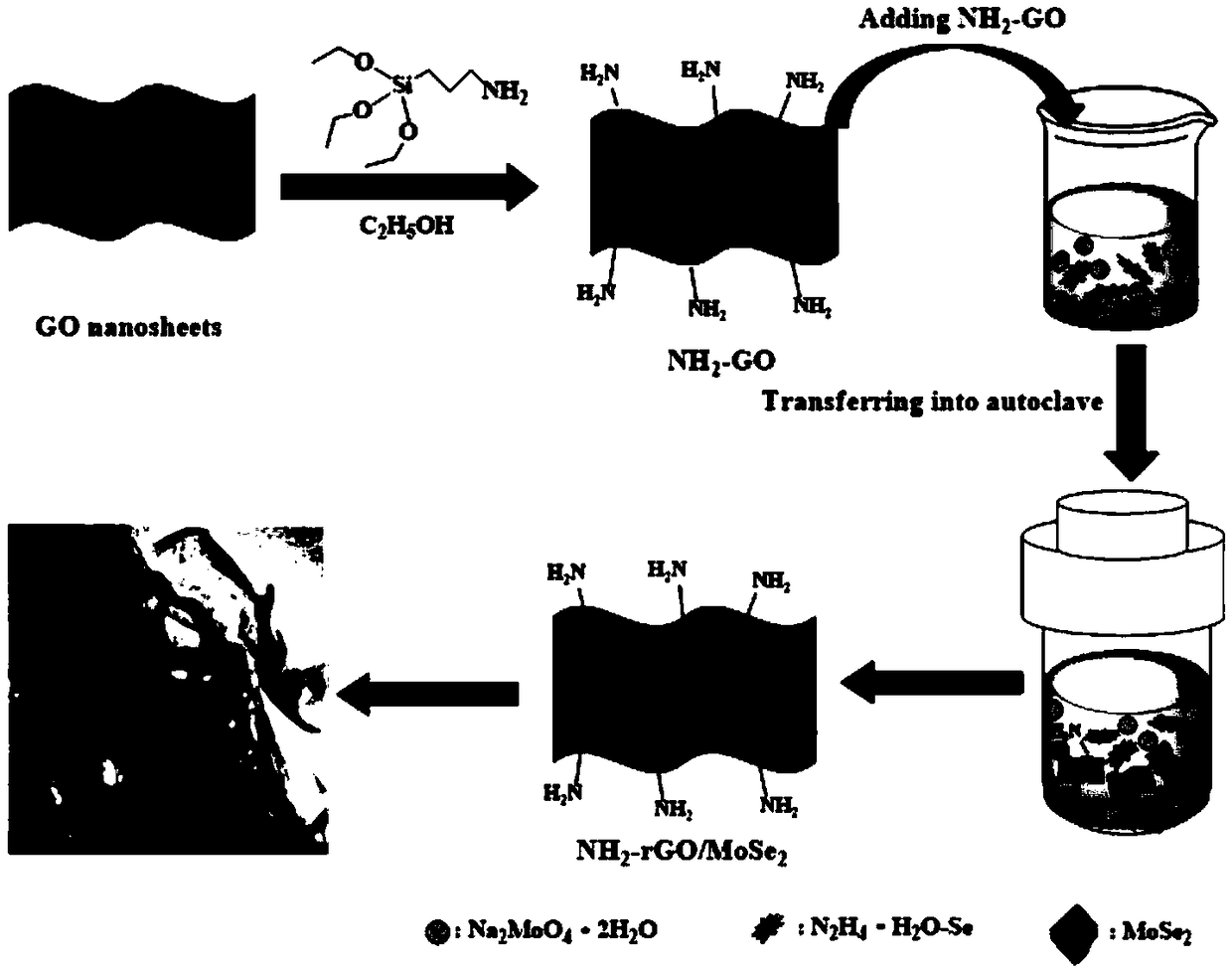

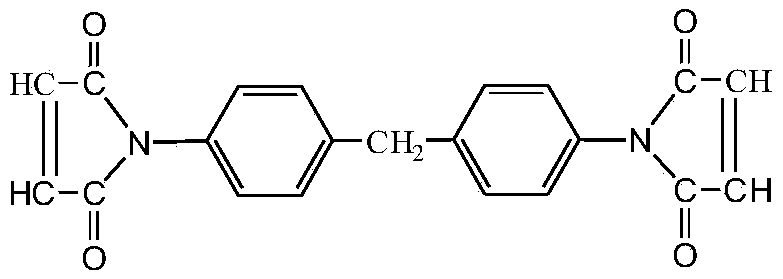

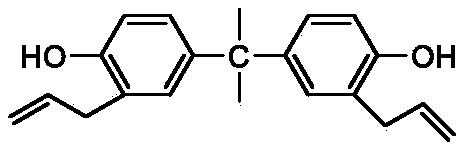

Amino-modified grapheme / graphene MoSe2 / bismaleimide composite material and preparation method thereof

The invention relates to an amino-modified grapheme / graphene MoSe2 / bismaleimide composite material and a preparation method thereof, and belongs to the technical field of advanced composite materials. Firstly, the surface of the graphene oxide is modified by using a silane coupling agent KH-550 to carry an active amino group, and then is mixed with the Na2MoO4 2H2O and the selenium powder dissolved in N2H4 H2O, and the amino-modified graphene / graphene molybdenum diselenide nano composite particle is prepared by a one-pot hydrothermal method. And finally, the prepared nano composite particles are mixed with the diphenylmethane-type bismaleimide and the diallyl bisphenol A in a certain proportion to prepare the composite material. The prepared composite material has good interface bonding strength, excellent mechanical property and tribological performance.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Hydrophobic antifriction self-lubricating carbon film based on low-temperature glow plasma and preparation method of hydrophobic antifriction self-lubricating carbon film

