Textured diamond-like carbon-based film and preparation method thereof

A diamond and textured technology, applied in metal material coating process, ion implantation plating, coating, etc., can solve the problems of high cost and complicated process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The invention provides an in-situ preparation method of a textured diamond-like carbon-based film, comprising the following steps:

[0033] Fixing a metal grid on the surface of the metal base, the gap between the metal grid and the surface of the metal base is 50-200 μm, and obtaining a metal base covered with the metal grid;

[0034] Using the Cr target as a sputtering target, performing closed-field unbalanced magnetron sputtering on the metal substrate covered with a metal grid on the surface to form a Cr bonding layer;

[0035] Using the Cr target and the C target as sputtering targets, preparing Cr→Cr on the surface of the Cr bonding layer x C y Gradient transition layer, the x gradually decreases, and the y gradually increases;

[0036] With the C target as the sputtering target, in the Cr→Cr x Cy Magnetron sputtering is performed on the surface of the gradient transition layer to form a C layer to obtain the textured diamond-like carbon-based film.

[0037] ...

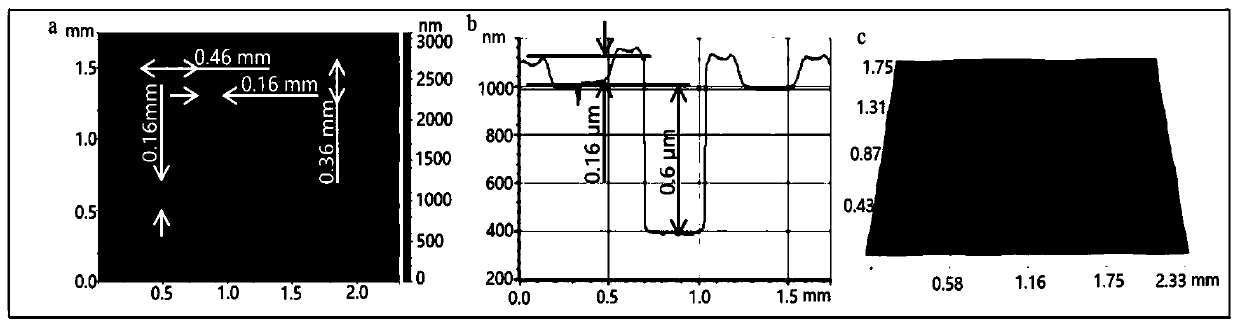

Embodiment 1

[0057] (1) Grind and polish the surface of the 316L stainless steel substrate step by step until the surface roughness Ra≤0.2 μm, then ultrasonically clean it with acetone and absolute ethanol for 15 minutes respectively, the ultrasonic temperature is 25°C, the ultrasonic power is 600W, and the metal substrate (1 );

[0058] ⑵Use acetone and absolute ethanol to ultrasonically clean the metal grid with a grid shape of 0.46 mm, a grid width of 0.46 mm, a grid spacing of 0.16 mm, and a thickness of 150 μm for 20 minutes, respectively, with an ultrasonic temperature of 25 ° C and an ultrasonic power of 600W, after drying with nitrogen gas, fix it on the surface of the metal substrate (1) with specific fixtures, and strictly control the gap between the metal grid and the surface of the substrate to be 100 μm.

[0059] (3) Fix the metal substrate covered with the metal grid on the surface obtained in the step (2) on the sample holder of the closed-field unbalanced magnetron sputteri...

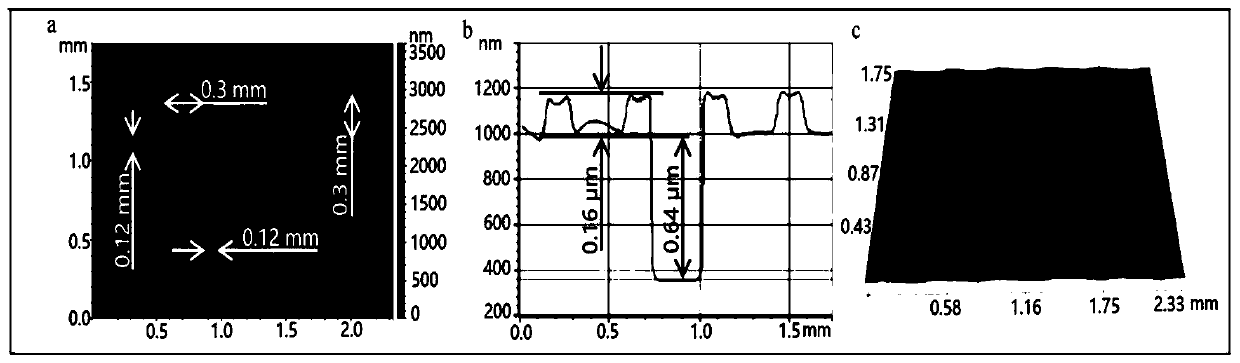

Embodiment 2

[0065] (1) Grind and polish the surface of the 316L stainless steel substrate step by step until the surface roughness Ra≤0.2 μm, then ultrasonically clean it with acetone and absolute ethanol for 15 minutes respectively, the ultrasonic temperature is 25°C, the ultrasonic power is 600W, and the metal substrate (1 );

[0066] ⑵Use acetone and absolute ethanol to ultrasonically clean the metal grid with a grid shape of 0.3mm, a grid width of 0.3mm, a grid spacing of 0.12mm, and a thickness of 150μm for 20 minutes respectively, with an ultrasonic temperature of 25°C and an ultrasonic power of 600W, after drying with nitrogen gas, fix it on the surface of the metal substrate (1) with specific fixtures, and strictly control the gap between the metal grid and the surface of the substrate to be 100 μm.

[0067] (3) Fix the metal substrate covered with the metal grid on the surface obtained in the step (2) on the sample holder of the closed-field unbalanced magnetron sputtering system...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com