ActiveCN113265641AEasy to prepareLow cost of preparationSolid state diffusion coatingChemical vapor deposition coatingCarbon filmCarbon source

The invention relates to the technical field of carbon film preparation, in particular to a hydrophobic antifriction self-lubricating carbon film based on low-temperature glow plasma and a preparation method of the hydrophobic antifriction self-lubricating carbon film. The preparation method comprises the following steps: polishing a material, placing the material in a plasma nitriding furnace, vacuumizing to 10-50 Pa, switching on the voltage, keeping the voltage at 600-800 V, and keeping the duty ratio at 30%-80%; and introducing carbon source gas and hydrogen / argon, adjusting the temperature and air pressure in the furnace, starting to prepare the hydrophobic antifriction self-lubricating carbon film, keeping stable parameters such as temperature and air pressure for a period of time, then cooling a sample to room temperature along with the furnace, and taking out the sample. According to the hydrophobic antifriction self-lubricating carbon film based on the low-temperature glow plasma and the preparation method of the hydrophobic antifriction self-lubricating carbon film, the problem of how to prepare the carbon film with hydrophobic and antifriction self-lubricating characteristics at low temperature at low cost is solved.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

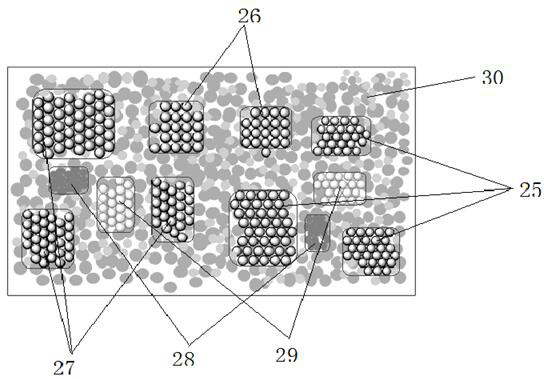

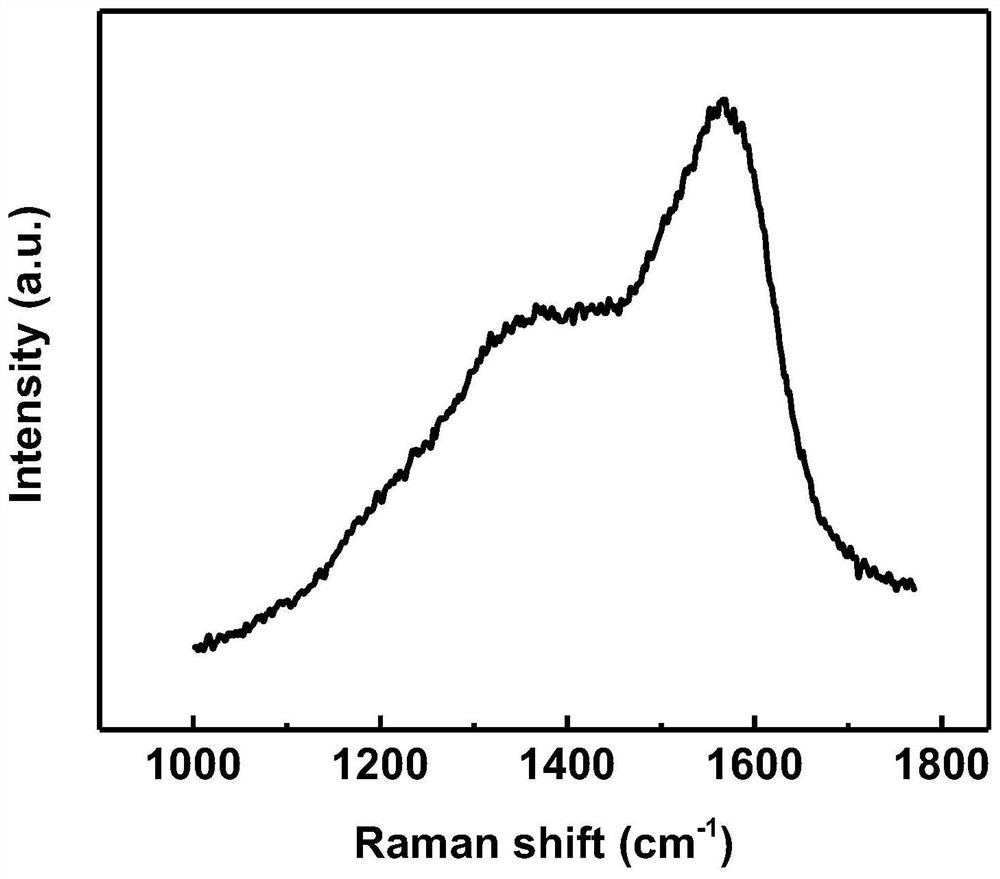

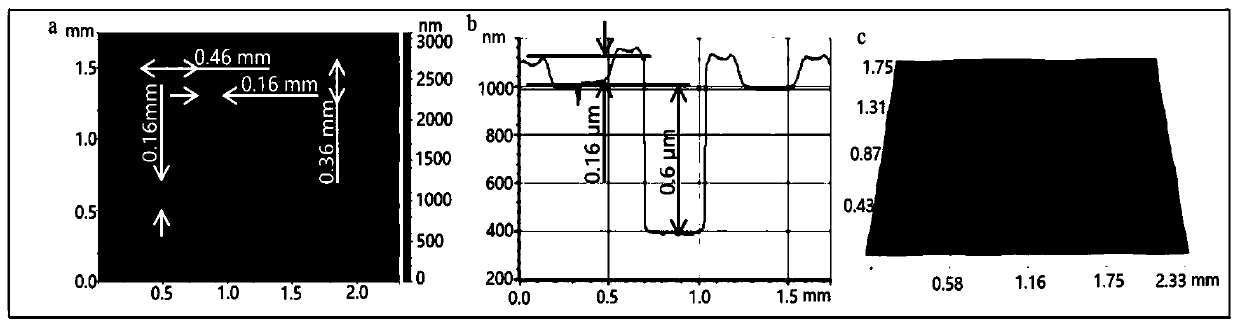

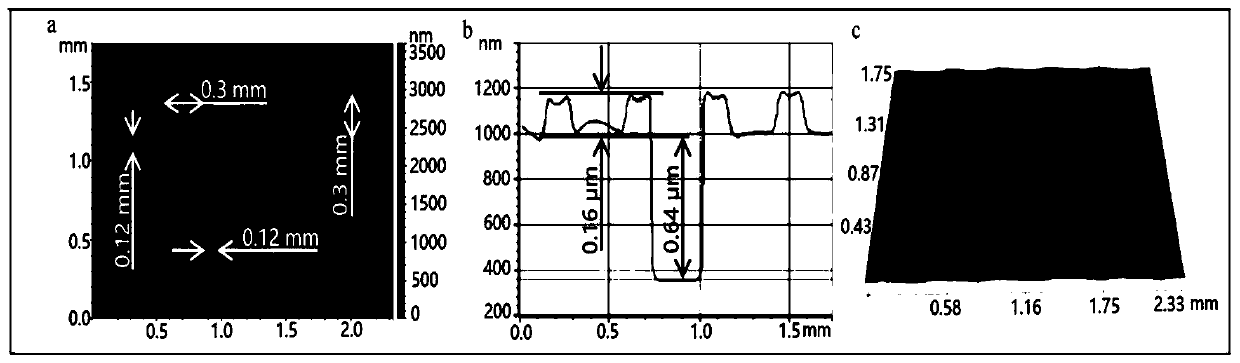

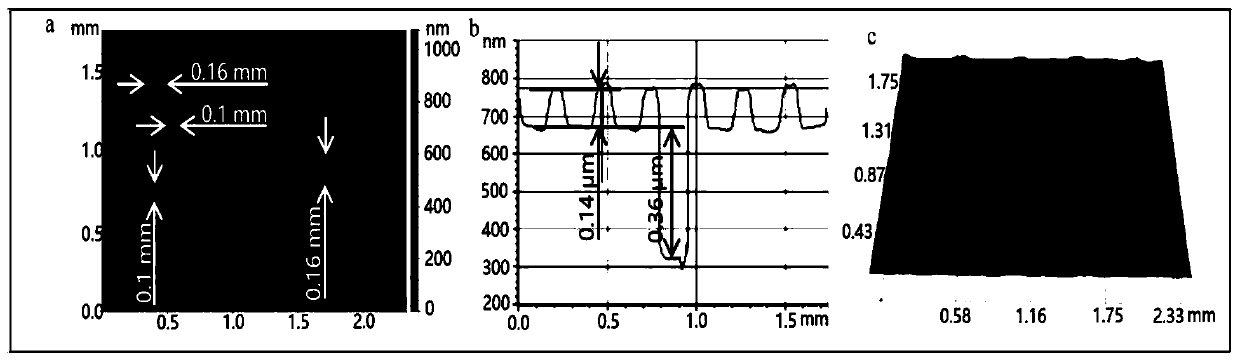

Textured diamond-like carbon-based film and preparation method thereof

ActiveCN111139430AHigh densitySimple and convenient in situ preparationVacuum evaporation coatingSputtering coatingSurface engineeringDiamond-like carbon

The invention provides a textured diamond-like carbon-based film and a preparation method thereof, and belongs to the field of surface engineering. According to the preparation method, a method of shielding the surface of a metal matrix through a metal mesh is provided, the textured DLC film is simply and conveniently prepared in situ, the metal mesh on the surface of the metal matrix is not tightly attached to the matrix, a certain gap is reserved between the metal mesh and the matrix, and the size of the gap is strictly controlled; the gap is utilized to realize the redistribution of plasmadensity of the deposition space, so that the plasma density at the gap between shielding region of the metal mesh and the matrix is increased, and the deposition rate at this region is increased; thedeposition rate of the non-shielded region is unchanged, so that the film thickness of the shielded region is greater than that of the non-shielded region, and a textured surface layer is formed in situ in the film deposition process; and the film itself is continuous and complete, no uncovered area exists, and the shape, the density and the depth of textured pits can be controllably adjusted through regulation and control of the deposition process.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY +1

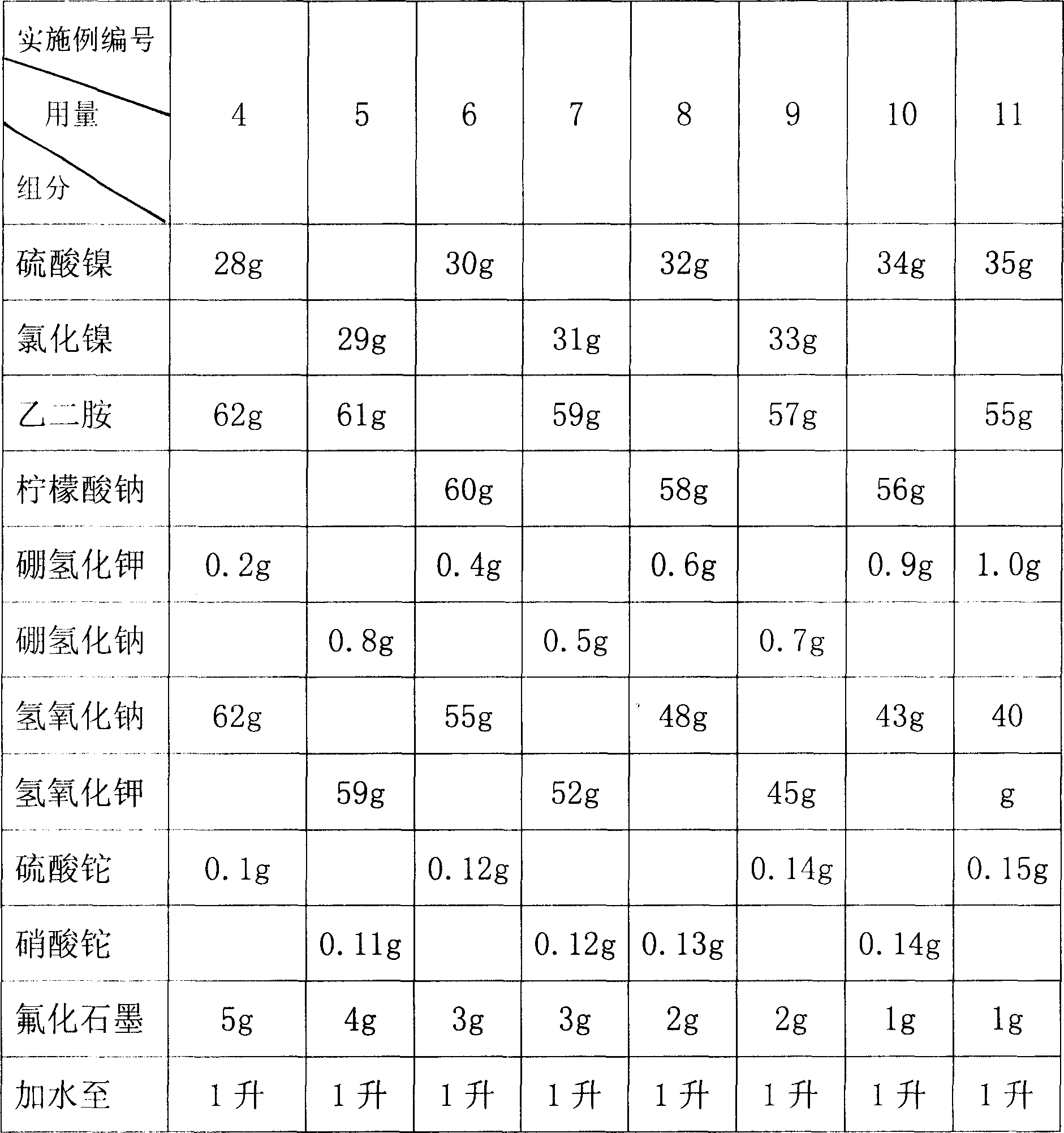

Chemical plating solution for preparing composite coating resistant to fretting damage and chemical plating method thereof

InactiveCN1827849AUniform thicknessHigh surface hardnessLiquid/solution decomposition chemical coatingChemical platingPotassium borohydride

The invention relates the method for preparing antifriction damnification composite deposite chemical plating liquid, comprising the following characters: 28-35g / L nickelous sulfate, 55-62g / L ethanediamine, 0.2-1.0 g / L potassium borohydride, 40-62g / L caustic soda, 0.1-0.15g / L thallium sulfate, 1-5g / L graphite fluoride; cleaning and activating the surface of work, putting the work into chemical plating liquid at 12-14 PH and 80-88Deg.C for 10-60 min. The Ni-Tl-B / (CF)n the composite deposite made by the said method has the advantages of homogeneous thickness, good association, high hardness, strong blocking resistance and good corrosivity.

Owner:SOUTHWEAT UNIV OF SCI & TECH

A high-performance friction-reducing and wear-resistant manganese-aluminum bronze alloy

The invention relates to a high-performance antifriction and antiwear manganese-aluminum-bronze alloy. According to the technical scheme adopted by the invention, the high-performance antifriction and antiwear manganese-aluminum-bronze alloy is prepared from Mn, Al, Fe, Zn, Ce and Cu by casting and hot forging or hot rolling. The elements of the high-performance antifriction and antiwear manganese-aluminum-bronze alloy comprise 5-10% by mass of Mn, 6-10% by mass of Al, 1.5-2.5% by mass of Fe, 1.5-2.5% by mass of Zn, 0.4-0.8% by mass of Ce and the balance of Cu. The high-performance antifriction and antiwear manganese-aluminum-bronze alloy provided by the invention can be used for overcoming the defects of low fatigue strength and poor heat resistance of babbitt and increase of seizure resistance, compliance resistance and embedment resistance of copper-based alloy and aluminum-based alloy in poor lubrication environment and solving the traditional problem in the field that toxic metals such as lead and cadmium can cause pollution to environment easily. In addition, the high-performance antifriction and antiwear manganese-aluminum-bronze alloy can function as the antifriction and antiwear material of all parts and components of a friction motion pair used in complex conditions of high speed, heavy duty, high temperature and corrosive media in the machinery industry, metallurgy industry, energy industry and chemical industry and can be used for preparing parts and components such as sliding bearings, worm gears, sliding blocks, shaft sleeves and driving nuts.

Owner:HUNAN UNIV OF SCI & TECH

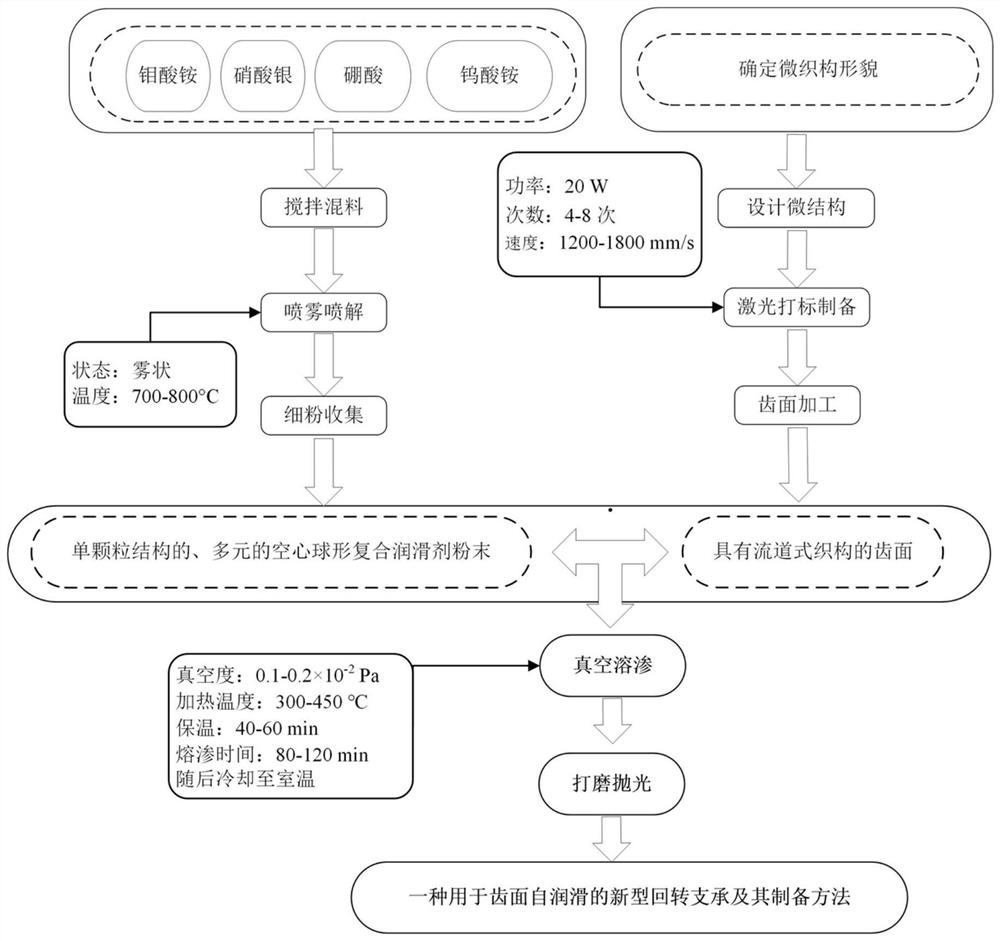

Novel slewing bearing for tooth surface self-lubrication and preparation method of novel slewing bearing

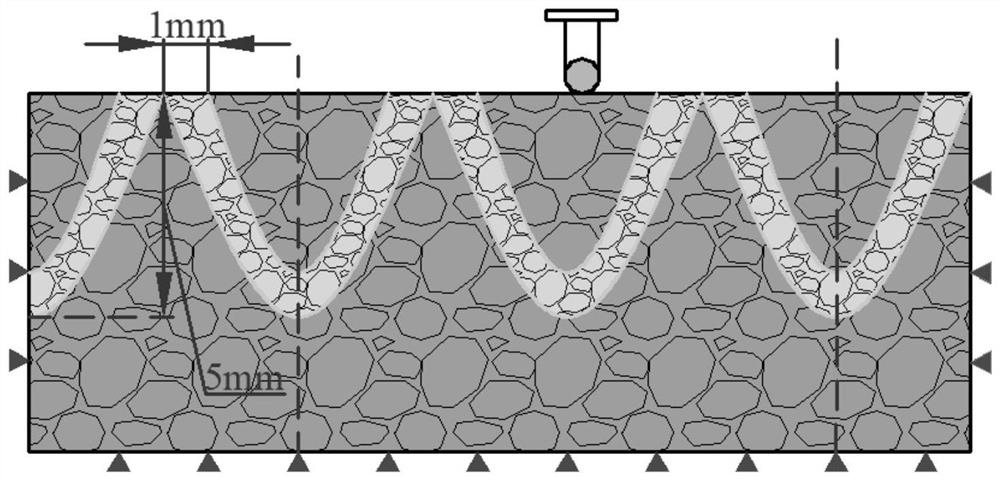

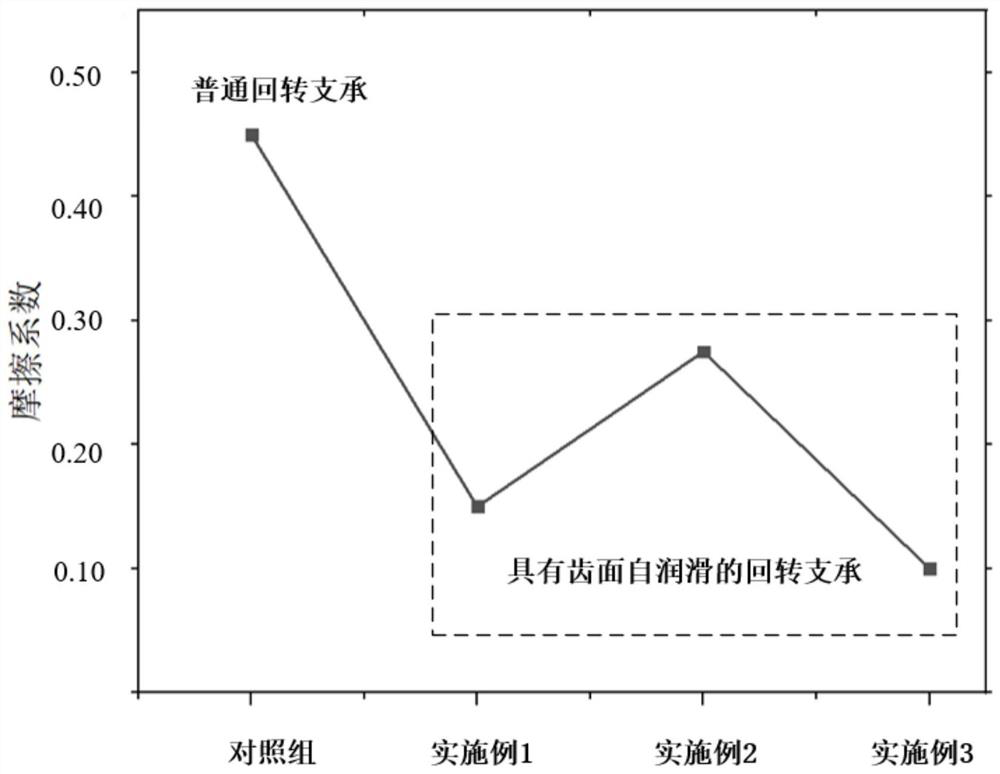

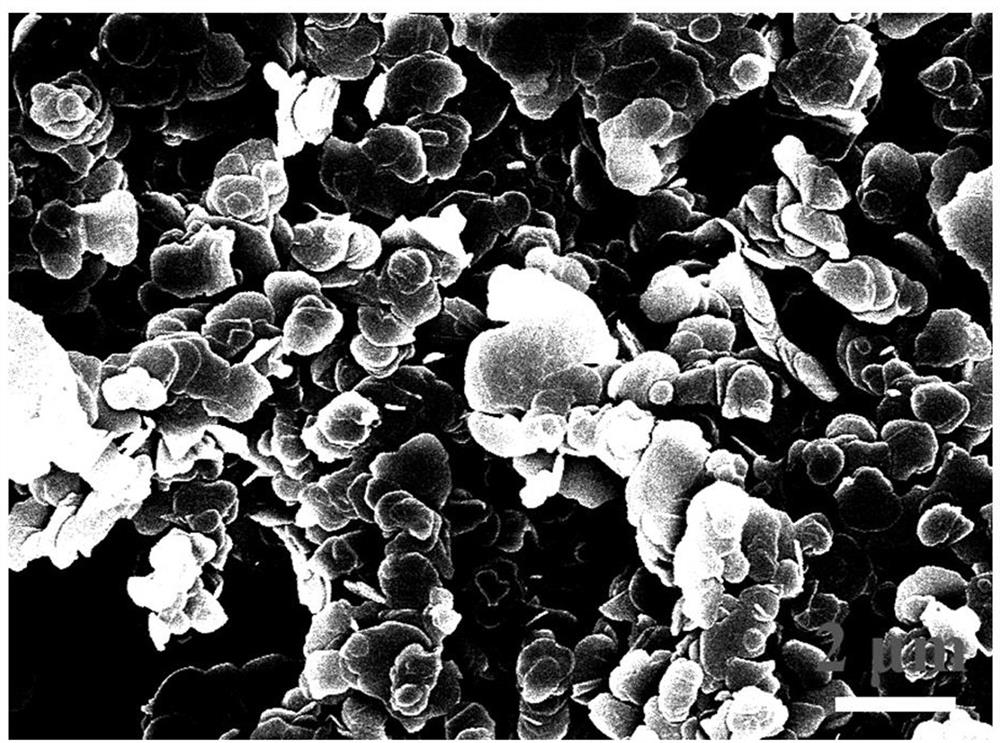

PendingCN114083230AImprove tribological propertiesReduce coefficient of frictionTransportation and packagingMetal-working apparatusLubricationMaterials science

The invention discloses a novel slewing bearing for tooth surface self-lubrication and a preparation method of the novel slewing bearing. A flow channel micro-texture is machined on the tooth surface of the slewing bearing through a laser marking technology, a solid lubricant can be more fully spread on the surface of a base body through the bionic micro-texture, so that a layer of lubricating film is formed, and the effects of reducing friction and reducing material abrasion are achieved. the composite solid lubricant is multi-element hollow spherical composite lubricant powder with a single-particle structure, and is prepared by spraying a mixed solution of ammonium molybdate, silver nitrate, boric acid and ammonium tungstate into a high-temperature atmosphere of 700-800 DEG C in a vaporific manner and carrying out thermal decomposition synthesis. The composite spherical power, serving as the solid lubricant phase, fills the micro-texture through vacuum dissolution and permeation, so that the obtained tooth surface is provided with a self-lubrication composite material with a self-lubrication phase. Compared with a traditional slewing bearing, the novel slewing bearing with the tooth surface self-lubrication function has the advantages of excellent friction reduction and wear resistance, low friction coefficient, low wear rate, higher use stability and longer fatigue life.

Owner:XUZHOU WANDA SLEWING BEARING

Modified polyphenylene sulfide and preparation method thereof

PendingCN114836035AHigh strengthImprove insulation performanceManufacturing dynamo-electric machinesGlass fiberMeth-

The invention provides a preparation method of modified polyphenylene sulfide, which comprises the following steps: preparing ZIF-8 / BN: adding boron nitride into a mixed solution of an organic solvent and water, uniformly mixing, ultrasonically and centrifugally taking an upper solution, and freeze-drying to obtain a boron nitride nanosheet; the preparation method comprises the following steps: dispersing boron nitride nanosheets in methanol, adding zinc nitrate hexahydrate and 2-methylimidazole, and standing at room temperature to obtain ZIF-8 / BN; preparing modified polyphenylene sulfide: mixing polyphenylene sulfide, glass fiber and ZIF-8 / BN, and then extruding and granulating; the mass ratio of the polyphenylene sulfide to the glass fibers to the ZIF-8 / BN is (55 to 80): (10 to 40): (1 to 5). The ZIF-8 modified BN and the glass fibers are used for synergistically modifying the polyphenylene sulfide, so that the strength and the temperature resistance of the polyphenylene sulfide are improved, and the polyphenylene sulfide has a longer service life in a high-temperature environment, and can be used for preparing the coil framework of the voice coil motor.

Owner:兰州中科聚润新材料有限公司

A device and method for preparing a toughened amorphous carbon-based multiphase hybrid film

ActiveCN111850484BHigh bonding strengthReduce interface stressVacuum evaporation coatingSputtering coatingRadio frequency magnetron sputteringPlasma technology

The invention discloses a device and a method for preparing a toughened amorphous carbon-based multi-phase hybrid film. The device is a radio frequency magnetron sputtering assisted direct current and pulse cathodic arc multi-excitation source plasma coating device. The preparation method includes: drying the pretreated substrate and placing it on the rotating sample stage of the multi-excitation source plasma coating device; Vacuumize, introduce argon gas into the vacuum chamber, and use ion source to sputter and clean the surface of the substrate; use high-purity metal aluminum, titanium and graphite sheets as magnetron sputtering targets, direct current and pulse cathodic arc evaporation targets respectively , enter argon and nitrogen, design multi-phase hybrid film structure according to the formation rules of nanocrystalline and amorphous phases, adjust the sample stage speed, and use multi-excitation source plasma technology to introduce functional doping elements and gradient intermediate layers to prepare amorphous carbon heterogeneous hybrid films. The amorphous carbon-based multi-phase hybrid thin film prepared by the invention has adjustable structure, controllable phase composition distribution, high hardness, high adhesion strength and toughness.

Owner:TAIYUAN UNIV OF TECH

Aqueous epoxy adhering solid lubricant

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

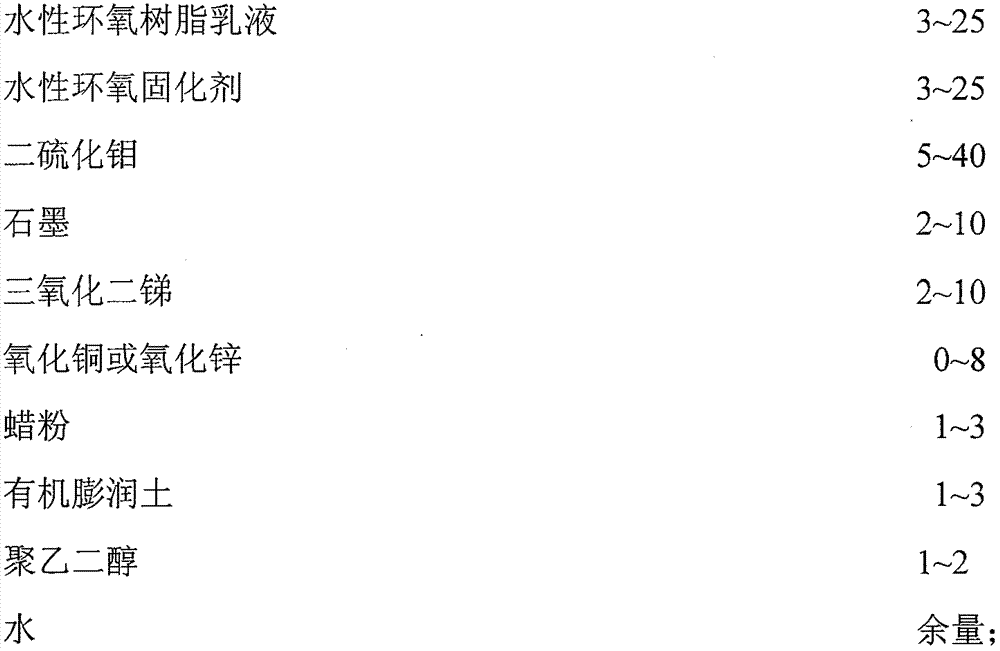

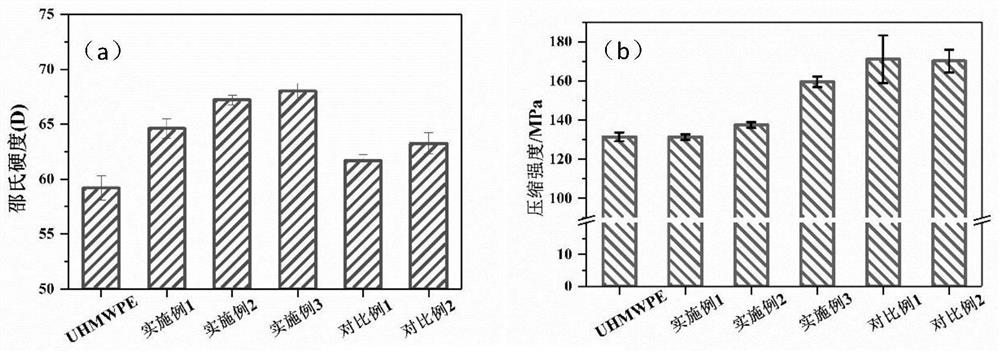

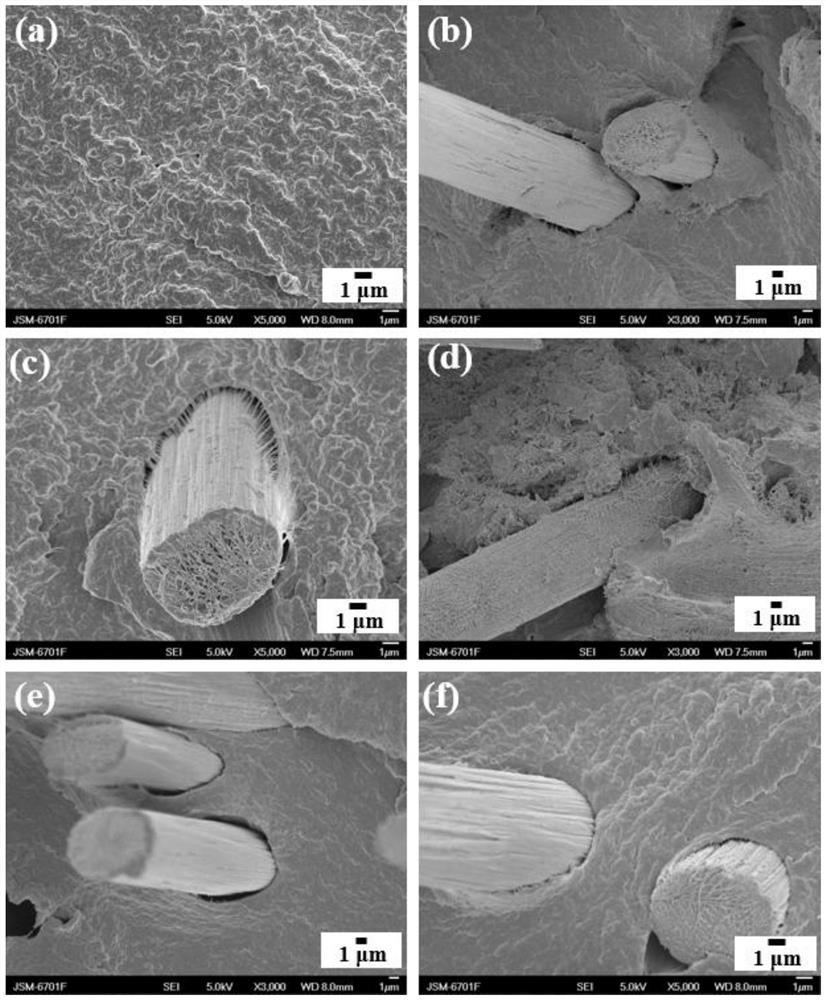

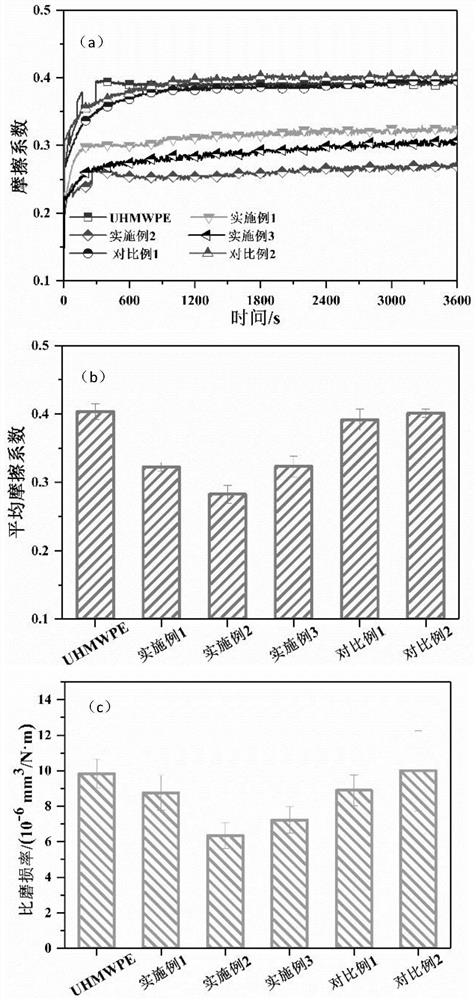

Polyetherimide-attapulgite-carbon fiber hybrid material and its preparation method, modified uhmwpe and its preparation method

The invention provides a polyetherimide-attapulgite-carbon fiber hybrid material and a preparation method thereof, modified UHMWPE and a preparation method thereof, belonging to the technical field of solid lubricating materials. The interfacial bonding between the polyetherimide-attapulgite-carbon fiber hybrid material prepared by the present invention and the UHMWPE matrix is good, and the polyetherimide-attapulgite-carbon fiber hybrid material is used for modification of UHMWPE to obtain The modified UHMWPE has excellent anti-friction and wear resistance properties.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Zirconium oxide-based nano ceramic tool and die material added with titanium boride and preparation method thereof

InactiveCN101798216BGood anti-friction and wear resistanceImprove mechanical propertiesFriction reductionNanoceramic

The invention relates to a nano ceramic tool and die material and a preparation method thereof. The ceramic tool and die material is sintered from yttrium stabilized nano ZrO2 serving as matrix, added micro TiB2 and micro alpha-Al2O3 serving as enhancing phases and micro molybdenum, nickel and magnesium oxide serving as sintering aids. The preparation method comprises the following steps: dispersing the nano ZrO2, micro TiB2 and micro alpha-Al2O3 powder respectively, ball-mixing and drying the power to obtain a powdery material, and sintering the powdery material by adopting a hot-pressing method. The method is favorable for improving the mechanical property of the material, and has the advantages of simple preparation, convenient operation and the like. The obtained nano ceramic tool anddie material has good comprehensive mechanical property, friction reduction and abrasion resistance, and can be used for manufacturing cutting tools, dies and other abrasion and corrosion resistant parts.

Owner:QILU UNIV OF TECH

Modified polyetherimide material, preparation method thereof and cable support

The invention provides a modified polyetherimide material, a preparation method thereof and a cable support, and belongs to the technical field of insulating materials. The preparation method of the modified polyetherimide material provided by the invention comprises the following steps: coextruding polyetherimide, glass fibers and two-dimensional boron alkene to obtain the modified polyetherimide material, the mass ratio of the polyetherimide to the glass fibers to the two-dimensional boron alkene is (60-80): (10-30): (1-5). The MBene and the glass fiber are introduced into the PEI cable support, so that the strength and the high-temperature resistance of the PEI cable support are effectively improved under the condition of ensuring excellent insulativity of a device.

Owner:兰州中科聚润新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com